Carbon Structural Steel Round Bars ST37-2CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Structural Steel Round Bars ST37-2CR

Product Specification

1, Chemical Composition %

| Grade | C | Si | Mn | S | P | Cr |

| ST37-2CR | 0.21-0.25 | ≤0.35 | ≤1.4 | ≤0.045 | ≤0.045 | ≥0.30 |

2, Mechanical Properties

| Strength of Extension σb | Yield Strength σs | Impact AKv |

| 340-470 Mpa | ≥235 Mpa | ≥27J |

3, Diameter: 9mm - 80mm

Application

1, Widely used in construction and engineering structure.

2, Widely used in making reinforcing steel bar or building plant room rack, high voltage transmission tower, bridge, vehicle, boiler, vessel, ship, etc.

3, Widely used in manufacturing mechanical parts which are not required to be with high performance.

Product Main Points

1, Heat Treatment: normalizing, annealing, tempering, quenching

2, Surface Treatment: black, grinding, bright, polish

3, Product Process: hot rolled, cold drawn, forged

FAQ

1, Payment Terms:

30% T/T deposit & 70% T/T before delivery.

Irrevocable L/C at sight

2, Trade Terms:

EXW, FOB, CIF, CNF

3, Delivery Time:

Normally 30-40 days. According to quantity.

4, Manufacture or Trading Company:

CNBM is a state-owned fortune global 500 trading company. We have intergrated supply system.

There are about 20 overseas locations in different countries.

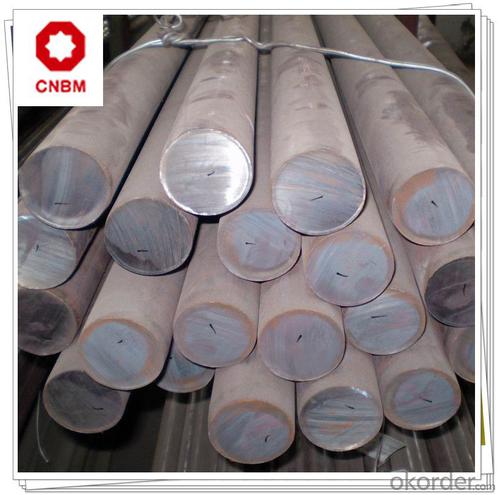

Product Show

Work Shop

About Us

- Q: What is the cost of steel round bars compared to other materials?

- The cost of steel round bars can vary depending on the specific type of steel and current market conditions. Generally, steel round bars tend to be more cost-effective compared to other materials such as aluminum or titanium, especially when considering their strength and durability. However, it is always recommended to compare prices and quality from different suppliers to get a more accurate understanding of the cost differences.

- Q: What are the typical hardness values for different grades of steel round bars?

- The typical hardness values for different grades of steel round bars can vary depending on the specific grade and manufacturing process. However, common ranges for hardness values in steel round bars can be between 200 and 400 on the Brinell hardness scale.

- Q: What are the standard sizes for steel round bars?

- The standard sizes for steel round bars vary depending on the specific industry and application. However, some common standard sizes include 1/4 inch, 3/8 inch, 1/2 inch, 5/8 inch, 3/4 inch, 7/8 inch, 1 inch, 1 1/4 inch, 1 1/2 inch, 1 3/4 inch, 2 inch, 2 1/2 inch, 3 inch, 3 1/2 inch, 4 inch, 4 1/2 inch, 5 inch, 5 1/2 inch, 6 inch, 7 inch, 8 inch, 9 inch, 10 inch, 11 inch, 12 inch, and so on. These sizes are commonly used in construction, manufacturing, and engineering industries, and they may vary slightly depending on the country or region. It is important to note that steel round bars can also be custom-made to specific sizes and lengths to meet the requirements of a particular project.

- Q: How do you determine the appropriate steel grade for a specific application?

- To determine the appropriate steel grade for a specific application, it is necessary to have a comprehensive understanding of the application's requirements and the properties of different steel grades. The following steps should be considered: 1. Begin by clearly defining the specific requirements of the application, such as load-bearing capacity, corrosion resistance, temperature resistance, and durability. Take into account factors such as the environment the steel will be exposed to, the expected stress levels, and any specialized characteristics needed. 2. Research the various steel grades available in the market once the application requirements are understood. Identify steel grades known for possessing the desired properties required for the specific application. Consult industry standards, expert opinions, and available resources to gain insights into different steel grades and their performance in similar applications. 3. Analyze the physical, mechanical, and chemical properties of the steel grades under consideration. Evaluate key properties such as strength, ductility, toughness, hardness, corrosion resistance, weldability, and formability. Compare these properties with the application requirements to determine which steel grades align best with the specific needs. 4. Evaluate the cost and availability of the steel grades that meet the application requirements. Take into account factors such as the initial cost, maintenance costs, and availability of the steel grade in the required form and quantity. This step ensures that the chosen steel grade is not only suitable but also feasible from an economic perspective. 5. Seek advice from experts, such as metallurgists or engineers, to gain valuable insights into selecting the appropriate steel grade. Their expertise and experience can help weigh the pros and cons of different steel grades, identify potential challenges, and suggest alternatives or modifications if necessary. 6. If feasible, conduct testing or trials using samples of the selected steel grade to assess its performance under real-world conditions. This step can help validate the suitability of the chosen steel grade and identify any unforeseen issues or areas for improvement. By carefully considering the application requirements, researching steel grades, evaluating material properties, considering cost and availability, seeking expert advice, and conducting testing and trials, one can effectively determine the appropriate steel grade for a specific application.

- Q: What is the difference between a rough turned and a centerless ground steel round bar?

- A rough turned steel round bar is a type of steel bar that has been partially machined to remove excess material and create a rough surface finish. It undergoes a turning process on a lathe, which removes the outer layer of the steel bar to achieve a specific diameter and shape. On the other hand, a centerless ground steel round bar is a type of steel bar that has undergone a precise grinding process to achieve a smooth and polished finish. This process involves feeding the steel bar through a centerless grinder, which removes any imperfections or irregularities on the outer surface, resulting in a consistently smooth and uniform diameter. In summary, the main difference between a rough turned and a centerless ground steel round bar lies in the level of surface finish and precision. Rough turned bars have a rougher surface finish and are not as precisely sized as centerless ground bars, which have a smooth, polished finish and are manufactured with tighter tolerances.

- Q: How do steel round bars compare to rubber round bars?

- Steel round bars and rubber round bars are two very different materials with distinct properties and applications. Steel round bars, made from hardened carbon steel, are known for their strength and durability. They have a high tensile strength and can withstand heavy loads and stress without deforming or breaking. Steel round bars are commonly used in construction, engineering, and manufacturing industries for structural support, reinforcement, and various mechanical applications. They are also highly resistant to heat and corrosion, making them suitable for applications in extreme conditions. On the other hand, rubber round bars are made from synthetic or natural rubber compounds. Rubber round bars offer unique advantages such as flexibility, elasticity, and vibration dampening properties. They are commonly used in applications where shock absorption, noise reduction, or sealing properties are required. Rubber round bars find applications in automotive industries, machinery mounts, conveyor systems, and various other industrial applications where their unique properties are beneficial. While steel round bars offer exceptional strength and rigidity, rubber round bars provide flexibility and vibration dampening capabilities. The choice between steel and rubber round bars primarily depends on the specific requirements of the application. If the application demands high strength and durability, steel round bars are the preferred choice. Conversely, if the application requires flexibility, elasticity, or vibration dampening, rubber round bars are more suitable. In summary, steel round bars and rubber round bars have different properties and applications. Steel round bars offer strength and durability, while rubber round bars provide flexibility and vibration dampening properties. The choice between the two depends on the specific requirements of the application.

- Q: What are the advantages of using nickel-zinc alloy steel round bars?

- There are several advantages of using nickel-zinc alloy steel round bars. Firstly, nickel-zinc alloy steel has a high strength-to-weight ratio, making it an excellent choice for applications where strength and durability are important. This allows for the construction of lighter structures without sacrificing strength or performance. Secondly, nickel-zinc alloy steel round bars have superior corrosion resistance compared to other types of steel. This makes them ideal for use in harsh environments where exposure to moisture, chemicals, or extreme temperatures may occur. The corrosion resistance properties of nickel-zinc alloy steel also contribute to its longevity and ability to withstand the test of time. Additionally, nickel-zinc alloy steel has excellent weldability and machinability, making it easy to work with and manipulate into various shapes and forms. This versatility allows for the creation of complex designs and structures, making it a popular choice in the construction and manufacturing industries. Furthermore, nickel-zinc alloy steel round bars have good thermal and electrical conductivity properties. This makes them suitable for applications that require the efficient transfer of heat or electricity, such as in the production of electrical components or heat exchangers. Lastly, nickel-zinc alloy steel is known for its high resistance to fatigue and wear, making it suitable for applications that involve repetitive or high-stress operations. This ensures that structures or components made from nickel-zinc alloy steel will maintain their performance and integrity over an extended period of time. In summary, the advantages of using nickel-zinc alloy steel round bars include high strength-to-weight ratio, superior corrosion resistance, excellent weldability and machinability, good thermal and electrical conductivity, and high resistance to fatigue and wear. These properties make nickel-zinc alloy steel a reliable and versatile material for a wide range of applications.

- Q: How do you calculate the moment of inertia of a steel round bar?

- In order to determine the moment of inertia for a steel round bar, one must possess knowledge of the bar's dimensions and properties. The moment of inertia serves as a gauge for an object's resistance to rotational changes. The formula utilized to compute the moment of inertia for a solid cylindrical item, such as a round bar, is as follows: I = (π/4) * D^4, where I signifies the moment of inertia and D symbolizes the bar's diameter. Initially, ascertain the diameter of the steel round bar by means of a caliper or ruler. It is essential to measure the diameter at its broadest point, typically found at the center. Subsequently, input the measured diameter into the formula and calculate the moment of inertia. It is crucial to use the correct units for diameter, such as inches or millimeters, to maintain consistency with the formula. For instance, let's assume the diameter of the steel round bar measures 2 inches. By substituting this value into the formula: I = (π/4) * (2 inches)^4 = (π/4) * 16 inches^4 = 4π inches^4. Therefore, the moment of inertia for the steel round bar with a diameter of 2 inches equals 4π inches^4. It is imperative to recognize that this formula assumes a solid cylindrical shape devoid of any alterations in diameter or hollow sections. If the round bar presents variations in diameter or is hollow, the moment of inertia calculation becomes more intricate and necessitates additional considerations.

- Q: Are steel round bars used in the automotive industry?

- Yes, steel round bars are commonly used in the automotive industry. They are utilized in various applications such as the manufacturing of engine components, suspension systems, chassis, and axles. Steel round bars offer superior strength, durability, and versatility, making them an ideal choice for automotive parts that require high performance and reliability. Additionally, steel's ability to withstand heavy loads and resist deformation makes it suitable for use in critical automotive applications where safety is paramount.

- Q: Can steel round bars be used for making suspension springs?

- Certainly! Suspension springs can indeed be made using steel round bars. The reason steel is often chosen as the material for suspension springs is because of its exceptional strength and durability. By forging or shaping the round bars into the desired spring shape, and subsequently subjecting them to heat treatment, the desired spring characteristics can be achieved. Moreover, steel round bars can be effortlessly machined and drilled to accommodate various suspension systems and components. Nevertheless, it is crucial to carefully consider the specific requirements and load capacity of the suspension system, in order to ensure that the selected steel round bars are appropriate for the intended application.

Send your message to us

Carbon Structural Steel Round Bars ST37-2CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords