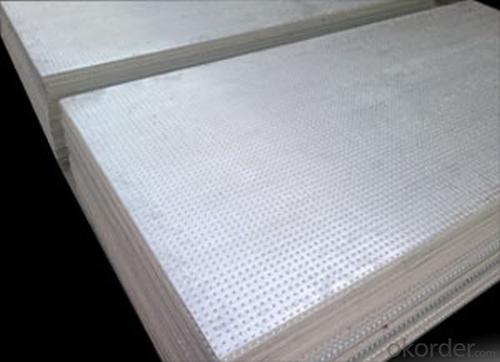

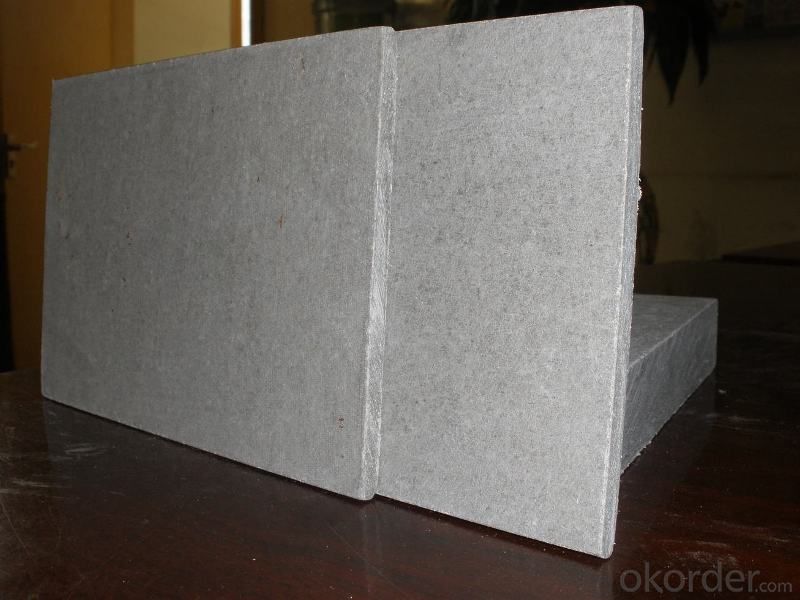

Exterior Wall Decorative Fiber Cement Board construction/drywall

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

It's 100% free of asbestos, formaldehyde, benzene and other harmful substances and with excellent performance like high strength, large size, light weight, fire and water proofing, green and environmental friendly, high efficient and energy-saving. Therefore, this kind of new material is vigorously developed and recommended by the country.

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

5. Q: If we need samples for customer approval, will it be possible?

A: Of course we can.

6. Q:How to guarantee the quality?

A:Laboratory, integral testing process from raw materials to finished product until loading containers will be done by our factory.

Images:

- Q: What do you use under the tiles, and do you still use grout as well?

- Use sand and cement mix with water proof-er in it and use the same to grout.If you want to grout the tiles a different color mix a cement dye in the cement you are using as a grout.

- Q: What exactly are fibre cement nails and what are they used for and a description.

- Not sure your spelling is correct, but cement board such as DUROCK uses special screws for installation. No fiber cement board uses nails they all get installed with SCREWS

- Q: Can cement board be tiled?

- Of course, the decoration of this approach is also a lot of it, do not have any red brick seal again, direct plaster brick on the line.

- Q: do you use cement board behind shower walls?

- That's a good choice of materials. Greenboard (drywall with a moisture-resistant green covering) has been used in the past, but cement board is sturdier, even if a leak occurs.

- Q: I have a walk in closet with plywood pieces for a floor. Don't I need cement board installed before putting in wood flooring? Thanks for your help!!

- You would use cement board when you install tile. Plywood is fine for everything else.

- Q: Sound insulation board effect and what is relevant

- As the name implies, is to reduce the intensity of the sound source, can play this role is usually a porous material, generally common are cotton products. The most effective is the gradient of sound-absorbing cotton, the raw material is made of polyester fiber, but the density is gradient, what it means, that is, side is relatively soft, one side is hard, from soft to hard, soft side of the installation towards the source.

- Q: We are going to remove the vinyl flooring. It has a 1/4in sub floor over hardwood.

- You need 1/4 hardi board at least the seams will crack if the floor moves at all. I did a bath and there was one small 4 sq inch depression and the tile broke right at that spot in less then a week.I would say yes .I am not a pro tile man but a pro DIY guy

- Q: are you able to mountain board not only on dirt but also on surfaces like cement, for ex: a street?

- you probably could

- Q: What are the densities of tiles and cement

- In the production and processing process, wood in the wood board of wood components through non-toxic chemical mineralization after the fire produced. These treated mineralized wood components combine with the Portland cement base to increase its strength and toughness, resulting in significant structural features and excellent quality of Portland cement: fire, moisture, Corrosion, pest control, and durability. The overall structure of the wood fiber board makes it resistant to impact and easy to process. Due to the close structure, high density, wood fiber reinforced concrete board sound insulation is excellent, and affordable,

- Q: I want to install ceramic tile in my kitchen. My subfloor consists of 2x8 on 16 centers with 1/2 5 ply plywood. Will it be OK to lay 1/2 cement board directly on this or do I need to some how increase the strength of the subfloor? Any recommendations.

- you could do that and MAYBE not have a problem. but if it was me, the 1/2 would come out and 3/4 would replace it. i have done a few jobs for people that dont want to replace the 1/2 and didn't have any problems with the tile or grout lines cracking. its just up to you really. if there is ANY give at all on you floor right now, id replace the 1/2.

Send your message to us

Exterior Wall Decorative Fiber Cement Board construction/drywall

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords