Carbon Structural Steel Square Bars SAE1018CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Structural Steel Square Bars SAE1018CR

Product Specifiction

1, Chemical Composition %

| Grade | C | Si | Mn | S | P | Cr | Ni | Cu |

| SAE1020CR | 0.15-0.20 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.25 |

2, Mechanical Properties

| Strength of Extension σb | Yield Strength σs | Elogation δ5 | Reduction of Area ψ | Hardness |

| ≥410(42) Mpa | ≥245(25) Mpa | ≥25 % | ≥55 % | ≤156HB |

Application

Carbon steel applies to chemical industry, shipping industry,manufacturing industry, construction, decorate industry, electric power, pump shafts, sanitary wares, furniture handles, boiler, high temperature resistant, low temperature resistant, corrosion resistant.

Product Main Points

1, Heat Treatment: normalizing, annealing, tempering, quenching

2, Surface Treatment: black, grinding, bright, polish

3, Product Process: hot rolled, cold drawn, forged

FAQ

1, Payment Terms:

30% T/T deposit & 70% T/T before delivery.

Irrevocable L/C at sight

2, Trade Terms:

EXW, FOB, CIF, CNF

3, Delivery Time:

Normally 30-40 days. According to quantity.

4, Manufacture or Trading Company:

CNBM is a state-owned fortune global 500 trading company. We have intergrated supply system.

There are about 20 overseas locations in different countries.

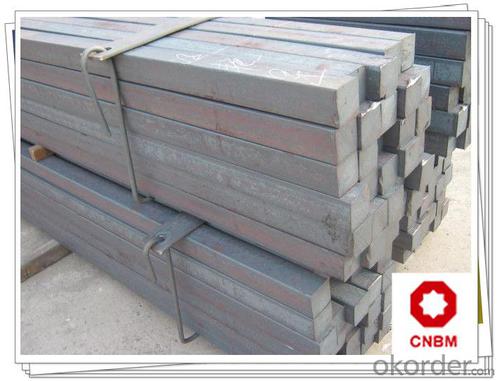

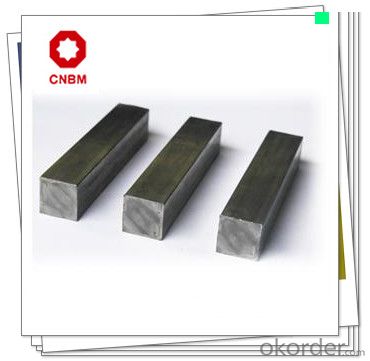

Product Show

Work Shop

About Us

- Q: What are the advantages of using magnesium-alloy steel round bars?

- Using magnesium-alloy steel round bars offers several benefits: 1. They are lightweight, making them ideal for industries that require weight reduction, such as aerospace and automotive. 2. Despite being lightweight, they have a high strength-to-weight ratio, ensuring structural integrity under high loads. 3. They have excellent corrosion resistance, making them suitable for outdoor and marine applications. 4. They are known for their superior machinability, allowing for precise and complex component manufacturing. 5. They effectively dissipate heat, making them ideal for applications that require heat management. 6. They contribute to a more sustainable and environmentally friendly manufacturing process due to magnesium's recyclability. 7. While they may have a higher initial cost, their lightweight nature leads to cost savings in transportation and installation. Additionally, their corrosion resistance and durability reduce long-term maintenance and replacement costs. In conclusion, magnesium-alloy steel round bars offer advantages such as lightweight, high strength-to-weight ratio, corrosion resistance, machinability, heat dissipation, eco-friendliness, and cost-effectiveness. They are highly desirable for industries that prioritize weight reduction, performance, and durability.

- Q: What are the different safety considerations when working with steel round bars?

- When working with steel round bars, there are several safety considerations to keep in mind. First and foremost, it is important to wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots to protect against potential hazards. Additionally, one should always handle the steel bars with care to avoid injuries from sharp edges or heavy lifting. It is crucial to ensure a secure and stable work area to prevent slips, trips, and falls. Furthermore, when using tools or machinery to cut or shape the steel bars, proper training and caution should be exercised to prevent accidents and follow all recommended safety procedures.

- Q: What is the tolerance level for steel round bars?

- The tolerance level for steel round bars can vary depending on the specific industry standards and requirements, but commonly, it falls within a range of +/- a few millimeters or less.

- Q: Are steel round bars suitable for electrical applications?

- Depending on specific requirements and conditions, steel round bars may be a suitable choice for electrical applications. Steel is well-known for its excellent conductivity, strength, and durability, making it a popular option for various electrical uses. However, before using steel round bars in electrical applications, it is crucial to take into account several factors. Firstly, while steel is a decent conductor, it is not as efficient as materials like copper or aluminum. Therefore, utilizing steel in electrical applications may lead to higher resistance and energy loss compared to these more conductive alternatives. Moreover, steel round bars might be susceptible to corrosion, particularly in humid or corrosive environments. This corrosion can significantly impact the overall performance and lifespan of the electrical system. To mitigate this issue, proper insulation or protective coatings may be necessary to prevent corrosion and ensure the reliability of the electrical application. To summarize, although steel round bars possess conductivity, strength, and durability that make them suitable for electrical applications, it is crucial to consider factors such as conductivity, corrosion resistance, and overall system requirements before employing them.

- Q: Can steel round bars be used for making bicycle frames or handlebars?

- Yes, steel round bars can be used for making bicycle frames or handlebars. Steel is a commonly used material in the manufacturing of bicycle frames and handlebars due to its strength, durability, and ability to absorb vibrations. Steel round bars provide the necessary structural integrity and rigidity required for these components, making them suitable for use in bicycle frames and handlebars.

- Q: The 8 thread can replace the beam stirrups by steel

- That's fine, but it's not necessary. It's more expensive. Of course, there's no substitute for steel bars on the site.

- Q: How are steel round bars classified based on their shape?

- Steel round bars are classified based on their shape into two main categories: hot-rolled round bars and cold-drawn round bars. Hot-rolled round bars are made by heating a steel billet until it becomes malleable and then passing it through a series of rollers to achieve the desired shape. This process results in a rougher surface texture and a slightly larger diameter compared to cold-drawn round bars. Hot-rolled round bars are commonly used in construction, engineering, and manufacturing applications where strength and durability are important. On the other hand, cold-drawn round bars are made by pulling a hot-rolled round bar through a series of dies at room temperature. This process improves the dimensional accuracy, surface finish, and mechanical properties of the steel. Cold-drawn round bars have a smoother surface texture and a more precise diameter, making them suitable for applications that require tight tolerances, such as precision machining, automotive components, and shafts for machinery. In summary, the classification of steel round bars based on their shape is determined by the manufacturing process used. Hot-rolled round bars are rougher and slightly larger in diameter, while cold-drawn round bars have a smoother surface texture and more precise dimensions. The choice between these two categories depends on the specific requirements of the application.

- Q: Can steel round bars be used in high-temperature applications?

- Yes, steel round bars can be used in high-temperature applications. Steel is known for its strength and durability, and it can withstand high temperatures without deformation or loss of structural integrity. However, the specific type of steel and its composition will determine its suitability for high-temperature applications. Stainless steel, for example, has excellent heat resistance and can be used in a wide range of high-temperature environments. Additionally, certain alloy steels are specifically designed for use in high-temperature applications, such as those found in the aerospace or petrochemical industries. It is important to consult with experts and consider the specific requirements of the application to ensure the appropriate steel round bars are chosen for high-temperature conditions.

- Q: Can steel round bars be used for making crankshafts?

- Yes, steel round bars can be used for making crankshafts. Crankshafts are important components in engines that convert the reciprocating motion of the pistons into rotational motion. Steel is a preferred material for crankshafts due to its high strength, durability, and ability to withstand the stress and load generated during engine operation. Steel round bars are often used for making crankshafts as they provide a solid and reliable foundation for the rotating assembly. The round shape of the bars allows for easy machining and shaping into the desired crankshaft design. Additionally, steel can be heat-treated to further enhance its mechanical properties, such as hardness and fatigue resistance, making it ideal for the demanding conditions and high-performance requirements of crankshafts in various engine applications.

- Q: Are steel round bars suitable for marine propeller applications?

- Yes, steel round bars are suitable for marine propeller applications. Steel is a widely used material in marine engineering due to its high strength, durability, and corrosion resistance. Steel round bars provide the necessary strength and stiffness required for propeller applications, ensuring efficient propulsion and withstanding the harsh conditions of marine environments.

Send your message to us

Carbon Structural Steel Square Bars SAE1018CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords