Calcium Silicate Board For Interior Wall Partition Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

It can be applied not only in the interior use but also in the outdoor walls. It has low water absorption rate and high impact resistant ability. These advantages make it suitable for any purposes of applications.

Product Applications:

calcium silicate board can be used for interior and exterior wall, ceiling, floor, kitchen and toilet wall panels, materials of vessel and the subway projects, sewer separating boards in high-rise building, and even for furniture lining, fire linings, billboards, lockers board etc.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

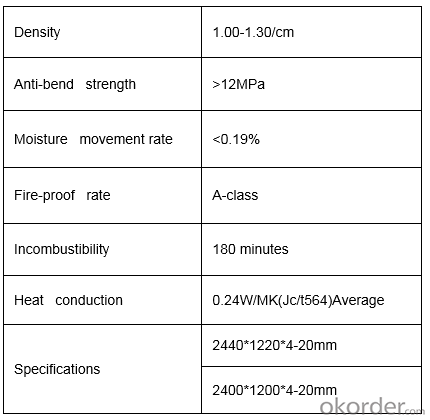

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: Cement fiber board calcium silicate board

- How to distinguish between fiber cement pressure plate and calcium silicate board 1, the density: Calcium silicate board density is much lower than the fiber cement pressure plate, through the weight of the plate can calculate its approximate density. 2, look at the color: Although there are manufacturers in order to pretend to be fiber cement pressure plate and deliberately add carbon black and other plates made dark, but not natural cement color. 3, asked whether the thin plate and thick plate, if not or can not do, it shows that he is the distribution of calcium silicate board or ordinary fiber cement without pressure plate. 4, if you go to the factory, you can visit the workshop, if steam pressure Fu (commonly known as bullet) is certainly calcium silicate board manufacturers, if there is no press, it is an ordinary cement mill.

- Q: Do the TV backdrop, there is a part of the original window, now sealed with calcium silicate board.

- You can use wallpaper, marble, diatom mud will do. If the use of marble recommended dry hanging, because the grass-roots calcium carbonate plate has a water absorption, can not achieve the condensation strength.

- Q: Calcium silicate board wall can be directly putty putty

- Because the calcium silicate board (plate) surface is relatively smooth, directly in the calcium silicate board (plate) on the batch of putty powder prone to fall off (gray) phenomenon, first primer.

- Q: How to build calcium silicate board mill, how much money

- Specific raw materials are plant fiber mineral fiber (asbestos) cement, limestone quartz sand, etc. according to the scale of investment of millions to tens of millions.

- Q: Decorated with calcium silicate board to do the ceiling after the discovery of which contains asbestos ingredients. With the putty powder and paint brush brush is it harmful to the body only two of the impact of it?

- Asbestos has a high degree of fire resistance, electrical insulation and thermal insulation, is an important fire, insulation and insulation materials, after joining the anti-cracking effect, and some are added anti-cracking fiber. So that there is no impact.

- Q: Calcium silicate board, asbestos volatile out of cancer problems, anxious?

- Calcium silicate board with cotton and cotton board, cotton board is made of asbestos and its associated products mixed with cement, quartz sand produced from the production and use of asbestos products have been banned in the world, asbestos was inhaled through the lungs Into the blood vessels to break the snow red blood cells and cause blood diseases and other diseases. Cotton-free calcium silicate board is mixed with cement and quartz sand in the original wood pulp fiber, autoclaved curing, is currently recognized as the most environmentally friendly building plate. You would like to buy environmentally friendly sheet but did not intend to buy the most dangerous materials, if the amount is huge, you can put a decoration company or material business claims for compensation, because asbestos products are not allowed for home decoration. For the whole family's health, it is recommended that you redemption of calcium-free calcium silicate board, because of technical barriers to the problem, the current domestic production of two cotton-free calcium silicate board enterprises are located in Guangzhou and Ningbo, And board, you can understand each other.

- Q: Is it harmful to calcium carbonate on home improvement?

- Calcium silicate board consists of a variety of organic and inorganic substances, the use of advanced program-controlled equipment and flow slurry process production molding, high temperature autoclaved curing and special technology processing, is an environmentally friendly, safe, multi-functional high-level building With the plate. Product composition High-purity quartz sand + mica + perlite and other mineral fillers + plant fiber + moderate amount of low-alkali cement

- Q: Home improvement with cotton calcium silicate board how to do?

- If not, for the brand, it is not OK, with gypsum board it, although the moisture-proof fire better, but with some peace of mind. No matter what the material board, as far as possible in the market to cut well, on the one hand is convenient to transport and up and down the elevator convenient, the most important, do not leave cutting dust at home, these cutting dust anywhere in the home can be adsorbed, Will continue to flow out with the air, the decoration of the house although it looks very clean, but there is a confusion is the big dust at home, is the reason. After the installation of the installation, the board of the six sides are made on the closure, first, so that the cutting site is not easy to damp, the second is the board sealed, not because of time for a long time damp, deformation, collapse and yellow.

- Q: Calcium silicate sound - absorbing panels with what inspection lot

- Silicon calcium board is a compact board, basically airtight. Relative to the sound-absorbing panels heavier and harder. Is a sealed plate. Mainly from the sound effects. That is to stop the sound on both sides of the space in the spread of space.

- Q: What is the difference between high-density fiber cement pressure plate and calcium silicate board?

- Calcium silicate board is autoclaved, the pressure plate is autoclaved and not autoclaved, autoclaved weather resistance is better, the same pressure, the density of calcium silicate board lower, because the formula has a lighter lime, There is no cement pressure plate.

Send your message to us

Calcium Silicate Board For Interior Wall Partition Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords