Calcium Silicate Board for Interior and Exterior Walls

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

The raw materials of our calcium silicate board are combined with high-purity quartz powder, high-grade cement, high-purity slaked lime, plant fiber and other mineral substances. After mixing calcium and silicate at a certain ratio, we make the raw materials into a wet sheet , keep the wet sheet under high temperature & pressure treatment by advanced technology for 1 day, then get the final product.

Product Advantages:

Standard Size: 1220*2440mm (W*L)

Thickness Range: 5mm~30mm

Packing: Pcs/Pallet

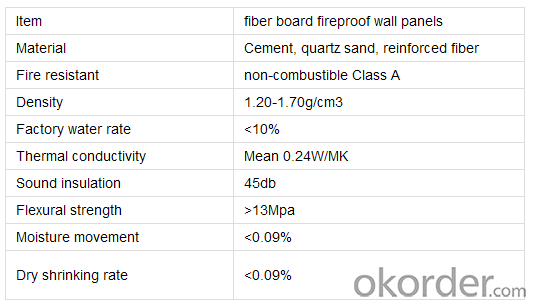

Product Parameters:

Density: 1.2~1.4g/cm3

Bending Strength: ≥10 MPA

Thermal Conductivity: ≤0.30 W/(m.K)

Moisture Content: ≤10%

Moisture Movement: ≤0.25%

Non-Combustibility: Class A

Main Product Features:

Fire Proof; High Strength & Light Weight; Easy Installation & Decoration; Fungus Proof; Resistant to Insects and Termite; Small Deformation Coefficient;

Applications:

Interior & exterior wall, ceiling, floor, kitchen and toilet wall, material of vessel and the subway projects, furniture lining, fire lining, billboards, lockers board and etc.

Product Specifications:

Images:

- Q: What is the use of high-temperature calcium silicate board? I want to find a material can be resistant to high temperature 1500 ℃, and must be pressure,

- Calcium silicate board is used for decoration, interior decoration. You said that this material should not be calcium silicate board.

- Q: What are the well-known brands of calcium silicate boards in China?

- Calcium silicate board is made of inorganic mineral fiber or cellulose fiber and other loose short fiber as a reinforcing material, with siliceous-calcium material as the main cementing material, pulping and molding, accelerating the curing reaction in high temperature and high pressure saturated steam to form Calcium silicate gel made of the plate. Is a good performance of the new building and industrial sheet, its products fire, moisture, noise, insect moth, durability is better, is the ceiling, cut off the ideal decorative plate.

- Q: Is the calcium silicate board attached directly to the wall?

- Yes, but the premise is that the wall must have a good flatness, otherwise, after the installation of the surface will be uneven.

- Q: 6.5 square machine room decoration ceiling how to count? Ceiling using calcium silicate board + steel keel, remove, block 8 nozzle

- Putty price is 5 yuan / square meter, the price of Putty putty is 5 yuan / square meter, latex main material is 12 yuan / square meter, rolling latex paint, 3-4 yuan / square meter. Coupled with the lamp with the circuit will be less than 400 yuan. Cleaning, garbage clean up, up to 200 yuan. Your area is so point. A 100-bedroom house decoration, the main material for the words, the renovation fee was 70,000. You only point area. It is not posted gold.

- Q: Indoor compartment with calcium silicate board or gypsum board is good?

- When decorating, the use of gypsum board more, calcium silicate board rarely used, generally only in the bathroom which will encounter. Gypsum board to do the wall, the construction is convenient, the price is relatively cheap.

- Q: What is the difference between calcium silicate board and gypsum board?

- Calcium silicate board as a new environmentally friendly building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, the advantages of long life, a large number of industrial and commercial construction in the ceiling ceiling and partition, home decoration, furniture The lining of the billboard, the liner board of the ship, the shelf plate of the ship, the floor of the warehouse, the floor of the network, and the wall of the indoor engineering such as the tunnel.

- Q: Decorated with calcium silicate board to do the ceiling after the discovery of which contains asbestos ingredients. With the putty powder and paint brush brush is it harmful to the body only two of the impact of it?

- Asbestos has a high degree of fire resistance, electrical insulation and thermal insulation, is an important fire, insulation and insulation materials, after joining the anti-cracking effect, and some are added anti-cracking fiber. So that there is no impact.

- Q: Calcium silicate with quartz powder is the number of requirements! How much silicon content?

- Calcium silicate board preparation of quartz powder with the general requirements: Silica content: greater than or equal to 93 (%) Melting point 1600 (℃) Mohs hardness: conventional Common specifications: 100 - 325 head Color: gray, grayish yellow Suitable for the production of calcium silicate board and other calcium silicate products

- Q: What are the extruded boards and calcium silicate board adhesives?

- Extrusion board on the requirements of the adhesive is relatively high, generally used to polymer mortar, two-component polymer mortar, and now some commercial resin powder instead of redispersible polymer powder Also has its advantages and disadvantages, its advantages are inexpensive, pre-bonding firm. Its disadvantages are slightly corrosive, late bonding is not very good. It is recommended to use two-component polymer bonded mortar (slightly higher cost) quality and reliable.

- Q: Why is silicon calcium board not suitable for use in home decoration?

- This is from the decoration style, the material is not appropriate, silicon calcium gypsum board to semi-water gypsum and silicone oil as the main material, the surface of the silicone oil with the transport installation will be out of friction, a long time will be depleted Loss, if you run JS, silicone oil coating is not full, then the moisture effect is even worse, over time the moisture, deformation, mold, yellow is sure

Send your message to us

Calcium Silicate Board for Interior and Exterior Walls

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords