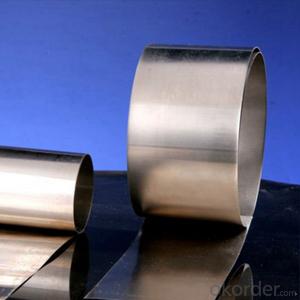

Heat Color Stainless Steel

Heat Color Stainless Steel Related Searches

Paint For Galvanized Steel Paint For Stainless Steel Heat Color Stainless Steel Stainless Steel Color Paint Stainless Steel Color Galvanized Steel Paint Black Stainless Steel Paint Liquid Stainless Steel Paint Stainless Steel Spray Paint Rustoleum Stainless Steel PaintHot Searches

Used Foam Board Insulation For Sale Magnesium Oxide Board For Sale Hdf Board For Sale sintra board for sale High Mast Light Price List Solar High Mast Light Specification Gypsum Board Price Per Sheet In India High Mast Light Specification High Density Mdf Board Suppliers 5 8 Type X Gypsum Board Price Stage Light Price Solar Inverter Fault Light Polyurethane Insulation Board Price Mdf Price Per Sheet Pre Laminated Board Price List 4Mm Mdf Sheet 1220X2440Mm Price Led Light Manufacturers Solar Inverter Pcb Board 6Mm Mdf Board Price 18Mm Ply Board PriceHeat Color Stainless Steel Supplier & Manufacturer from China

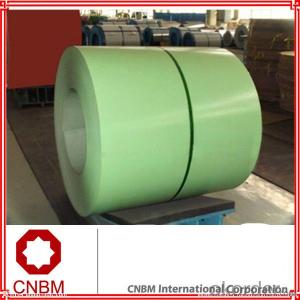

Okorder.com is a professional Heat Color Stainless Steel supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Heat Color Stainless Steel firm in China.Hot Products

FAQ

- Yes, stainless steel pipes can be insulated with polylactic acid (PLA). PLA is a biodegradable and renewable thermoplastic polymer that is derived from renewable sources such as corn starch or sugar cane. It is commonly used as an insulation material due to its low thermal conductivity and good insulation properties. To insulate stainless steel pipes with PLA, a layer of PLA insulation can be applied around the pipes. This insulation layer helps to reduce heat loss or gain, prevent condensation, and improve energy efficiency. The PLA insulation can be in the form of sheets or tubes that can be easily wrapped around the pipes. One of the advantages of using PLA insulation is its eco-friendly nature. PLA is biodegradable and does not release harmful toxins during its production or disposal. It is also a sustainable material as it can be derived from renewable resources. Additionally, PLA insulation is resistant to moisture and has good dimensional stability, making it suitable for various applications. However, it is important to note that PLA has a lower melting point compared to stainless steel, so it may not be suitable for high-temperature applications. If the pipes are exposed to extreme heat, alternative insulation materials with higher melting points should be considered. In conclusion, stainless steel pipes can be effectively insulated with polylactic acid (PLA) insulation. PLA insulation offers good thermal properties, is eco-friendly, and can contribute to energy savings. However, it is essential to consider the temperature limits of PLA when using it for insulation purposes.

- No, stainless steel pipes do not require any special coatings as they are already highly resistant to corrosion and do not need additional protection.

- Yes, stainless steel pipes are generally resistant to UV radiation. The high chromium content in stainless steel helps protect it from the damaging effects of UV radiation, making it a suitable choice for outdoor applications.

- The main difference between Type 304 and Type 316 stainless steel pipes is their composition and corrosion resistance. Type 304 is a basic chromium-nickel stainless steel with good corrosion resistance in mild environments, while Type 316 contains molybdenum, which enhances its resistance to corrosion, especially in chloride-rich environments. This makes Type 316 more suitable for applications in marine and coastal environments, as well as industries where exposure to harsh chemicals or high temperatures is common.

- To prevent backflow in stainless steel pipes, there are a few key measures that can be taken. 1. Install a backflow preventer: This is a mechanical device that is installed in the pipe system to ensure that water flows in one direction and prevents any backflow. There are different types of backflow preventers available, such as check valves, double check valves, and reduced pressure zone devices. The selection of the appropriate backflow preventer depends on the specific requirements of the system and local codes and regulations. 2. Regular maintenance and inspection: It is important to regularly inspect the backflow preventer and ensure it is functioning properly. Any signs of wear or damage should be addressed immediately to prevent potential backflow issues. Regular maintenance can also include cleaning and replacing any worn-out parts to ensure optimal performance. 3. Pressure regulation: Maintaining proper pressure in the stainless steel pipes can also help prevent backflow. High pressure can cause water to flow in the opposite direction, leading to backflow. By installing pressure regulators or pressure-reducing valves, the water pressure can be controlled and maintained within the recommended range. 4. Air gaps: Incorporating air gaps in the system can provide an additional layer of protection against backflow. An air gap is a physical separation between the water source and the point of use, ensuring that there is no direct connection that could allow backflow to occur. 5. Adequate system design: Proper system design is crucial in preventing backflow. By ensuring that the stainless steel pipes have the correct sizing, appropriate slope, and proper connections, the risk of backflow can be minimized. Additionally, locating the backflow preventer in an easily accessible area can facilitate regular maintenance and inspection. By implementing these preventive measures, the risk of backflow in stainless steel pipes can be significantly reduced, promoting the safe and efficient flow of water in the system.

- Preventing oxidation in stainless steel pipes can be achieved through several methods. One way to effectively prevent oxidation is by applying a protective coating or finish on the surface of the pipes. Various types of coatings, including paints, epoxy, or polyurethane, can serve as barriers that prevent oxygen from coming into contact with the stainless steel, thus reducing the risk of oxidation. Furthermore, keeping the pipes clean and well-maintained is crucial in preventing oxidation. It is essential to eliminate any accumulated dirt, debris, or corrosive substances from the surface of the pipes. This can be accomplished using mild detergents or specialized cleaning agents specifically designed for stainless steel. Ensuring proper ventilation in the installation area is another preventive measure. Sufficient ventilation helps minimize the presence of moisture or humidity, which can accelerate the oxidation process. Additionally, keeping the pipes dry and avoiding prolonged exposure to water or moisture is vital in preventing oxidation. Lastly, selecting the appropriate grade of stainless steel for the intended application is important. Different grades of stainless steel offer varying levels of resistance to oxidation. For instance, austenitic stainless steel grades like 304 and 316 are highly resistant to oxidation and are commonly used in applications where corrosion resistance is crucial. In conclusion, employing a combination of preventive measures, such as protective coatings, regular cleaning, proper ventilation, and selecting the appropriate stainless steel grade, can effectively prevent oxidation in stainless steel pipes.

- Stainless steel pipes are generally more durable, corrosion-resistant, and have higher heat resistance compared to brass pipes. Additionally, stainless steel pipes are often more cost-effective in the long run due to their longevity and low maintenance requirements. Brass pipes, on the other hand, are known for their excellent conductivity and aesthetic appeal. Ultimately, the choice between stainless steel and brass pipes depends on the specific needs and preferences of the application.

- In stainless steel applications, the main difference between a pipe and a tube lies in their structural composition and intended use. A pipe is typically designated by its inner diameter (ID) and wall thickness, and is primarily designed to transport fluids or gases. It is usually round in shape and is often used in industries such as oil and gas, chemical processing, and plumbing. Pipes are manufactured using a variety of methods, including seamless or welded processes. On the other hand, a tube is characterized by its outer diameter (OD) and wall thickness, and is commonly used for structural or mechanical purposes. Tubes can have various shapes, such as round, rectangular, or square, and are often utilized in industries such as construction, automotive, and aerospace. Tubes can also be produced through seamless or welded methods. In terms of manufacturing, pipes generally undergo stricter tolerances and quality control measures due to their transportation function, while tubes may have less stringent requirements as they are primarily used for structural applications. Additionally, pipes are commonly measured and sold by their nominal sizes, while tubes are typically specified by their actual dimensions. Both pipes and tubes can be made from stainless steel, which offers excellent corrosion resistance and durability. Stainless steel is a versatile material that is suitable for a wide range of applications, including those requiring high temperatures or exposure to harsh environments. Overall, the key distinction between a pipe and a tube in stainless steel applications is their intended purpose and structural characteristics. While pipes are designed for fluid or gas transportation, tubes are utilized for structural or mechanical applications.