Hot Rolled 1065 High Carbon Steel Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled 1065 High Carbon Steel Bars

Technical Paramenters

Description | 1065 steel rould bar | |

Material Range | ASTM /AISI | 1005,1006,1008,1010,1015,1020,1025,1030,1035, 1040,1045,1050,1055,1060,1065,1070,1080,1084 |

DIN | Ck10,Ck15,Ck22,Ck25,Ck30,Ck35,Ck40,Ck45,Ck50, 30Mn4,40Mn4 | |

Standard | GB/T799,ASTM A29,A36,A108,A321,A575,BS970,DIN1652,JIS G4051 | |

Section shape | Round Other shape such as square,hexagonal,flat,angle | |

Surface | Black, galvanized,grinded, | |

Specifications | Round bar | Diameter: 12mm~650mm |

Angle bar | Size: 3mm*20mm*20mm~12mm*800mm*800mm | |

Square/ bar | Size: 4mm*4mm~100mm*100mm | |

Flat bar | Thickness: 2mm~100mm | |

Width:10mm~500mm | ||

Hexagonal | Size: 4mm~800mm | |

Length | Standard 6m,9m,12m or as required. | |

Trade terms | Payment terms | T/T,L/C,Western Union |

Price terms | FOB,CIF,CFR,EXW | |

Applications | Steel round bar is widely used for all general fabrication and repairs in industrial maintenance, agricultural implements, transportation equipment, ornamental work frame work, braces, supports, shafts,axels,etc. Hot rolled Steel round bars have a slightly grain textured finish. | |

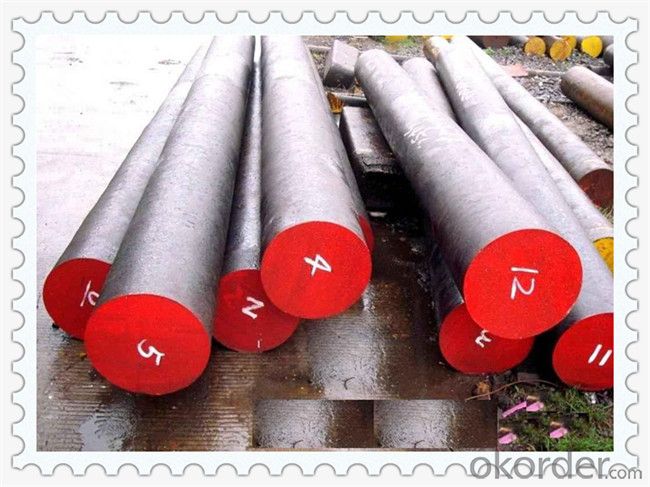

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: How are steel round bars used in the mining industry?

- Steel round bars are commonly used in the mining industry for various applications such as drilling, excavation, and support structures. These bars are used as drill bits, anchor bolts, and reinforcement elements in underground mines and open-pit mining operations. Their high strength and durability make them suitable for withstanding the harsh conditions and heavy loads encountered in mining activities. Additionally, steel round bars are also utilized in the construction of mining equipment and machinery for their ability to provide structural integrity and stability.

- Q: Can steel round bars be used in the automotive industry?

- Indeed, the automotive industry does make use of steel round bars. These bars are frequently employed in various capacities within the industry. Specifically, they are commonly utilized in the fabrication of different components, including axles, drive shafts, suspension parts, and steering components. The reason for their popularity lies in their exceptional attributes, such as high strength, durability, and resistance to wear and tear. These qualities enable them to withstand the rigorous conditions and heavy loads that automotive components are subjected to. Moreover, the ease with which steel round bars can be machined and welded facilitates efficient production and assembly processes in the automotive sector. Consequently, steel round bars are highly regarded as a dependable and cost-effective option for automotive manufacturers, making them a favored material in the industry.

- Q: What is the difference between a turned and a ground steel round bar?

- Two distinct types of steel bars, a turned steel round bar and a ground steel round bar, have undergone different manufacturing procedures. To create a turned steel round bar, a cylindrical steel rod is rotated against a cutting tool, which eliminates material from the bar's surface to achieve the desired dimensions and finish. This process enhances the bar's dimensional accuracy and smoothness. Turned steel round bars find common usage in precision machining or automotive components that necessitate tight tolerances and a smooth surface finish. Conversely, a ground steel round bar is manufactured by passing a turned steel round bar through a grinding machine. This machine uses an abrasive wheel to eliminate any surface imperfections or irregularities from the bar. The grinding process ensures that the bar maintains a consistent diameter and a smooth, polished surface. Ground steel round bars often find application in aerospace components or hydraulic cylinders that demand a high level of precision and surface finish. In conclusion, the primary distinction between a turned and a ground steel round bar lies in the manufacturing processes they undergo. While turned bars are created by cutting material from the surface, ground bars are refined by grinding to achieve superior dimensional accuracy and surface smoothness. The selection between turned and ground steel round bars is contingent upon the specific requirements of the application and the desired level of precision and surface finish.

- Q: Can steel round bars be used in the production of packaging equipment?

- Yes, steel round bars can be used in the production of packaging equipment. Steel round bars are commonly used in various industries due to their high strength and durability. In packaging equipment, steel round bars can be used to provide structural support, reinforcement, or as components in the machinery's moving parts. The steel's hardness and resistance to wear and tear make it suitable for handling heavy loads and continuous operation. Additionally, steel round bars can be easily machined, welded, and modified to meet the specific requirements of the packaging equipment. Overall, steel round bars are a reliable and commonly used material in the production of packaging equipment.

- Q: Are steel round bars suitable for the production of springs?

- Indeed, springs can be produced using steel round bars. Steel, renowned for its exceptional strength and durability, finds widespread application in spring manufacturing. The circular configuration of these bars facilitates effortless shaping and molding, rendering them an ideal choice for spring production procedures. Steel round bars can be conveniently machined and heat-treated to impart the desired spring attributes, including elasticity and resilience. Furthermore, steel boasts a remarkable tensile strength, enabling it to endure substantial loads. Consequently, it proves well-suited for applications necessitating robust and dependable springs.

- Q: Can steel round bars be annealed?

- Yes, steel round bars can be annealed. Annealing is a heat treatment process that involves heating the steel to a specific temperature and then gradually cooling it down. This process helps to relieve internal stresses, improve ductility, and enhance the material's machinability. Annealing can be applied to a wide range of steel products, including round bars, to make them softer, more workable, and reduce the risk of cracking or failure during subsequent manufacturing processes.

- Q: How are steel round bars measured?

- Steel round bars are typically measured by their diameter. The diameter is determined by measuring the distance across the widest point of the bar, usually in millimeters or inches. It is important to note that the diameter measurement is taken at the greatest cross-section of the round bar, which is the distance across the center point. This measurement is crucial for various applications as it helps determine the strength, stability, and load-bearing capacity of the steel round bar.

- Q: Can steel round bars be used for making tools?

- Steel round bars are a great choice for making tools. They are widely used in tool making because they are strong, durable, and versatile. The strength of steel allows it to withstand heavy use and provides stability to tools. Additionally, steel round bars can be easily machined and shaped into different tool designs, making it possible to create a variety of tools such as wrenches, chisels, punches, and hammers. Furthermore, steel's resistance to corrosion ensures that tools made from steel round bars will last longer. In conclusion, steel round bars are a popular option in tool making because they have excellent mechanical properties and can be used for many different purposes.

- Q: Can steel round bars be used in the manufacturing industry?

- Yes, steel round bars can be used in the manufacturing industry. Steel round bars are versatile and widely used in various manufacturing processes. They can be used for machining, forging, welding, and fabrication to create a wide range of products such as machinery parts, tools, automotive components, construction materials, and more. Steel round bars offer high strength, durability, and excellent resistance to wear, making them suitable for demanding manufacturing applications. Additionally, steel round bars are available in different grades and sizes, allowing manufacturers to choose the most suitable option for their specific requirements.

- Q: What is the typical hardness of a steel round bar?

- The typical hardness of a steel round bar can vary depending on the specific grade and composition of the steel. However, most steel round bars have a typical hardness ranging from 20 to 60 HRC (Rockwell Hardness Scale).

Send your message to us

Hot Rolled 1065 High Carbon Steel Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords