Asbestos Free Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction:

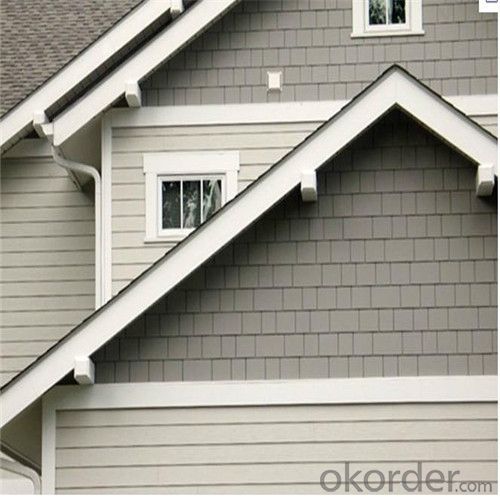

Sanle fiber cement board is made of high-grade cement and modified material, reinforced by natural fiber. Being processed by high pressure and high temperature advanced technologies, Sanle fiber cement board is a new building material with excellent performances.

Features

Fire Proof & Insulation

Class A non-inflammability, no toxic gas, low in perveance, good electric insulation material

Waterproof and Moisture Proof

In semi-outdoor area and under high temperature condition, performance of Sanle boards is stable and will not bend or deform.

Thermal Insulation and Sound Insulation

Low thermal conductivity, good heat insulation, high in density, sound proof

Light weight & High strength

Pressured by 5000-ton hydraulic machine, it is high in strength and light in weight. It is not easy to deform and bend, and good for flooring and roofing.

Easy installation

The installation of boards is dry operation, which is faster. It can be processed with ordinary wood working tool. The board is easy to be processed.

Economical and Good looking

The boards are light in weight. Together with the use of keels, they can save cost of construction and decoration. The painting is uniform, and the surface is smooth, making the exterior of buildings good-looking and attractive.

Safe and Harmless

Test result of Sanle boards is better than national radiation protection standards of building materials. The radiation from Sanle boards is equal to that from the lawn 20 meters away from the building. The lifespan of Sanle boards is very long, and they are resistant to acid and alkali, moisture and insects. The toughness and strength remains the same when time passes by. So they can be used for a long time.

Easy to install and easy to replace

Sanle boards can be drilled, cut, engraved, nailed, painted and covered by tiles or sticker when necessary..

Product parameters

Item | Unit | Requirement | ||||

Medium density | High density | |||||

Density | g/cm3 | 1.2<D≤1.5 | 1.5<D≤2.0 | |||

Water absorption | % | ≤30 | ≤25 | |||

Non-combustibility | GB 8624-2006, grade A | |||||

wet expansion | % | ≤0.25 | ||||

Beding strength | dry | MPA | Strength grade class III | 20 | Strength grade class IV | 24 |

Saturation with water | 12 | 14 | ||||

Applications

Exterior side boards, indoor partition walls, sound-proof ceiling, decoration boards, complex walls, outdoor billboards, division boards and floor boards

- Q: Can the cement board plaster directly?

- Equal to 20mm can be set in the wall waterproofing mortar waterproof, if more than 20mm can be set in the decoration of the wall in the plaster, the plaster is usually set in the decoration of the wall of the plaster

- Q: Asbestos cement board product features

- Thermal insulation: low thermal conductivity, a good thermal insulation properties, high product density, good noise.

- Q: Will the cement board on the decoration be used to blow it directly?

- If the wall can be placed directly putty putty, putty on the general scraping three times; if the wall is not flat on the first use of plaster gypsum leveling, and then scraping putty.

- Q: Adhesive method of cement board and cement wall

- With liquid nails, also called non-nail glue. From the name can be judged, "liquid" that its state of existence; "nail" that its nature. Liquid nail is a strong adhesive force of multi-functional building structure strong glue. In foreign countries generally known as liquid nails, domestic called spike nails.

- Q: Outdoor use of cement pressure plate can not

- Cement pressure plate, also known as fiber cement pressure plate or cement fiber pressure plate, is a natural fiber and cement as raw material, by the pulp, forming, cutting, pressing, curing a new type of building plate. Is a new generation of "green" building materials, in the excellent moisture, fire performance based on the unique environmental protection features. It is based on siliceous and calcareous materials as the main substrate, with cellulose fiber reinforced materials, mixed with other auxiliary materials, through the copy forming, high pressure curing the formation of a new type of building materials.

- Q: how to make cement backer board for bathroom wall tiling?

- the old way was using wire mesh nailed to studs and a mud (concrete type) mixture applied to the mesh. After that dries tiles can be applied. Cement board is so much easier faster and not messy compared to old way. Tile stores, hardware stores and Big box hardware stores sell the cement boards

- Q: I have laid ed cement board down but I did not stagnate the boards.Will this affect the ceramic tile.?

- Hi! I just finished up my bathroom and luckily staggered my cement boards so that I would not have four boards meeting at a single spot. Here's a question for you. Did you use latex modified thinset and cement board tape to seal the joints (similar to what you would do for drywall seams)? The reason I ask is that most cement board manufacturers recommend it. If you did this, that should help prevent some of the problems that could crack your tiles. Also, did you apply dryset mortar or latex-modified thinset between your plywood subfloor and cement board before screwing the cement board down? I understand that this layer is mostly meant to make sure that there is a level surface between these two surfaces, which should help prevent cracking. If you followed these measures, I think you need to make a judgment regarding how flat the seams are where boards come together. Take a piece of tile or other flat surface and put it over the seams. If the tile is relatively flat across the seam, then I think you can leave it alone. If it isn't flat, I would fix it now...spend the extra $10-15 a sheet now and save money later by not having to redo it! I think this is the sort of situation where someone has to be there to make the call!

- Q: I'm pulling up the linoleum and replacing it with ceramic tile, 12x12. it's a small bathroom, on the 2nd floor.Under the linoleum is wood. Do i need to lie down cement board before I put the mortar mix down? Or will it be fine to put tiles on the mortar mix on the wood?

- To begin with, I would pull up all the floor decking down to the joist, and make absolutely sure all joist are good. Once that's done and i have determined all to be good, i would lay down a 3/4 plywood. I would use a floor grade tongue and groove. You could use treated plywood, but its really not needed as long as you take all necessary steps during the remodel. After you lay down your cement board, make sure you grout the joints of the cement boards and allow to dry before applying thinset for the tiling, this helps to make moister barrier. make sure you seal the tile grout joints after laying the tile. make sure the sealer has ample time to dry. proper installation of the wax ring on the toilet is very important. make sure the toilet sits flat after installation and that it does not rock. use a good silicone caulk around the tub and the base of the toilet as well. you might also reseal the grout joints every year or so because alot of floor cleaners on the market can deteriorate the sealer. just a side note; if you can put a glass of water on the floor and when you walk on the floor and the water moves, the floor has what is call spring in it. all this means is that in time all the springing action in the floor can cause hairline cracks in the grout joints thus providing a channel for water. if this is the case then seal regularly. hope this helps

- Q: FC fiber cement plate can be affixed to the aluminum plate?

- Our kitchen and toilet partition ah, closet ah, the ceiling ah, the floor, ah and many other aspects can be used fiber cement board, so now as long as there is a building where you can use fiber cement pressure plate, and fiber cement board is now in the market On the night market uneven, only the choice of high-density fiber cement board is the most reliable, most competitive materials.

- Q: Is a vapor barrier needed behind cement board in a shower?

- on an exterior wall you will need vapour barrier

Send your message to us

Asbestos Free Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords