18 Gauge Stainless Steel

18 Gauge Stainless Steel Related Searches

18ga Stainless Steel 18/8 Stainless Steel 18 8 Stainless Steel 18 0 Stainless Steel 18/0 Stainless Steel Stainless Steel 18/8 16 Gauge Stainless Steel Stainless Steel 18 8 Stainless Steel 18 0 18-8 Stainless Steel 18/10 Stainless Steel 12 Gauge Stainless Steel Stainless Steel 18-8 18 Gauge Galvanized Sheet Metal 20 Gauge Stainless Steel Stainless Steel 18 10 Stainless Steel 18/10 18 10 Stainless Steel 8-18 Stainless Steel Stainless Steel Gauge 18-10 Stainless Steel 16 Gauge Stainless Steel Wire Stainless Steel Gauges Stainless Steel 16 Gauge Wire Cromova 18 Stainless Steel 318 Stainless Steel 14 Gauge Stainless Steel Wire 1810 Stainless Steel 18 8 Stainless Steel Properties 16 Gauge Stainless Steel Sheet18 Gauge Stainless Steel Supplier & Manufacturer from China

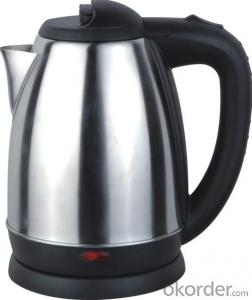

18 Gauge Stainless Steel refers to a specific thickness and quality of stainless steel, which is widely recognized for its durability, corrosion resistance, and strength. This type of stainless steel is commonly used in various industries, including construction, automotive, and food processing, due to its ability to withstand harsh conditions and maintain its integrity over time. The versatility of 18 Gauge Stainless Steel makes it a popular choice for a wide range of applications, from decorative elements to structural components.In terms of usage, 18 Gauge Stainless Steel is often employed in the manufacturing of kitchen appliances, architectural features, and industrial equipment. Its resistance to rust and staining, along with its ability to maintain a polished appearance, makes it an ideal material for both functional and aesthetic purposes. Whether it's used for creating durable countertops, constructing robust shelving systems, or fabricating intricate decorative pieces, 18 Gauge Stainless Steel consistently delivers on its promise of quality and longevity.

Okorder.com is a leading wholesale supplier of 18 Gauge Stainless Steel, boasting a vast inventory that caters to the diverse needs of customers across different industries. With a commitment to providing high-quality products at competitive prices, Okorder.com ensures that businesses have access to the materials they require to create durable and visually appealing products. By offering a comprehensive range of 18 Gauge Stainless Steel options, Okorder.com supports the growth and success of businesses that rely on this versatile material for their operations.

Hot Products