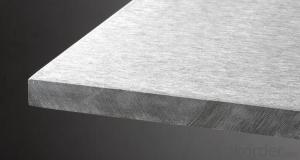

Fire Proof Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber Cement Board is mainly made of Portland cement and silicate materials as base and cellulose reinforced, forming in Hatschek process and high pressure (7000T press machine for 15 minutes) and fumigation(in autoclave for 24 hours),so it has the advantages of high strength, light weight, anti- freeze, water-resist, fire-proof, damp-proof, sound-absorption , no distortion and no radiation.Used as suspended ceiling, partition, heat insulating board, base plate, billboard, external wall panel, exterior wall cladding, paneling, moving floor, desktop board, fire-resistant air pipe ,back-liners, skirting lines, prefabricated structures, flooring, roofing, door shutters

Application: fire-rated building partition, ceilings, exterior wall cladding, sarking board, light -weight grouted panel, decorative drywall…

Sizes: 1200x2400, 1220x2440, 610x2270, 610x2440, 600x600, 600x1200, 603x603, 595x595…

Thickness: 4.5mm-30mm

Edge: square, bevelled/tapered

Materials: Tobermorite, Portland cement, Quartz sand, wood fiber…

Fire-proof rate: A-class incombustible (GB8624-1997)

Incombustibility: 240 minutes (GB/T9978-1999)

Density: 1.2-1.5g/cm3

Moisture: <30%

Heat conduction: 0.24W/MK (Jc/t564) Average

Sound-absorption: 45db (GBJ75-84)

Anti-bend strength: >12MPa (GB/T7019-1997)

Moisture movement rate: <0.3% (GB/T7019-1997)

Dry shrinking rate: <0.09% (GB/T7019-1997)

Radiation rate: According with Standard (GB6566-2001)

- Q: Miyan cement board and wood fiber cement board with the advantages of ordinary cement board

- VIVA wood cement board, FOREX US rock cement board is produced by Thailand to import a new type of decorative building materials wood wood cement board, the United States rock cement board is made by Portland cement and mineralized plant fiber, plant fiber High pressure and made of high density cement pressure plate. Wooden cement board, the United States rock cement board on the market are the existing plate are all in one: wood cement board, the United States rock cement board with multi-purpose, can be used in the building inside and outside the wall, floor, ceiling, wet light Partition walls, doors, furniture, have a good aesthetic effect,

- Q: Redoing my tub and shower tearing it out and instaling new walls and tile thanks.

- I would go for the cement board where the tile is going to be in the tub/shower area and the green board elsewhere in the room.

- Q: Outdoor doors of the aluminum-plastic plate can be directly in the waterproof cement board paste it?

- can. But when the aluminum-plastic plate, then a long time will be knocked up. After all, the wind and sun is just a matter of glue

- Q: What is the national standard for the thickness and hardness of indoor residential cement?

- The choice of the wall will generally consider whether there is sufficient strength and stability, thermal insulation requirements, fire and moisture requirements, sound insulation requirements. The city's building is generally 24 walls or 37 walls, the rural area is generally the majority of 18 walls

- Q: Why does the fire burn on the cement board for a long time?

- Cement is a bad bad conductor, prolonged heating will be uneven due to uneven heating caused by uneven expansion, eventually leading to explosion

- Q: What are the brands of cement fiberboard

- North China well-known brands: nine Germany, three music Zhejiang area: Dragon, Han Debang, love rich Greek Guangdong has: east, new elements, ete board Tibet: gold special But the manufacturers have the advantages of various manufacturers, please select the appropriate product buyers

- Q: Can anyone suggest a good way to cut small pieces (i.e. 2-4) of Hardiebacker and make it break cleanly? I can't seem to get it to break off easily unless it's bigger piece... and I was told not to use a power tool (i.e. circular saw) as it would create a ton of dust, which could be bad to breath in.

- Wet backer board as you cut it..keep water away from electrical components of saw. Dust will no be minimal.....this is a 2 man job.

- Q: How do fighters break ice, cement and wood blocks without breaking their hands, arms, legs and feet?

- Just like up said conditioning most old school martial artists used to punch wood,and kick trees to condition their hands and shins/feet they do this for many years and build a tolerance to doing it which prevents injury like punching the corner of a boxing ring the metal just punching 1000 times each day will build your knuckles and prevent the wrist from snapping and teach you not to bend wrist.Hope this helps you

- Q: Can the cement board cut off the wall directly

- Is not, even if the brush on the long time is to fall off, unless the picture is hydrophilic, it is a kind of hydraulic map, otherwise it is not enough.

- Q: Is there a easy method to apply hydraulic water stop cement to the area where the wall meets the floor without making a mess. Thank you very much

- Yes and no. The good thing is that is dries really fast and you can use a wire brush to help clean the surrounding areas after filling the crack or hole. Just don't let the mix get to dry before using the wire brush. Also, when doing this, use the coldest water and it will cure more slower.

Send your message to us

Fire Proof Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords