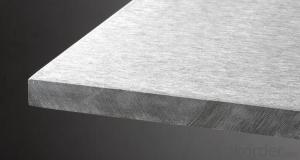

Water Proof Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction:

Sanle fiber cement board is made of high-grade cement and modified material, reinforced by natural fiber. Being processed by high pressure and high temperature advanced technologies, Sanle fiber cement board is a new building material with excellent performances.

Features

Fire Proof & Insulation

Class A non-inflammability, no toxic gas, low in perveance, good electric insulation material

Waterproof and Moisture Proof

In semi-outdoor area and under high temperature condition, performance of Sanle boards is stable and will not bend or deform.

Thermal Insulation and Sound Insulation

Low thermal conductivity, good heat insulation, high in density, sound proof

Light weight & High strength

Pressured by 5000-ton hydraulic machine, it is high in strength and light in weight. It is not easy to deform and bend, and good for flooring and roofing.

Easy installation

The installation of boards is dry operation, which is faster. It can be processed with ordinary wood working tool. The board is easy to be processed.

Economical and Good looking

The boards are light in weight. Together with the use of keels, they can save cost of construction and decoration. The painting is uniform, and the surface is smooth, making the exterior of buildings good-looking and attractive.

Safe and Harmless

Test result of Sanle boards is better than national radiation protection standards of building materials. The radiation from Sanle boards is equal to that from the lawn 20 meters away from the building. The lifespan of Sanle boards is very long, and they are resistant to acid and alkali, moisture and insects. The toughness and strength remains the same when time passes by. So they can be used for a long time.

Easy to install and easy to replace

Sanle boards can be drilled, cut, engraved, nailed, painted and covered by tiles or sticker when necessary..

Product parameters

Item | Unit | Requirement | ||||

Medium density | High density | |||||

Density | g/cm3 | 1.2<D≤1.5 | 1.5<D≤2.0 | |||

Water absorption | % | ≤30 | ≤25 | |||

Non-combustibility | GB 8624-2006, grade A | |||||

wet expansion | % | ≤0.25 | ||||

Beding strength | dry | MPA | Strength grade class III | 20 | Strength grade class IV | 24 |

Saturation with water | 12 | 14 | ||||

Applications

Exterior side boards, indoor partition walls, sound-proof ceiling, decoration boards, complex walls, outdoor billboards, division boards and floor boards

- Q: Decorative fire board environmental protection? How to choose to buy environmentally friendly decorative fire board?

- We have a new type of composite fire environmental protection decorative panels to 100% non-asbestos, A1-level fire-resistant high-density fiber cement board as the substrate

- Q: My fear is that I will trap moisture where it shouldn't be. Is there such a thing as overkill?

- No problem. i dont call it overkill. I would rather do it know than wish i had.

- Q: Can cement board be tiled?

- No need, Directly on the cement board tiling, If the cement board too light can be polished nap

- Q: Is it ok to pour floor leveling compound over hardibacker cement board?

- Yes, just make sure you've used a lot of screws to hold the backer board down or your compound will crack to pieces if the board moves at all.

- Q: I have 3/4 hardwood in the living and dining rooms and was wanting to avoid any step transitions. Any suggestions or opinions would be appreciated.

- This is a question for your local tile factory. But, 1/4 inch is rather thin. You'd have to be very careful keeping it level.

- Q: I removed a fiberglass tub and enclosure since it was damaged beyond repair. I am now installing a steel tub and am going to install an enclosure with it as well to save time with tiling. Now with the studs exposed, I would think I would put up a vapor barrier on the studs, then the durock cement board and then attach the enclosure. I know you use cement board for tiling, but if you are putting up an enclosure do I still use cement board?

- You don't need to use Durock (cement board) if you are installing a surround. You would use that if you were putting tile around the tub. Other posts mention green board, and that is what was used in the past, but it is more common now to use a wallboard that is mold and mildew resistant, such as Gold Bond XP, made by National Gypsum, which is purple. You should be able to find that, or a similar product by another manufacturer at your local building materials dealer. Good luck!

- Q: How many colors does cement have?

- A foreign reinforced concrete research institute invented a cheap and common shielding material - carbon cement. In order to make the cement conductive, in the cement added conductive properties of anthracite or coke powder. Building the building with this kind of cement makes the building itself a barrier and more secure and reliable than a metal barrier. When making conductive cement, pay attention to its high reflection coefficient, resulting in a high level of indoor electromagnetic energy. For the protection of staff and sensitive equipment, the Russian Institute of Concrete and Reinforced Concrete Science has also found a more ideal conductive cement, both a good absorption of electromagnetic radiation, but also has a very low reflection coefficient. The success of its development can reduce the cost of electromagnetic protection to the original 1%. Conductive cement can be used not only to build new plants but also as protective coatings. As the conductive cement will heat when there is a current through, this heat is safe and does not cause burning, so it can be used to build heat exchangers, drying rooms, non-icing airport runways, sidewalks and stairs, Wall of the house.

- Q: When I was replacing vanity in small bathroom, I discovered that old vanity was sitting on top of the wooden sub-floor while the rest of the floor (with ceramic tile) is about whole inch above the sub-floor. I'm planning to install tile (never did it before) and I've read that you attach cement backer board to sub-floor and use adhesive to attach tiles. However cement boards are sold in 1/2 thickness. What should I do to make whole sandwich (board, adhesive, tile) to be on the same level as rest of the tile floor? I'd much appreciate any suggestions! :)

- you can use floor leveller. you can but it at home depot,$35, follow the instuctions as far as how much water to add. it mixes into a watery slurry that levels it self once poured. it hardens as hard as cement and then you can glue your tile to it.

- Q: is there a spray on cement moisture barrier to use under laminate flooring?

- There are water block paints and such... but the cost would be too exorbitant for what you need to accomplish. ALSO.. most laminate floor manufacturers state that a 6 mil plastic sheet vapor barrier is what they require, when installing their products on concrete. (This goes on the concrete, then the foam underpad goes over the plastic sheeting) You can buy 6 mil plastic by the roll.... 10ft x 25ft, or longer.. in clear or black, and isnt that expensive. It's what the manufacturers suggest, I'd stick with it, or you're going to void your flooring warranty.

- Q: Home decoration decoration in the cement pressure board hanging wire network doing what?

- To prevent the uneven settlement of the foundation caused by wall cracks, resulting in wall cracking.

Send your message to us

Water Proof Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords