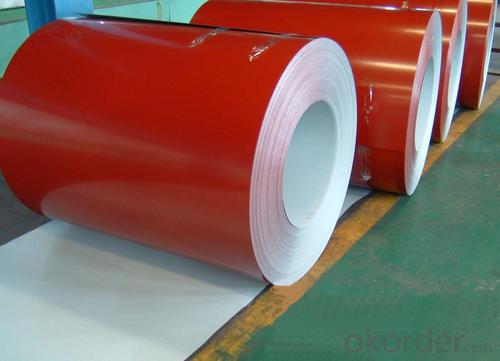

color Coated Galvanized cold Rolled Steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

1. Thickness: 0.12mm-1.3mm

2. Width: 600mm-1250mm

3. Length: According to client's demands

4. Top paint: 15 to 25 um (5 um + 12-20 um)

Back paint: 7 +/- 2 um

5. Gloss: Normal or High gloss

6. Zinc coating: Z50-Z275G/psm

7. Inside Diameter: 508mm/610mm

8. Outside Diameter: 1000mm-1500mm

9. Coil weight: 3-8 tons

10. Payment: T/T, L/C, D/P, Paypal, Western Union

11. Trade Term: FOB, CFR, CIF

12. MOQ: 25 Mt

13. Package: Export standard package or as request

14. Shipment: By container

15. Standard: AISI, ASTM, BS, DIN, GB, JIS

16. Grade: JIS G3322, CGLCC, ASTM A755, CS-B

| Resin constructure Technique of production | Double painting and double baking process |

| Productivity | 150,000Tons/year |

| Thickness | 0.12-1.3mm |

| Width | 600-1250mm |

| Coil Weight | 2-7 Tons |

| Inside Diameter | 508mm Or 610mm |

| Outside Diameter | 1000-1500mm |

| Zinc Coating | Z50-Z275G |

| Painting | Top: 15 to 25 um (5 um + 12-20 um) back: 7 +/- 2 um |

| Standard | JIS G3322 CGLCC ASTM A755 CS-B |

| SurfSurface coating coloace coating type | PE, SMP, HDP, PVDF |

| Back side coatingcolor | Light grey, white and so on |

| Application | PPGI is featured with light-weight, good looking and anticorrosion. It can be processed directly, mainly used for construction industry, home electronic apparatus industry, electronic apparatus industry, furniture industry and transportation. |

- Q: How are steel coils used in the aerospace industry?

- Steel coils are used in the aerospace industry for various applications including manufacturing aircraft components, structural supports, and engine parts. The coils are typically processed and shaped into specific forms such as sheets or plates, which are then used to construct critical components of aircrafts, ensuring strength, durability, and performance.

- Q: How many pounds can steel lift?

- Well, metal steel can lift an infinite amount of weight if necessary, BUT it can only withstand tensile PRESSURE up to a certain amount. That amount depends on what kind of steel you have; you can have low and high carbon steel, for example, here are some maximum tensile forces a lot of common steels can withstand: Coated Steel (Galvanized): 200-215 GPa Terne Coated Stainless Steel: 189 - 197 GPa Terne Coated Steel: 185-200 GPa AirMet100 High alloy steel: 193-203 GPa AF1410: 203 -213 GPa 17% Cobalt Steel: 199-209 GPa 36% Cobalt Steel: 199-209 GPa 6% Tungsten Steel: 218-229 GPa A-286: 201-211 GPa N-115: 201-211 GPa 250 Maraging Steel: 183 - 192 GPa 280 (300) Maraging Steel: 183-192 GPa And that's just Coated and High-alloy steels, I have yet to go through Cast Irons, Commercial-purity Iron, Low alloy steel, low carbon steel, medium alloy steel, medium carbon steel, stainless steels, tool steels, and very low carbon steels, and I'm not even sure if this is a complete list of the different types of steels in the world. TL;DR We need more information. EDIT: By pressure, I mean the negative tensile type of pressure. EDIT 2: At it's thinnest point, most supportive skeletal features will be able to support 132 pounds quite easily. However, if you want to make an effective light-weight strong skeleton, I would suggest using aluminium rather than steel.

- Q: What are the different methods of annealing steel coils?

- Steel coils can be annealed using various methods, each with its own advantages and applications. Full annealing, process annealing, and spheroidize annealing are the main methods. The most common method is full annealing, wherein the steel coils are heated above their critical point (usually between 800 and 900 degrees Celsius or 1472 and 1652 degrees Fahrenheit) and then slowly cooled in a controlled manner. This process refines the grain structure of the steel, making it softer and more ductile. Full annealing is employed to relieve internal stresses, enhance machinability, and improve the overall mechanical properties of the steel. Process annealing, sometimes called subcritical annealing or stress relief annealing, is used to reduce the hardness and brittleness of steel coils. It involves heating the coils below their critical point (typically between 550 and 650 degrees Celsius or 1022 and 1202 degrees Fahrenheit) and then slowly cooling them. This method relieves internal stresses that may have developed during previous manufacturing processes like cold working or welding. Process annealing is commonly used to enhance the formability and toughness of steel coils. Spheroidize annealing is a specialized form of annealing that softens high carbon and alloy steels. It entails heating the steel coils slightly below their critical point (usually between 650 and 700 degrees Celsius or 1202 and 1292 degrees Fahrenheit) and holding them at that temperature for an extended period. This allows the carbides within the steel to transform into rounded or spheroidal shapes, thereby increasing machinability and ductility. Spheroidize annealing is frequently employed in the production of cutting tools, bearings, and other applications that require improved machinability. In addition to these main methods, there are variations and specialized techniques like recrystallization annealing, intercritical annealing, and solution annealing. Each method has specific parameters and temperature ranges. The choice of annealing method depends on factors such as the type of steel, desired mechanical properties, and intended application of the steel coils.

- Q: Are steel coils used in construction?

- Yes, steel coils are commonly used in construction. They are often used in the manufacturing of structural components, such as beams, columns, and trusses, as well as in the construction of metal buildings and infrastructure projects. Steel coils provide strength, durability, and versatility to various construction applications.

- Q: When i was 15 i got caught steeling at Super A yes i know i cant believe it. They didnt call the cops or anything they released me to my aunt they took my name and adress and everythimg they said it wouldnt be on my record. But I'm not so sure. Will it be on my record if they didn't call the cops?i live in california. Is there any way i can check my record?

- Steeling? What's that? Did you take a piece of steel and weld it? I am confused?

- Q: Can steel coils be coated with PVC?

- Yes, steel coils can be coated with PVC. PVC coating provides a protective layer that helps prevent corrosion and enhances the durability of steel coils.

- Q: What are the common coil coating methods?

- The common coil coating methods include roll coating, spray coating, and coil coating with pre-painted metal substrates.

- Q: Can steel coils be used in electrical applications?

- Certainly, electrical applications can make use of steel coils. In the realm of electrical circuits, steel coils often serve as magnetic cores in transformers and inductors, which are indispensable components. The steel employed in these coils typically consists of high-quality electrical steel, possessing distinct magnetic attributes, including low core losses and high permeability. These attributes empower the steel coils to efficiently transmit electrical energy between various circuit components. Furthermore, steel coils can also find utility in other electrical applications, such as the construction of electric motors and generators. Taking everything into account, steel coils are extensively employed in electrical applications due to their magnetic properties and their capacity to handle high currents and temperatures.

- Q: How do steel coils contribute to the manufacturing of electrical appliances?

- Steel coils are essential components in the manufacturing of electrical appliances as they are used to create the core of transformers and electromagnets. These coils, made from steel, provide the necessary magnetic field required for the functioning of electrical appliances such as refrigerators, televisions, and washing machines.

- Q: iam talking abt carbon steel of composition:-C=0.15wt% Mn=0.60wt% P=0.035wt% S=0.04wt% Cu=0.20 (min)wt%....

- The composition of the steel is almost tertiary to many other considerations, except that there are certain elements and percentages of elements which tend to affect the crystaline structure in the steel. The most basic question is whether the crystaline arrangement of atoms in the steel is martensitic or austenitic, and many factors influence that. In general, martensitic structure is magnetic and austenitic structure doesn't respond much to magnetic fields, but there are varying degrees of martensitic and austenitic -- there is never a pure state. Read the articles at bottom.

Send your message to us

color Coated Galvanized cold Rolled Steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords