Hot Rolled Carbon Steel Round Bars S10C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

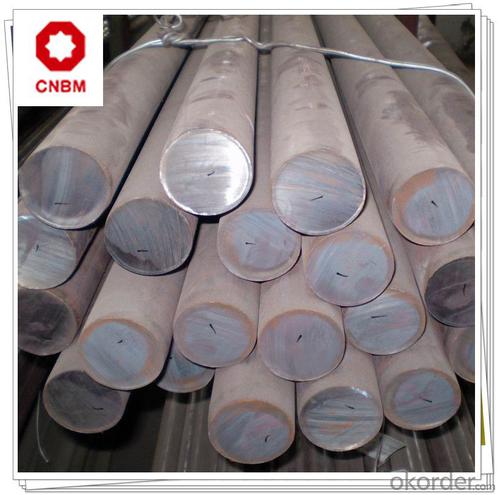

Hot Rolled Carbon Steel Round Bars S10C

Product Specification

1, Chemical Composition %

| Grade | C | Si | Mn | S | P | Cr | Ni | Cu |

| S10C | 0.08-0.13 | 0.15-0.35 | 0.30-0.60 | ≤0.030 | ≤0.030 | ≤0.20 | ≤0.25 | ≤0.25 |

2, Mechanical Properties

| Strength of Extension σb | Yield Strength σs | Reduction of Area ψ | Elogation δ5 | Hardness |

| ≥335(34) Mpa | ≥205(21) Mpa | ≥55% | ≥31% | ≤137HB |

3, Diameter: 16mm - 300mm

Length: Max 12m

Application

Can be used to manufacture weld assembly, cold stamping parts, forge pieces and carburized parts which do not require high strength such as bolts, washers, plate, shell, etc.

Product Main Points

1, Heat Treatment: normalizing, annealing, tempering, quenching

2, Surface Treatment: black, grinding, bright, polish

3, Product Process: hot rolled, cold drawn, forged

FAQ

1, Payment Terms:

30% T/T deposit & 70% T/T before delivery.

Irrevocable L/C at sight

2, Trade Terms:

EXW, FOB, CIF, CNF

3, Delivery Time:

Normally 30-40 days. According to quantity.

4, Manufacture or Trading Company:

CNBM is a state-owned fortune global 500 trading company. We have intergrated supply system.

There are about 20 overseas locations in different countries.

Product Show

Work Shop

About Us

- Q: What are the different international standards for steel round bars?

- There are several international standards that define the specifications and requirements for steel round bars. Some of the commonly used standards include: 1. ASTM A36/A36M: This standard covers carbon structural steel shapes, plates, and bars of structural quality for use in riveted, bolted, or welded construction of bridges and buildings. It specifies the chemical composition, mechanical properties, and dimensional tolerances for steel round bars. 2. ASTM A615/A615M: This standard specifies the requirements for deformed and plain carbon-steel bars for concrete reinforcement. It covers bars with sizes ranging from 6 to 60 mm in diameter and provides guidelines for chemical composition, mechanical properties, and bend tests. 3. BS 4449: This British Standard covers steel bars for the reinforcement of concrete. It outlines the requirements for carbon steel bars in various grades, including B500B and B500C. It specifies the tensile properties, chemical composition, and dimensional tolerances for these steel round bars. 4. DIN 17100: This German standard specifies the general structural steels, including steel round bars. It provides guidelines for the chemical composition, mechanical properties, and technical delivery conditions for different grades of steel bars. 5. JIS G3101: This Japanese Industrial Standard covers general structure rolled steel for various applications. It includes steel round bars and defines the chemical composition, mechanical properties, and dimensional tolerances for different grades of steel bars. 6. ISO 6935-2: This International Organization for Standardization standard specifies the requirements for hot-rolled steel bars for the reinforcement of concrete. It provides guidelines for the chemical composition, mechanical properties, and dimensional tolerances of steel round bars used in construction. These are just a few examples of the various international standards that exist for steel round bars. It is important to consult the appropriate standard based on the specific application and requirements to ensure compliance and quality of the steel round bars used.

- Q: What are the different surface defects that can be found in steel round bars?

- There are several surface defects that can be found in steel round bars. These defects can vary in severity and can have an impact on the overall quality and performance of the steel. Some common surface defects include: 1. Scale: Scale refers to the thin, flaky layer of iron oxide that forms on the surface of steel during the manufacturing process. It can appear as a rough, scaly texture and may cause issues with adhesion or coating application. 2. Pitting: Pitting is the formation of small holes or depressions on the surface of the steel. It can be caused by corrosion, contamination, or uneven heating during the manufacturing process. Pitting can weaken the structural integrity of the steel and increase the likelihood of failure. 3. Scratches: Scratches are superficial marks or cuts on the surface of the steel. They can occur during handling, transportation, or processing. While small scratches may not significantly affect the performance of the steel, deep or extensive scratches can create stress concentrations and reduce the strength of the material. 4. Cracks: Cracks are linear fractures that can occur on the surface of the steel. They can be caused by excessive cooling, improper heat treatment, or mechanical stress. Cracks can propagate and lead to catastrophic failure if not detected and addressed. 5. Decarburization: Decarburization is the loss of carbon content on the surface of the steel due to exposure to high temperatures or improper heat treatment. It can result in a softer and weaker surface layer, reducing the material's strength and hardness. 6. Laminations: Laminations are layers or separations within the steel round bar that can occur due to improper rolling or manufacturing processes. These can weaken the material and reduce its load-bearing capacity. 7. Inclusions: Inclusions are non-metallic impurities or foreign substances that are trapped within the steel during the manufacturing process. They can include oxides, sulfides, or other debris. Inclusions can act as stress concentrators and reduce the material's resistance to cracking and deformation. Detecting and addressing these surface defects is crucial to ensure the quality and reliability of steel round bars. Various inspection techniques such as visual examination, ultrasonic testing, magnetic particle testing, or dye penetrant testing can be employed to identify and assess the severity of these defects.

- Q: What are the different surface conditions for steel round bars?

- Steel round bars can come in a variety of surface conditions depending on their intended use and manufacturing process. Some common surface conditions for steel round bars include: 1. Hot Rolled: This is the most common surface condition for steel round bars. It is achieved by heating the steel above its recrystallization temperature and then rolling it through a series of hot rolling mills. This process gives the steel a rough surface with a scale layer that needs to be removed. 2. Cold Drawn: In this surface condition, the steel round bars are pulled through a die at room temperature, which results in a smoother and more precise surface finish. Cold drawn bars have improved dimensional accuracy and surface quality compared to hot rolled bars. 3. Peeled: Steel round bars can also be peeled to remove the scale layer and achieve a smooth surface finish. This process involves rotating the bar against a cutting tool, which results in a clean and bright surface. 4. Ground: Grinding is another method used to achieve a smooth surface finish on steel round bars. It involves removing material from the surface using abrasive belts or wheels, resulting in a precise and consistent surface. 5. Polished: Polishing is a surface treatment that further enhances the appearance and smoothness of steel round bars. It involves using abrasive compounds and buffing wheels to create a reflective and mirror-like finish. 6. Coated: Steel round bars can be coated with various materials to improve their corrosion resistance or enhance their appearance. Common coatings include zinc, chrome, nickel, and various types of paint. The choice of surface condition for steel round bars depends on the specific application and the desired properties. Each surface condition offers different advantages in terms of appearance, corrosion resistance, and mechanical properties.

- Q: How do you prevent scaling of steel round bars during heat treatment?

- To minimize scaling of steel round bars during heat treatment, various steps can be taken: 1. Employ a protective atmosphere: Heat treatment can be conducted in a controlled gas environment, such as a furnace with regulated gas composition. This shields the steel bars from oxygen exposure, the main cause of scaling. 2. Employ a protective coating: Coating the steel round bars with a substance like refractory material or a thin layer of paint can help prevent scaling. This creates a barrier between the steel and the oxygen in the atmosphere, reducing the likelihood of scaling. 3. Use a reducing atmosphere: Instead of a regular atmospheric environment, heat treatment can be carried out in a reducing atmosphere. This involves introducing gases like hydrogen or nitrogen into the furnace, reacting with oxygen to create a controlled environment that prevents scaling. 4. Control the heating rate: Rapid heating can lead to increased scaling due to sudden exposure to high temperatures. By controlling the heating rate, such as gradually increasing temperature, scaling can be minimized. 5. Limit the exposure time: Reducing the duration that steel round bars are exposed to high temperatures helps prevent scaling. This can be achieved by optimizing the heat treatment process and avoiding prolonged exposure to elevated temperatures. 6. Clean the surface before heat treatment: Before heat treatment, it is essential to remove any contaminants or residues from the surface of the steel round bars. This can be achieved through mechanical methods like wire brushing or chemical cleaning techniques, ensuring a clean surface that is less prone to scaling. Implementing these preventive measures effectively minimizes scaling of steel round bars during heat treatment, resulting in improved quality and performance of the treated bars.

- Q: Can steel round bars be galvanized?

- Indeed, it is possible to galvanize steel round bars. Galvanization is a technique that entails applying a protective zinc coating to the steel surface to prevent corrosion. This technique can be employed on various steel products, including round bars. By galvanizing steel round bars, not only is their resistance to corrosion enhanced, but also their durability and lifespan. The galvanization process entails immersing the round bars in a bath of molten zinc, which adheres to the steel and forms a protective layer. This layer serves as a barrier, safeguarding the steel from moisture, chemicals, and other corrosive elements. Consequently, galvanized steel round bars are extensively used in outdoor applications, such as construction, fencing, and marine environments, where they are exposed to harsh conditions.

- Q: How are steel round bars used in the construction of offshore structures?

- Due to their exceptional mechanical properties, steel round bars are widely employed in offshore construction for their robustness and resilience. These bars, typically crafted from carbon steel or alloy steel, are commonly utilized in the production of oil rigs, offshore platforms, pipelines, and subsea structures. The primary function of steel round bars in offshore construction is to furnish structural support and reinforcement. Particularly, they are instrumental in the creation of piles, which are lengthy cylindrical structures driven into the seabed to establish a stable foundation for offshore facilities. Steel round bars are preferred for this purpose due to their remarkable ability to endure the harsh marine environment and heavy loads. Additionally, offshore platforms, which serve as elevated workspaces for oil and gas exploration and production activities, heavily rely on steel round bars. These bars are employed to construct the framework of the platform, constituting vital structural elements such as columns, beams, and trusses. By welding or bolting them together, a robust and rigid structure capable of withstanding extreme weather conditions and substantial loads is created. Moreover, steel round bars are integral to the construction of pipelines, which enable the transportation of oil and gas from offshore wells to onshore facilities. These bars are utilized to fabricate pipeline supports, guaranteeing the stability and secure fastening of the pipeline to the seabed. To conclude, the significance of steel round bars in offshore construction cannot be overstated. Their exceptional strength, durability, and ability to withstand the demanding marine environment make them the ideal choice for providing structural support and reinforcement in offshore construction ventures.

- Q: How do you calculate the strength of a steel round bar?

- The strength of a steel round bar is typically calculated using the formula for tensile strength, which is the maximum amount of tensile stress that a material can withstand before breaking. This is determined by dividing the maximum load applied to the bar during a tensile test by its cross-sectional area.

- Q: How do you calculate the fatigue strength of a steel round bar?

- The fatigue strength of a steel round bar can be calculated using various methods, such as the stress-life (S-N) curve approach or the strain-life (ε-N) curve approach. 1. Stress-Life (S-N) Curve Approach: This method involves plotting the stress amplitude (S) against the number of cycles to failure (N) on a log-log scale. The S-N curve is obtained by subjecting multiple specimens of the steel round bar to different stress levels and measuring the number of cycles to failure for each stress level. The fatigue strength of the steel round bar can be determined by identifying the stress level at which the desired number of cycles to failure is achieved, typically referred to as the endurance limit. 2. Strain-Life (ε-N) Curve Approach: This method involves plotting the strain amplitude (ε) against the number of cycles to failure (N) on a log-log scale. Similar to the S-N curve approach, multiple specimens of the steel round bar are subjected to different strain levels, and the number of cycles to failure is measured. The strain-life curve can then be used to determine the fatigue strength by identifying the strain level corresponding to the desired number of cycles to failure. It is important to note that calculating the fatigue strength of a steel round bar requires conducting fatigue tests on representative specimens under controlled conditions. These tests involve subjecting the specimens to cyclic loading, typically in the form of tension-compression cycles, and recording the number of cycles to failure. The obtained data is then used to construct the S-N curve or the ε-N curve, which provides valuable information about the fatigue behavior and strength of the steel round bar.

- Q: How do you prevent corrosion on steel round bars?

- One way to prevent corrosion on steel round bars is by applying a protective coating, such as paint or a corrosion-resistant metal coating like zinc or epoxy. Regular maintenance, including cleaning and removing any dirt or moisture buildup, can also help prevent corrosion. Additionally, storing the steel round bars in a dry and controlled environment can minimize exposure to moisture and prevent corrosion.

- Q: How do steel round bars differ from steel square bars?

- The shape and appearance of steel round bars and steel square bars differ. Steel round bars have a circular cross-section and a cylindrical shape, making them suitable for applications that require strength and stability, such as construction, manufacturing, and engineering. Their circular shape allows for even distribution of stress and load, making them highly resistant to bending or twisting forces. They are commonly used as structural components in buildings, support beams, shafts, and axles. On the other hand, steel square bars have a square cross-section with four equal sides and sharp corners. This shape provides additional advantages in certain applications. Square bars offer better grip and handling due to their flat surfaces, making them easier to hold, stack, or secure during fabrication or installation. They are often utilized in the manufacturing of machinery, tools, frames, and brackets where square edges are necessary for precise alignment or stability. Both steel round bars and steel square bars are available in various grades and alloys, providing different levels of strength, hardness, and corrosion resistance. The choice between the two depends on the specific requirements of the project or application.

Send your message to us

Hot Rolled Carbon Steel Round Bars S10C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords