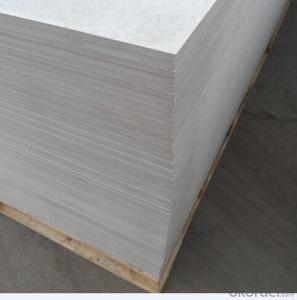

Non-Asbestos Free Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Applications:

Non-asbestos Free Fiber Cement Board

+CE certificate

+High density

+High strength

+Competitive price,high quality

1.3-1.5g/cm3 Density Non-asbestos Free Fiber Cement Board

Product Advantages:

High Density and Strength fiber cement board is a high quality calcium silicate architectural board reinforced with selected cellulose fibres and fillers. It is 100% free from asbestos, sepiolite, inorganic fibres or formaldehyde.

Thickness | 3.5mm~25mm |

Widths | 1220 mm |

Lengths | 2440 mm |

| Content of chloride ion | 0% |

| Water content | <10% |

| Water aborsption | <40% |

| Percentage of water swelling | ≤0.25% |

| Water vapour permeability | No water vapour after 24hours' test |

| Thermal conductivity | ≤0.20 W/mk |

| Thermal shrinkage | ≤0.5% |

| Fire Resistance | Incombustibility A1 Class(GB8624-2006) |

| Fire Resistance limit | ≥240minutes |

| Bending Strength | ≥10Mpa |

| Impact strength | ≥5.0KJ/m2 |

| Screw-withdrawal force | ≥60N/mm |

| Freezing resistance | No cracking and layering after 25 times of freeze thawing test |

| Sound Insulation | >46db |

| Radioactivity | <1.0lRa,<1.0lr |

| Asbestos | Asbestos free |

| Formaldehyde release | No formaldehyde |

Images:

- Q: Calcium silicate board surface smooth it? Waterproof? Can I use this board to do the outdoor door?

- Calcium silicate board is the biggest characteristic of waterproof fire, stable performance. Using the calcium silicate board to do the outdoor door is already a mature technology

- Q: Just 6mm of calcium silicate board to do smallpox will not crack

- Calcium silicate board has excellent water resistance, in the bathroom, bathroom and other places of high humidity, can still maintain the performance of stability, will not swell or deformation. Calcium silicate board high strength, 6mm thick plate strength greatly greater than 9.5mm thick ordinary gypsum board.

- Q: What is the amount of tropicin in the calcium silicate board? Or how to define? What is the effect of the content on the quality of calcium silicate board?

- This question is not a direct answer. The toe mullite is mainly composed of cement and quartz sand at high temperature and high pressure, produced in the autoclave. Of course, is a high point, increase the stability and strength of calcium silicate board

- Q: Calcium silicate board 6MM how much money one

- Calcium silicate board regardless of the thickness of the millimeter, the price of each of their manufacturers are different, according to the price of raw materials, there are different ranges of rise or fall.

- Q: Does the apartment use silicon calcium board to make the wall right?

- Because silicate to change the plate are containing quartz components, and the content is still high. Quartz is a carcinogen, long-term under the influence of this material, the human body will greatly enhance the chance of cancer

- Q: What is the use of calcium silicate board with calcium silicate board ceiling is good

- Calcium silicate board is made of inorganic mineral fiber or cellulose fiber and other loose short fiber as a reinforcing material, with siliceous-calcium material as the main cementing material, pulping and molding, accelerating the curing reaction in high temperature and high pressure saturated steam to form Calcium silicate gel made of the plate. It is a kind of new building and industrial sheet with excellent performance. Its products are fireproof, moisture - proof, soundproof, insect - resistant and durable, and it is an ideal decorative plate for ceiling and partition.

- Q: Does the calcium silicate factory pollute? What is the harm to people? Please know the big god reply! Thanks

- There are dust, waste gas, waste water pollution, calcium silicate board used lime, cement, quartz powder, chrysotile asbestos (carcinogens, most domestic enterprises are still used) and other raw materials, in the feeding, finished sanding, cutting process , Many companies ignore the dust pollution, dust removal capacity and capacity does not match, asbestos,

- Q: Hydrate calcium silicate gel under what circumstances

- Hydrated calcium silicate is hydrated by tricalcium silicate and dicalcium silicate, or an aqueous compound synthesized from a silicon-containing material and a calcium oxide-containing material.

- Q: Calcium silicate sound - absorbing panels with what inspection lot

- According to the use, the state has the best reverberation timetable for all kinds of halls, and the reverberation time of the audible field can be checked by the reverberation. With ordinary fire test whether the fire standards.

- Q: How to identify whether calcium carbonate board contains asbestos?

- Asbestos calcium silicate board broken mouth will be very fine very fine wool (is plant fiber), after the fire is lit, is the smell of wood burning, no special smell; with asbestos calcium silicate board broken mouth will have Rough wool (asbestos), with the fire lit, there will be a very special smell, like the smell of plastic burning.

Send your message to us

Non-Asbestos Free Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords