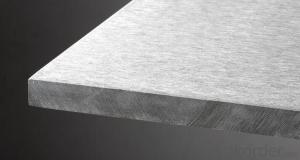

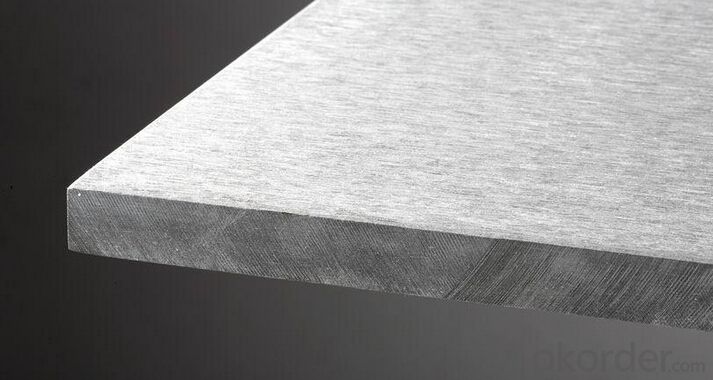

Exterior Wall Decorative Fiber Cement Board construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

5. Q: If we need samples for customer approval, will it be possible?

A: Of course we can.

6. Q:How to guarantee the quality?

A:Laboratory, integral testing process from raw materials to finished product until loading containers will be done by our factory.

Images:

- Q: I am trying to anchor a woody climbing wall to a cinder block garage wall and have settled on anchoring boards into the cinder blocks then building from there. so anything anchored there would be sharing a load of me-200 lbs, the plywood base and frame - 50lbs. plus any force generated by my jumping around on it.

- This Site Might Help You. RE: is there a cinderblock or cement anchor that will hold lots of weight? 200 lbs plus? I am trying to anchor a woody climbing wall to a cinder block garage wall and have settled on anchoring boards into the cinder blocks then building from there. so anything anchored there would be sharing a load of me-200 lbs, the plywood base and frame - 50lbs. plus any force generated by my...

- Q: How to brush latex paint on the cement board

- Cement wall: clean the wall. Brush 1 times the interface agent: brush interface agent must have to brush, and to brush uniform. Crack treatment: Under normal circumstances with kraft paper and white latex paste cracks (but can not guarantee 100% will not crack). Leveling (including the yin and yang angle straight): rugged wall needs leveling, the general gypsum is more commonly used, not less than 0.5 cm uneven difference is better.

- Q: Where is the cement pressure plate installed?

- Light keel plus cement pressure plate: Formal method: only use three light keel plus two pieces of cement pressure plate production. Light Gang keel did not make the frame, but played a connection role. This is not strong enough. But the provincial workers expected material. Formal methods: the use of light keel made of frames, after the supervision and acceptance by the Party, and then sealed cement pressure plate, linked to steel wire mesh, and finally paste the disk. Features: not easy to deformation, nowadays the most commonly used company decoration process. Plastic buckle plate, plastic aluminum plate production: These two methods for home decoration finished, and want to wrap up the riser. Because it is not necessary to fill the disk, it is convenient. Plastic buckle: wood keel plus angle, directly from the bottom of the buckle up into the installation. Disadvantages: not beautiful. Aluminum-plastic plate: wood keel on the nail nine PCT board, and then all the glue to the aluminum-plastic plate stick to a variety of colors, close to the disk effect. Disadvantages: aluminum-plastic plate angle is easy to crack, should use thicker plate.

- Q: Will Titebond II (weatherproof) work? I have a 1928 home and am trying to duplicate one of the original exterior window sills to go on a new window. I need to glue a couple of 5/4 pieces together to get the right thickness and I want it to last. The originals have redwood but it's old growth I believe and more stable than what I can find now in redwood or DF. Correct me if I'm wrong there. Plus I have only two attaching points to work with on either side of the window so I chose the fiber cement product for it's stability. Nothing on James Hardie's site says what can be used to glue it with though.ThanksThanksChris

- I would use gorilla glue which is 100 percent waterproof. or you could use polyurethane caulk which is very tough.

- Q: how much space should i be giving over my tub? ill be infront of the bath tub lip because of some issues trying to make everything flush.ive heard to just butt it up against the tub, but then ive heard give a 1/8 of a space for grout. any1 know?

- If there is a lip on the tub that is usually around an 1/8 thick I use thin strips of wood to fur out the stud creating a flat smooth surface from the ceiling to the top of the tub. Then the tile backer is screwed to the studs and leave approx 1/8 clearance at the bottom to avoid any water that may eventually creep under if the caulk fails from wicking up into your backer. You could use the end of a paint stirring stick on the tub to create the small space I am suggesting. I haven't used cementatious backer board ( WonderBoard or Durock) in the last 10 years. I have found the best product for ease of installation and durability is Hardiebacker. It is a little more than the cement boards but worth every penny. You can cut it using a circular saw, use drill bits, and hole saws without destroying your tools like cement board and get even cuts without the cement falling out like the other boards. Use their Backer On screws, NOT drywall or deck screws. Half inch Hardibacker also mates up with 1/2 drywall utilizing 1 5/8 screws. This system has worked well for me on hundreds of tile jobs over the last decade.

- Q: What is the prc in the building?

- Prestressed reinforced concrete

- Q: I have a porch that is currently covered in green turf carpet. I'd like to rip off the turf, clean the cement and mortar on small stone pavers. I will be placing the stones not only on the top, but the sides, and tread and risers of the stairs as well. Can I mortar directly onto the cement or should I use backer-board? If a backer-board is needed, how do I connect the backer-board onto the concrete? Will I need special screws?

- You do not need backer board since it is concrete. Just clean the concrete good with a garage floor cleaner and rinse and let dry. Try to do this when the hot sun is not beating down on the concrete. Use thinset mortar and a notched trowel to put it on. Figure out what kind of pattern you are goint to lay-maybe just regular common end to end? Put thinset on an area about 3' x 3' and push your pavers down into it and wiggle them just a little - after you have set some take a 4' level and a rubber mallet - tap on top of level until all the pavers are setting about the same, then move level to next row repeat. If you have some thinset on and you want to stop or take a break - just scrape it of with putty knife and put back into your mortar bucket. Cover mortar bucket with lid or damp cloth when your not getting into it. Cut pavers with a 4-1/2 grinder with a diamond blade. Watch your bottom step- you may need to cut pavers on this step down or this step may be higher than all the others.

- Q: Gypsum board, cement board, glass magnesium board to do the kind of good ceiling

- Conventional ceiling or gypsum board is the best, easy to cut easy to shape.

- Q: Can I just paint a stone on a cemented fiberboard?

- These two are good decorative plate, its hardness, fire, acid and alkali, corrosion resistance, weather resistance are better, are the first choice of real stone base material, these two are suitable for spraying real stone paint. You need to consider their own use, and the cost of local products, do the choice!

- Q: Ok, here's the situation:I have a covered porch on our house, and I need to replace its floor. Facts of concern: * It is a covered porch. There are four columns between the floor and roof, but I don't know whether they are actually supporting the roof. * It is currently floored with 1/2 plywood, which is rotting. No standing water involved; the texture prevents proper drainage and led to rot. * Under the porch is a basement room complete with wiring and such. We had planned to use oak tongue-in-groove, but have been warned away from it. Now we’re not sure what to use – we just know we don’t want to use plywood.Our questions:1. If I assume those beams are supporting the roof, I’ll need a jack. But what jack? Where do I rent one?2. I thought about using a thin plywood layer under some cement board, but what could I put on top, other than tile?3. Anybody have any other ideas for flooring? Where to get TIG cedar in Cleveland?Thanks!

- With your situation of having a room below your choices are very limited. First I would replace the rotted plywood with 5/8 pressure treated tounge and groove. You can cut to within a 1-1/2 of your exterior walls with a skill saw, I wouldn't worry to much about what is under the walls. Replace plywood and then top with 1/4 tile backer board and tile it. Complete your project by sealing your joints. If you need a jack, use the jack for your car, there usually rated for 20000 lbs

Send your message to us

Exterior Wall Decorative Fiber Cement Board construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords