Carbon Steel Welding Wires Electrodes Carbon

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

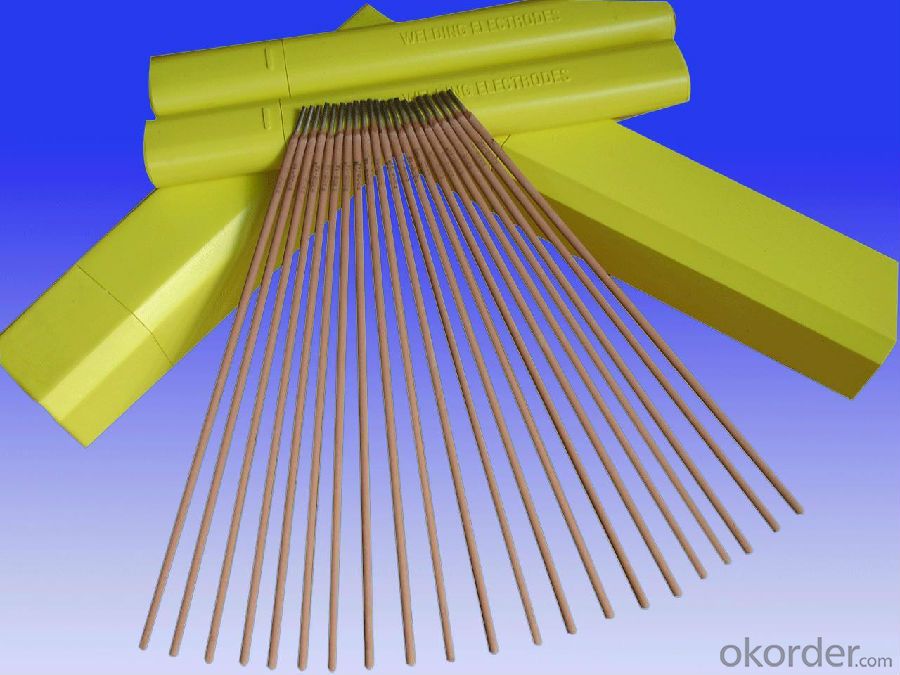

Structure of Carbon Steel Welding Wire Electrodes

1) Specially for Vertical-down welding

2) Perfect welding performance.

3)Operating current: 2.5MM:30-50,32.MM:70-100,4.0MM:90-140, 5.0MM: 150-200

4)Diameter:2.5mm-5.0mm

5)Material:Carbon Steel

6)Length:300-400mm

7)Delivery Time: 15-30 days after receiving L/C or pre-paid

Main Feature of Carbon Steel Welding Wire Electorde

Detail Package:All products will be standard export package, will be wooden boxes or bundled by steel strips, or as per customer's requirement

steel wire is a high cellulose potassium type welding rod for mild steel.

It is suitable for vertical -down welding and lap welding for sheet structures.

Such as smoke pipes, wind pipes ,oil tanks of teansformer, outside cover of vehicles.

FAQ

Why should you choose us?

Chose happens because of quality, then price, we can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents),

Quick goods delivery, our factories locate near the seaport, which is very convenient for transportation.

Datas Information of Carbon Steel Welding Wire Electorde

Chemical Composition of Deposited Metal(%)

| C | Mn | Si | S | p | Ni | Cr | Mo | V |

| ≤0.2 | ≤1.2 | ≤1.0 | ≤0.035 | ≤0.040 | ≤0.3 | ≤0.2 | ≤0.3 | less than 0.08 |

Pictures:

- Q: Can stainless steel wire be used for electrical resistors?

- Yes, stainless steel wire can be used for electrical resistors. Stainless steel has a high resistance to electrical current flow, making it suitable for use as a resistor material in various applications.

- Q: How are stainless steel wire shelves used in commercial kitchens?

- Stainless steel wire shelves are widely used in commercial kitchens for a variety of purposes. These shelves are designed to provide durability, cleanliness, and organization to the kitchen space. One of the primary uses of stainless steel wire shelves is for storage. These shelves are ideal for storing ingredients, utensils, and equipment as they are resistant to corrosion, easy to clean, and can withstand heavy loads. They can be used to store dry goods, canned supplies, pots and pans, small appliances, and more. Furthermore, stainless steel wire shelves are commonly used for organizing and displaying food items. In commercial kitchens, it is crucial to have a well-organized space that allows for easy access to ingredients and supplies. These shelves can be used to showcase fresh produce, spices, condiments, and other commonly used items, making them easily accessible to the kitchen staff. In addition to storage and organization, stainless steel wire shelves are also used for food preparation. These shelves can be placed near workstations, allowing chefs and cooks to have quick access to essential ingredients and tools while preparing dishes. They can hold cutting boards, mixing bowls, measuring cups, and other frequently used items, ensuring an efficient and streamlined workflow in the kitchen. Moreover, the open design of stainless steel wire shelves enables proper air circulation, preventing the accumulation of dust, dirt, and moisture. This feature is especially important in commercial kitchens, where cleanliness and hygiene are of utmost importance. The wire construction also allows for easy visibility, making it easier to locate specific items quickly. The versatility of stainless steel wire shelves makes them an essential component in commercial kitchens. They can be easily adjusted, mounted, or stacked, allowing for customization based on the unique needs and layout of the kitchen space. Additionally, their stainless steel construction makes them resistant to heat, chemicals, and stains, ensuring their longevity and reliability in a demanding kitchen environment. Overall, stainless steel wire shelves are indispensable in commercial kitchens for their durability, cleanliness, organization, and versatility. They provide an efficient storage solution, aid in food preparation, and contribute to the overall cleanliness and functionality of the kitchen space.

- Q: Does stainless steel wire have any magnetic properties?

- Yes, stainless steel wire does have magnetic properties. However, the amount of magnetism it exhibits depends on its composition and grade. Some stainless steel alloys are non-magnetic, while others may be slightly magnetic.

- Q: How to distinguish between 302 stainless steel screws and 304 stainless steel screws?

- [difference] 302 stainless steel and 304 stainless steel 304 stainless steel is one of the most widely used kind of chromium - nickel stainless steel, as a widely used steel, corrosion resistance, good heat resistance, low temperature strength and mechanical properties; punching, bending and other thermal processing, non hardening heat treatment (using temperature -196 to 800 DEG C). 302 stainless steel the carbon is relatively high (302 C = 0.15%; 304 C is less than or equal to 0.08%) and better strength. The other indicators are basically the same as those of 304.

- Q: Can stainless steel wire be used for electrical grounding?

- Yes, stainless steel wire can be used for electrical grounding. Stainless steel is a highly conductive material that provides a reliable pathway for electrical current to flow into the ground, making it suitable for grounding applications. Its resistance to corrosion and durability also make it a popular choice for this purpose.

- Q: Is stainless steel wire suitable for medical applications?

- Yes, stainless steel wire is suitable for medical applications. It has many desirable properties that make it an excellent choice for use in the medical field. Stainless steel is highly resistant to corrosion, which is crucial in medical environments where the wire may come in contact with bodily fluids or sterilization processes. Additionally, stainless steel wire is known for its high strength and durability, making it ideal for medical applications that require a strong and reliable material. It can withstand the rigors of medical procedures and equipment, ensuring long-lasting performance. Furthermore, stainless steel wire is biocompatible, meaning it is not harmful to living tissues and can be safely used within the human body. This makes it suitable for various medical devices such as surgical instruments, orthopedic implants, and cardiovascular stents. Overall, stainless steel wire is a versatile and reliable material that meets the stringent requirements of medical applications. Its corrosion resistance, strength, durability, and biocompatibility make it an excellent choice for use in the medical field.

- Q: What are the different types of stainless steel wire screens for windows?

- For windows, there is a variety of stainless steel wire screens available, each with its own unique features and benefits. 1. Plain Weave Screens: These screens consist of stainless steel wires woven in a simple crisscross pattern. They are the most common and cost-effective option, offering basic protection against insects and debris. 2. Twill Weave Screens: Twill weave screens are similar to plain weave screens but have a more intricate pattern. This results in a tighter weave and increased strength, making them more resistant to damage. 3. Dutch Weave Screens: Dutch weave screens have a thicker warp wire and a thinner weft wire. This design creates a tight mesh with smaller openings, providing enhanced protection against smaller insects and pests. 4. Fine Mesh Screens: Fine mesh screens have a higher number of wires per inch, resulting in a tighter weave. These screens are specifically designed to keep out even the smallest insects, such as gnats and no-see-ums. 5. Stainless Steel Security Screens: Security screens are made from a heavier gauge stainless steel wire mesh, offering enhanced strength and security. These screens are highly durable and can withstand forced entry attempts, making them ideal for high-security applications. 6. Solar Screens: Solar screens are designed to block a significant amount of sunlight and UV rays while still allowing for airflow and visibility. They are often used in hot climates to reduce heat gain and improve energy efficiency. When choosing a stainless steel wire screen for your windows, it is essential to consider your specific needs and requirements. Factors such as insect protection, strength, durability, visibility, and energy efficiency should be taken into account to select the appropriate screen.

- Q: What are the different types of stainless steel wire rope grips?

- There are several different types of stainless steel wire rope grips, including duplex wire rope grips, simplex wire rope grips, and U-bolt wire rope grips.

- Q: Is stainless steel wire suitable for wire winding?

- Indeed, wire winding is a suitable application for stainless steel wire. Renowned for its robustness, longevity, and ability to withstand corrosion, stainless steel wire is widely favored in numerous fields, including wire winding. Its remarkable flexibility enables effortless shaping and coiling into tight spirals or spools without compromising its structural soundness. Moreover, stainless steel wire comes in various grades and thicknesses, facilitating customization to meet specific wire winding needs. Consequently, stainless steel wire emerges as an unwavering and adaptable choice for wire winding endeavors.

- Q: Why is there stainless steel bright silk, what is the difference between it and stainless steel wire?

- Stainless steel wire drawing (stainless, steel, wire, drawing) pull out the wire rod or wire billet from the die hole of the drawing die under drawing force to produce the plastic processing of the small section steel wire or the non-ferrous metal line. Metal wires of different shapes and sizes of various metals and alloys can be drawn by drawing. The drawn wires are precise in size and smooth in surface, and the drawing equipment and die used are simple and easy to manufacture.

Send your message to us

Carbon Steel Welding Wires Electrodes Carbon

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords