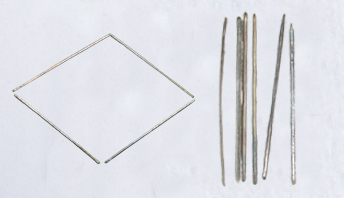

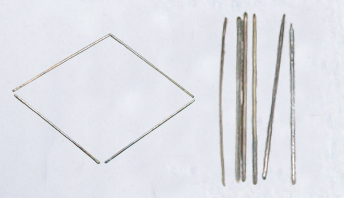

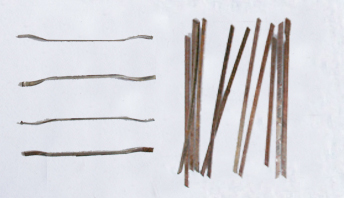

Heat-resistant stainless steel fibers melt pumping

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Fiber Grade:

The grades of steel fiber should be suitably selected based on the temperature and atmosphere.

Physical, Mechanical and corrosion resistant properties of stainless steel fiber

| 304 | 310 | 330 | 446 | 430 |

Melting Point Range ℃ | 1400-1425 | 1400-1450 | 1400-1425 | 1425-1510 | 1425-1510 |

Elastic modulus at 870℃ | 12.66 | 12.66 | 13.71 | 9.84 | 8.44 |

Tensile strength at 870℃ | 127 | 155 | 197 | 54 | 48 |

Thermal expansion coefficient at | 20.16 | 18.58 | 17.64 | 13.14 | 13.68 |

Heat conductance at 500℃ | 21.5 | 18.7 | 21.6 | 24.4 | 26.3 |

Specific gravity at romm temperature, g/cm³ | 8.0 | 8.0 | 8.0 | 7.5 | 7.8 |

Loss of weight (%) after 1000 hours of circulating oxidization at 982℃(%) | 70(100h) | 13 | 18 | 4 | 70(100h) |

*Violent circulating state in air | 870 | 1035 | 1035 | 1175 | 870 |

982 | 1050 | 1150 | 1095 | 815 | |

Corrosion in H2S,Mil/yr | 200 | 100 | / | 100 | 200 |

Recommended max operating temperature when it is used in SO2℃ | 800 | 1050 | / | 1025 | 800 |

Corrosion in natural gas at 815℃ |

| 3 |

| 4 | 12 |

Corrosion in coking coal gas at 982℃ | 225 | 25 | 75 | 14 | 236 |

Nitrogenization in anhydrous ammonia at 525℃ | 80 | 55 | 20 | 175 | <304# |

Corrosion by CH2 at 454℃, Mil/yr | 4.8 | 2.3 |

| 8.7 | 21.9 |

Carbon pick-up of alloy % with solids carbonized at 982℃ for 24 hours and 40 times of circulations, % | 1.40 | 0.02 | 0.08 | 0.07 | 1.03 |

- Q: Can stainless steel wire be used for electrical conductivity?

- Yes, stainless steel wire can be used for electrical conductivity. While stainless steel is not as conductive as materials like copper or aluminum, it still has a relatively high electrical conductivity compared to other metals. This makes it suitable for various electrical applications, such as in electrical wiring, heating elements, and electrical connectors. Stainless steel wire also offers the advantage of being resistant to corrosion, making it a durable and reliable choice for electrical conductivity in environments where moisture or harsh conditions may be present. However, it is important to note that the electrical conductivity of stainless steel can vary depending on its composition and specific alloy.

- Q: Can stainless steel wire be used for electrical resistors?

- Yes, stainless steel wire can be used for electrical resistors. Stainless steel has a high resistance to electrical current flow, making it suitable for use as a resistor material in various applications.

- Q: Can stainless steel wire be used for wire wrapping?

- Yes, stainless steel wire can be used for wire wrapping. Stainless steel wire is a popular choice for wire wrapping as it is durable, strong, and resistant to corrosion. It is often used in jewelry making to create intricate designs and secure gemstones or beads. Stainless steel wire is available in various gauges and finishes, allowing for a wide range of creative possibilities in wire wrapping projects.

- Q: Stainless steel wire why rust?

- Stainless steel surface adhesion contains acid, alkali and salt substances (such as decoration wall caustic soda, lime water splash), causing local corrosion.

- Q: Can stainless steel and nickel titanium wire be welded together?

- Then the rest is the way to the welder, welding carbon steel, stainless steel used techniques have to practice the nickel nickel welding material, after all.

- Q: What are the different wire tensile strength classes available for stainless steel wire?

- Stainless steel wire comes in various classes with different levels of tensile strength. This strength is a measure of the maximum load the wire can bear before breaking. The most commonly used classes for stainless steel wire include 302, 304, 316, and 17-7. For instance, 302 stainless steel wire has a tensile strength of approximately 185,000 to 225,000 psi. It is often utilized in applications that demand good corrosion resistance and moderate strength. On the other hand, 304 stainless steel wire has a slightly higher tensile strength range of about 185,000 to 230,000 psi. It is widely employed due to its exceptional corrosion resistance, formability, and weldability. If higher tensile strength is required, 316 stainless steel wire is the go-to option. It offers a range of around 200,000 to 250,000 psi, providing superior corrosion resistance compared to 302 and 304 stainless steel. It is particularly suitable for marine environments or applications exposed to harsh chemicals. For the highest tensile strength among these classes, one should consider 17-7 stainless steel wire. It has a range of 220,000 to 250,000 psi. This precipitation-hardening alloy excels in strength, corrosion resistance, and fatigue resistance. It is commonly found in aerospace, automotive, and medical applications. Having these diverse tensile strength classes allows manufacturers to select the appropriate stainless steel wire based on their specific application requirements.

- Q: Is stainless steel wire suitable for wire rope shackles?

- Stainless steel wire is indeed appropriate for wire rope shackles. Renowned for its ability to resist corrosion, stainless steel is a perfect choice for situations in marine and outdoor settings where exposure to moisture and other corrosive elements is prevalent. By offering durability, strength, and resistance to rust and corrosion, stainless steel wire rope shackles guarantee their reliability and longevity in a wide range of applications, including lifting, rigging, and towing. Furthermore, these shackles boast high tensile strength and can endure substantial loads, rendering them suitable for demanding and heavy-duty operations.

- Q: Can stainless steel wire be supplied in wooden reels?

- Yes, stainless steel wire can be supplied in wooden reels. Wooden reels are commonly used for packaging and transporting various types of wires, including stainless steel wire. The wooden reels provide a sturdy and durable container for the wire, protecting it from damage during shipping and handling. Additionally, the wood used in these reels is often treated to prevent moisture absorption, ensuring the wire remains in good condition.

- Q: What are the different wire surface treatments available for stainless steel wire?

- There are several different wire surface treatments available for stainless steel wire. These treatments are applied to the surface of the wire to enhance its properties and improve its performance in various applications. 1. Passivation: Passivation is a common treatment for stainless steel wire. It involves the use of a chemical solution to remove any impurities or contaminants from the surface of the wire. This helps to improve the corrosion resistance of the wire and extend its lifespan. 2. Electro-polishing: Electro-polishing is another surface treatment for stainless steel wire. It involves the use of an electrical current and an electrolyte solution to remove a thin layer of material from the surface of the wire. This process helps to smooth out any imperfections and improve the surface finish of the wire. 3. Coating: Coating is a popular treatment for stainless steel wire, especially for applications that require enhanced corrosion resistance or improved electrical conductivity. There are various coating options available, including zinc coating, nickel coating, and polymer coating. These coatings provide a protective layer on the surface of the wire, preventing it from coming into direct contact with the environment and reducing the risk of corrosion. 4. Annealing: Annealing is a heat treatment process that involves heating the stainless steel wire to a specific temperature and then slowly cooling it. This treatment helps to relieve internal stresses, improve the ductility of the wire, and enhance its mechanical properties. 5. Shot blasting: Shot blasting is a mechanical treatment that involves propelling small metal particles at high speed onto the surface of the stainless steel wire. This process helps to remove any scale, rust, or contaminants from the surface of the wire and improve its appearance. These are just a few examples of the different wire surface treatments available for stainless steel wire. The choice of treatment depends on the specific requirements of the application and the desired properties of the wire. It is important to select the appropriate treatment to ensure optimal performance and longevity of the wire in its intended use.

- Q: What are the different strength options available for stainless steel wire?

- Different applications and requirements can be catered to by the availability of stainless steel wire in various strength options. The strength of stainless steel wire is typically determined by its alloy composition, which includes the types and amounts of elements present in the steel. There are several common strength options for stainless steel wire: 1. Soft or Annealed: This option offers the lowest strength and is commonly used in applications that require flexibility and easy bending, such as wire mesh, wire ropes, and craft projects. 2. Half-Hard: This option provides a moderate level of strength and is frequently utilized in applications that require both flexibility and some resistance to deformation, such as springs, jewelry findings, and wire forming. 3. Full-Hard: This option is characterized by high strength as the stainless steel wire has been fully cold-worked to maximize its strength and hardness. It is commonly employed in applications that demand high tensile strength and stiffness, such as piano wire, springs, and structural components. 4. Extra-Hard: This is the highest strength option available for stainless steel wire. It is typically used in specialized applications that require extreme strength and resistance to deformation, such as surgical instruments, aircraft cables, and high-performance springs. In addition to these strength options, further customization of stainless steel wire is possible by selecting specific grades or alloys that offer varying levels of strength, corrosion resistance, and other desired properties. When choosing the appropriate strength option for stainless steel wire, it is crucial to consider the specific requirements of your application.

Send your message to us

Heat-resistant stainless steel fibers melt pumping

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords