Fiber Cement Board Water Proof Type with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

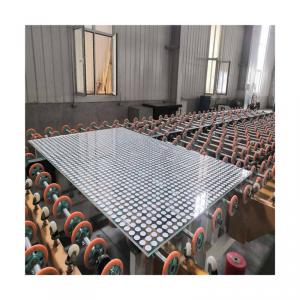

Calcium Silicate Board is mainly made of siliceous and calcareous materials as major and natural cellulose reinforced, forming in Hatschek process and high pressure (7000 tons and fumigation(in autoclave for 24 hours),Which has the advantages of high strength, light weight, anti- freeze, water-resist, fire-proof, damp-proof, sound-absorption , no distortion and no radiation Used assuspended ceiling, partition, heat insulating board, base plate, external wall panel, exterior wall cladding, paneling, flooring, back-liners, skirting lines, prefabricated structures, door shutters

Specifications

non asbestos calcium silicate board

1)Outstanding Fire Resistance

2)Efficient Thermal Resistatant

3.5 --- 12 mm wall partition ceiling decoration calcium silicate board

Specification | Size | 2440*1220mm; |

Thickness | 4.5 to 12mm | |

Surface treatment | With or without sanded surface; bevelled | |

Custom Specifications available on request | edges available | |

Outstanding characteristics | Environmental friendly, 100% asbestos-free or 3%containing, outstanding fire resistance, high tensile and bending strength, remarkable moisture resistance, stable dimension, durable, excellent heat insulation and soundproofing, easy Installation | |

Main usage | Partitioning wall, ceiling tile | |

Other usage | Protecting wall system, movable floor, countertop, panel | |

billboard, kitchen and bathroom wall, | ||

pipeline insulation | ||

Physical property | Raw material | Tobermorite, cement, Quartz sand, fiber |

Density | 1.1-1.3 g/cm3 | |

Flexural strength | >13 Mpa; real test >15 Mpa (GB/T7019-1997) | |

Moisture content | <10%< span=""> | |

Fire rating test | Class A incombustible material (GB8624) | |

Soundproofing | 45-55 dB (GBJ75-84) | |

Thermal conductivity | ≤0.3W/MK (JC/T564) | |

Radiation | Accordance with standard (GB6566-2001) | |

Incombustibility | 4 h | |

Moisture movement | ≤0.25% (GB/T7019-1997) | |

Dry shrinking rate | <0.09%(GB/T7019-1997) | |

Application | Commercial, industrial, and apartment buildings

| |

Application:

partition & ceiling in office, supermarket, hotel, hospital, gymnasium, school, stations; interior wallboard in carriage, marine structure, shipping vessel which need fire-proof, heat insulation and damp-proof

Materials: Tobermorite, lime, Quartz sand, wood fiber

Fire-proof rate: A-class incombustible (GB8624-1997)

Incombustibility: 240 minutes (GB/T9978-1999)

Density: 1.2-1.4g/cm3

Moisture:<10%< span="">

Heat conduction: 0.24W/MK (Jc/t564) Average

Sound-absorption: 45db (GBJ75-84)

Anti-bend strength: >15MPa (GB/T7019-1997)

Moisture movement rate:<0.19% (GB/T7019-1997)

Installation:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the keels' vertical points and intensity.

(4) The metal stud with hole : one of our product is the special hole on C-stud every 600mm, which is easy for workers to install the electric lines and water tubes.

(5) Various sizes of metal track and metal stud : we are able to manufacture German,

(6) Factory direct sale price : We have our own factory to produce raw materials----galvanized(zinc coated) steel, as well as the product line, so we can provide you a lowest price.

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q:Wood fiber cement board | US rock cement board use

- Wood and cement board with cement and wood advantages: such as wood as light, flexible, good thermal insulation, construction convenience; such as cement-like solid, fire, moisture, mildew, anti-ants, show other plates are not unique Sex. Can be widely used in decorative interior and exterior walls, floors, ceilings, furniture, noise walls, elevated floor, to create a minimalist. Natural and full of Zen mood. This product also has the convenience of construction. Its surface is smooth, paint only once. And because the inner layer of wood particles, it is better to nail, you can use any woodworking tools.

- Q:Would you recommend putting crazy glue in the draft boards locks, or cement?

- this is funny...cement.

- Q:Gypsm plaster is recommended in Christopher Alexander's Pattern Language (#235 Soft Inside Walls) If I were to go to a building supply store and ask for gypsum plaster would they know what I was talking about? ...Is it a universal term? Can you give me a chemical formula?

- Gypsm is hydradated pulverized limestone. You would ask for Gypsym topcoat or Gypsm tape adhesive in the Drywall department of Lowes. It costs today $9.95 for a 5 gallon pail of the stuff. Gypsm is resoluable in water after drying. In other words you can redissolve gypsm in water. Gypsm is mined in the US in states like Michigan, Indiana, Ohio and so on. It is a naturally occuring substance. Plaster of Paris is unhydrated form of lime. When wetted with water it changes chemically and remains hard no matter if submerged into water. The process is irreversible. Cement is made from clay and limestone fired to high temperatures, then ground and pulverized. When water is added to cement it changes its chemistry and the water reacts with cement forming a new compound It is irreversible The Romans invented Cement. Common Drywall is gypsm between 2 layers of paper enclosure. There are also metal lath in 26x84 inch lenghts and plaster board lath in 16x36 inch lengths Those all above are nailed or glued to the house studs.

- Q:Hello, my husband and myself are remodeling our bathroom....here's the question... we removed hideous vinyle tiles and underneath is the cement floor with thin layer of black adhesive from the tiles....the floor is pretty sound except for a small crack in cement by the entry door.... should we fix the crack and tile over the cement? or thin set 1/4''cement fiber board to the floor and tile over that? and if we do use the fiber board is the thin set enough to hold it down? we can't really screw/nail it cuz subfloor is cement. Any help is appreciated! Thanks!

- I am assuming you are going with ceramic tile. If that is the case then you do not need fiberboard. Just tile right to the concrete floor. As for the crack either fill it in or use a product called RedGaurd. RedGaurd is a rubberized product that when applied over the crack will expand and contract and thus keep the crack covered. You can apply RedGaurd then put mortar right over it.

- Q:why is gypsum always interground with cement clinker during the final stages of portland cement manufacture?

- Because they are trying to dispose of Gypsum and this is one of the few ways that it can be blended with something else in large quantities. Gypsum is produced as a by-product form the de-sulphurisation of flue gasses from power plants that still burn dirty fuels like coal or oil residues. There is often thousands of tons of this stuff produced every day and it has to be dumped somewhere. Land fill sites are filling up rapidly and charge big fees for disposal so it is very attractivce to belnd it into cement products. Gypsum is also used as the main part of plaster board which is another place to get rid of the unwanted material.

- Q:What is the cement pressure plate, what is the use of it?

- Is a new generation of "green" building materials, in the excellent moisture, fire performance based on the unique environmental protection features. It is based on siliceous and calcareous materials as the main substrate, with cellulose fiber reinforced materials, mixed with other auxiliary materials, through the copy forming, high pressure curing the formation of a new type of building materials.

- Q:The tile guy that I am using has never worked with stone, so I am worried. Can you please give me some insight on some things I should know about using stone (slate) for wall tile in a shower/bath.

- You would use cement grout. If its in your house, i would consider then laquering it to make it nice and shiny and stop water sitting in cracks and creating mould.

- Q:How the cement pressure plate sticks on the brick

- Crack: tiles shop after 24 hours to clean up the hook, hook before the first floor of the gap should be wiped with impurities, with a special sealant joints. Clean up: in the home decoration tiles construction process with the dry with the clear, after the completion of (generally should be after 24h) and then cotton yarn and other objects on the surface of the brick. The quality of floor tiles: floor tile clean, clear pattern, consistent color, uniform seams, the surrounding straight, hook seam smooth, plate without cracks, angle and lack of shock phenomenon.

- Q:Use the cement board to do the bathroom partition, how to do waterproof, with which waterproof material is better

- Now the house decoration bathroom waterproof is generally not membrane waterproof, and the usual way is to use waterproof paint to do waterproof. Waterproof coating asphalt-based waterproof coating basically no, the two commonly used paint is: (1) synthetic polymer polyurethane waterproof coating (corner, etc. need to add polyester cloth, glass cloth, etc.) (2) polymer modified asphalt SBS waterproof coating (need to add carcass reinforcement polyester cloth, glass cloth, etc.).

- Q:Hi everybody! I just installed hardibacker boards in my bathroom. But I had to remove 1 pc 'coz I made a mistake. Can I still use it again? I screwed it every 8 inches around the edges and along every stud. Can I just cover the holes with thinset? Thanks!

- just fill in the holes, as you tileing anyways, the cement will cover, any cracks up

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Cement Board Water Proof Type with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 pc

- Supply Capability:

- 20000 pc/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords