Carbon Structural Steel Round Bars SAE1018CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Structural Steel Round Bars SAE1018CR

PRODUCT USE

Carbon steel applies to chemical industry, shipping industry,manufacturing industry, construction, decorate industry, electric power, pump shafts, sanitary wares, furniture handles, boiler, high temperature resistant, low temperature resistant, corrosion resistant.

PRODUCT MAIN POINTS

1, Heat Treatment: normalizing, annealing, tempering, quenching

2, Surface Treatment: black, grinding, bright, polish

3, Product Process: hot rolled, cold drawn, forged

FAQ

1, Payment Terms:

30% T/T deposit & 70% T/T before delivery.

Irrevocable L/C at sight

2, Trade Terms:

FOB, CIF, CNF

3, Delivery Time:

Normally 30-40 days. According to quantity.

4, Manufacture or Trading Company:

CNBM is a state-owned fortune global 500 trading company. We have intergrated supply system.

There are about 20 overseas locations in different countries.

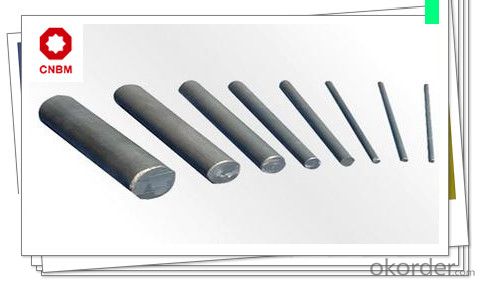

PRODUCT SHOW

PRODUCT SPECIFICATION

1, Chemical Composition %

| Grade | C | Si | Mn | S | P | Cr | Ni | Cu |

| SAE1020CR | 0.15-0.20 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.25 |

2, Mechanical Properties

| Strength of Extension σb | Yield Strength σs | Elogation δ5 | Reduction of Area ψ | Hardness (no heat treatment) |

| ≥410(42) Mpa | ≥245(25) Mpa | ≥25 % | ≥55 % | ≤156HB |

ABOUT US

- Q: Can steel round bars be used in outdoor applications?

- Yes, steel round bars can be used in outdoor applications. Steel is a durable and corrosion-resistant material, making it suitable for various outdoor environments. However, it is essential to choose the right type of steel and apply appropriate protective coatings to ensure long-term performance and prevent rusting.

- Q: What are the advantages of using nickel-alloy steel round bars?

- Nickel-alloy steel round bars offer numerous benefits: 1. Superior strength and durability: Renowned for their exceptional strength and durability, nickel-alloy steel round bars can endure high levels of stress and boast excellent corrosion resistance. Consequently, they are ideal for use in demanding environments. 2. Impressive temperature resistance: With their remarkable temperature resistance properties, nickel-alloy steel round bars retain their strength and integrity even in elevated temperatures. This renders them suitable for applications in industries such as aerospace, power generation, and petrochemicals. 3. Exceptional corrosion resistance: Nickel-alloy steel round bars exhibit outstanding resistance to rust and oxidation, making them highly resistant to corrosion. This quality makes them perfect for deployment in marine environments, chemical plants, and other settings where exposure to corrosive substances is common. 4. Excellent mechanical properties: Boasting outstanding mechanical properties like high tensile strength, toughness, and ductility, nickel-alloy steel round bars can withstand heavy loads and impacts without deformation or failure. As a result, they prove suitable for use in critical structural applications. 5. Versatility and adaptability: Nickel-alloy steel round bars are easily machinable, forgeable, and weldable, offering increased versatility in manufacturing processes. They can be shaped and formed into various sizes and dimensions to meet specific requirements, making them highly adaptable to different industries. 6. Cost-effective solution: Despite their initial higher cost compared to other materials, nickel-alloy steel round bars prove to be a cost-effective choice in the long run. Their resistance to corrosion and wear minimizes maintenance and replacement expenses, resulting in significant cost savings over time. In conclusion, the advantages of nickel-alloy steel round bars lie in their superior strength, impressive temperature resistance, exceptional corrosion resistance, excellent mechanical properties, versatility, adaptability, and cost-effectiveness. These qualities establish them as reliable and efficient options for numerous applications across various industries.

- Q: What is the difference between a smooth and a deformed steel round bar?

- A smooth steel round bar is characterized by its consistently even surface, free from any visible imperfections or deformities. It is typically produced using the hot rolling technique, which involves heating a steel billet and passing it through a series of rolling mills to achieve the desired shape and surface finish. Smooth steel round bars are commonly employed in applications where aesthetics and surface quality are of utmost importance, such as architectural designs or decorative metalwork. Contrarily, a deformed steel round bar possesses intentional deformations or patterns on its surface. These deformations can take various forms, including ridges, ribs, or indentations. The purpose of incorporating deformations on the surface of a steel round bar is to enhance its ability to bond with concrete or other materials. The irregular surface of a deformed bar provides increased friction and better adhesion, thereby improving the structural integrity of reinforced concrete structures. Deformed steel round bars find primary use in construction projects, particularly in reinforced concrete structures like columns, beams, and slabs. The deformations on the bar's surface serve to prevent slippage between the steel and concrete, ensuring a stronger bond and enhancing the overall stability and durability of the structure. To summarize, the key distinction between a smooth and a deformed steel round bar lies in their surface characteristics and intended applications. Smooth bars possess a uniform and smooth surface, making them suitable for applications that prioritize aesthetics and surface quality. Deformed bars, on the other hand, possess intentional deformations to enhance bonding with concrete, making them well-suited for construction projects that require reinforced concrete structures.

- Q: Can steel round bars be heat treated to improve their mechanical properties?

- Yes, steel round bars can be heat treated to improve their mechanical properties. Heat treatment is a process that involves heating the steel to a specific temperature, holding it at that temperature for a certain period of time, and then cooling it rapidly or slowly. This process can alter the microstructure of the steel, resulting in changes to its hardness, strength, toughness, and other mechanical properties. There are several types of heat treatment processes that can be used on steel round bars, depending on the desired outcome. For example, annealing is a heat treatment process that involves heating the steel to a specific temperature and then slowly cooling it. This process helps to relieve internal stresses in the steel, improve its ductility, and make it easier to machine. Another common heat treatment process is quenching and tempering. This involves heating the steel to a specific temperature and then rapidly cooling it, usually by immersing it in a quenching medium such as oil or water. This rapid cooling process helps to harden the steel, making it stronger and more resistant to wear and abrasion. After quenching, the steel is often tempered by reheating it to a lower temperature, which helps to reduce its brittleness and improve its toughness. In addition to annealing and quenching and tempering, other heat treatment processes such as normalizing, case hardening, and precipitation hardening can also be used to improve the mechanical properties of steel round bars. These processes involve different heating and cooling techniques, and are used to achieve specific outcomes based on the desired properties of the steel. Overall, heat treatment is a versatile and effective method for improving the mechanical properties of steel round bars. By carefully controlling the heating and cooling process, it is possible to achieve significant improvements in hardness, strength, toughness, and other properties, making the steel suitable for a wide range of applications.

- Q: Can steel round bars be used in the fabrication of machinery?

- Yes, steel round bars can definitely be used in the fabrication of machinery. Steel round bars are commonly used in the manufacturing industry for various applications, including the fabrication of machinery and equipment. They possess several desirable properties that make them suitable for this purpose. Firstly, steel round bars offer excellent strength and durability. They are known for their high tensile strength, which means they can withstand heavy loads and resist deformation. This strength is crucial in machinery fabrication, as the components of machinery need to be able to endure the stresses and forces that they will be subjected to during operation. Additionally, steel round bars have good machinability, which means they can be easily shaped and formed into the desired components for machinery. This makes them highly versatile and allows for the creation of complex and intricate machine parts. Furthermore, steel round bars have good resistance to corrosion and wear, which is essential in machinery fabrication. Machinery often operates in harsh environments or comes into contact with various substances, such as chemicals, oils, or abrasive materials. The corrosion and wear resistance of steel round bars ensure that the fabricated machinery can withstand these conditions and maintain its performance over time. Lastly, steel round bars are readily available and cost-effective. They can be easily sourced from suppliers and manufacturers, making them a practical and economical choice for machinery fabrication. Overall, steel round bars are a popular and reliable material for the fabrication of machinery. Their strength, machinability, resistance to corrosion and wear, and availability make them an ideal choice for creating durable and high-performing machine components.

- Q: Can steel round bars be used in the manufacturing of marine propellers?

- Indeed, the utilization of steel round bars is applicable in the production of marine propellers. Given its robustness, endurance, and ability to resist corrosion, steel stands as a frequently employed substance within the marine sector. By shaping and machining steel round bars, one can obtain propellers that possess the requisite strength and stability essential for marine purposes. Moreover, steel is capable of enduring the harsh conditions prevalent in saltwater environments, thereby rendering it suitable for implementation in marine propellers.

- Q: Can steel round bars be used in structural applications?

- Steel round bars are suitable for structural applications and commonly utilized in construction and engineering projects that prioritize strength and durability. They offer versatility and can function as beams, columns, and supports for various structural elements. Thanks to their exceptional mechanical properties, such as high tensile strength and good ductility, they can withstand heavy loads and resist deformation effectively. Moreover, their easy joinability to other structural components contributes to their popularity within the construction industry.

- Q: How do steel round bars compare to plastic or composite bars?

- Plastic or composite bars cannot match the advantages of steel round bars. Firstly, steel round bars surpass plastic or composite bars in terms of strength and sturdiness. They excel in enduring heavy loads and providing outstanding structural support. Therefore, they are ideal for construction or engineering projects demanding robustness and durability. Secondly, steel round bars exhibit remarkable resistance to impact and wear. They can withstand severe environmental conditions and are less prone to cracking, chipping, or breaking compared to plastic or composite bars. Consequently, steel round bars suit heavy-duty applications where abrasion resistance is crucial. Moreover, steel round bars boast superior heat resistance in comparison to plastic or composite bars. They can endure high temperatures without distorting or compromising their structural integrity. Hence, steel round bars are suitable for applications involving extreme heat, such as machinery or equipment manufacturing. Furthermore, steel round bars are highly versatile and can be easily machined or modified to meet specific requirements. They allow for effortless customization and adaptability through cutting, drilling, bending, or welding. Conversely, plastic or composite bars may have limitations regarding customization or modification. Nonetheless, it is important to consider that steel round bars also have drawbacks when compared to plastic or composite bars. Steel is heavier, which can pose challenges in handling and transportation. Additionally, depending on the specific grade and quality, steel round bars can be more expensive than their plastic or composite counterparts. In conclusion, steel round bars surpass plastic or composite bars in terms of strength, durability, impact resistance, and heat resistance. Although they may have some drawbacks such as weight and cost, their overall performance and versatility make them the preferred choice for numerous high-performance applications.

- Q: What is the maximum diameter of a steel round bar?

- The maximum diameter of a steel round bar can vary depending on the specific grade and type of steel being used. However, in general, the maximum diameter of a steel round bar typically ranges from 1 inch to 12 inches. Larger diameters may be available on a custom order basis. It is important to consult the manufacturer or supplier for specific information regarding the maximum diameter of a steel round bar for a particular grade and type of steel.

- Q: What is the maximum copper content allowed for steel round bars?

- The permissible copper content in steel round bars varies depending on the grade and industry standards. Generally, copper is regarded as an alloying element in steel and is usually added in small quantities to improve specific properties. For most steel round bars, the maximum acceptable copper content typically ranges from 0.50% to 1.00%. However, it is crucial to consider that this may differ based on the application and grade of steel utilized. To determine the maximum allowable copper content, it is advisable to refer to the applicable industry standards or specifications for the specific steel grade and application.

Send your message to us

Carbon Structural Steel Round Bars SAE1018CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords