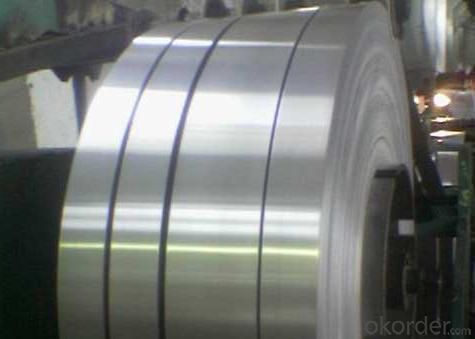

Good Quality Stainless Steel Strips 316L

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Good Quality Stainless Steel Strips 316L

1. Chemical Composition of Good Quality Stainless Steel Strips 316L

C | Si | Mn | P | S | Ni | Cr |

Max0.03 | max1.00 | max2.00 | max0.045 | max0.03 | 10.00-14.00 | 16.00-18.00 |

2. Mechanical Properties of Good Quality Stainless Steel Strips 316L

Yield Strength | Tensile | Elongation | Hardness (HV) | Hardness (HRB) |

≥175 | ≥480 | ≥40 | ≤200 | ≤90 |

3. Standard of Good Quality Stainless Steel Strips 316L:

AISI, ASTM, GB, EN, DIN, JIS

4. Surface of Good Quality Stainless Steel Strips 316L

2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size of Good Quality Stainless Steel Strips 316L

Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ of Good Quality Stainless Steel Strips 316L

1 Ton

7. Payment Terms of Good Quality Stainless Steel Strips 316L

T/T or L/C

8. Packing of Good Quality Stainless Steel Strips 316L

Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery Time of Good Quality Stainless Steel Strips 316L:

Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q: Is stainless steel wire suitable for wire wrapping?

- Indeed, stainless steel wire is highly suitable for wire wrapping purposes. Possessing great strength, durability, and resistance to corrosion, it is an exceptional choice for this craft. It finds extensive use in the creation of jewelry, as it imparts stability and support to the beads or stones being wrapped. Moreover, stainless steel wire is available in different thicknesses, facilitating versatility in wire wrapping techniques. It can be effortlessly manipulated and shaped, all while maintaining its strength, thereby ensuring secure placement of the wrapped items. Overall, stainless steel wire emerges as a dependable and widely preferred option for wire wrapping endeavors.

- Q: What are the different wire surface quality options available for stainless steel wire?

- There are several wire surface quality options available for stainless steel wire, depending on the specific requirements and applications. These options include: 1. Bright Surface: This is the most common and standard surface quality for stainless steel wire. It is characterized by a smooth and shiny surface finish, which is achieved through various surface treatments such as pickling, annealing, and polishing. 2. Matte Surface: Some applications require a less reflective surface finish. In such cases, stainless steel wire can be treated to achieve a matte or satin-like appearance. This surface finish is achieved through processes like shot blasting or brushing. 3. Coated Surface: Stainless steel wire can also be coated with various materials to provide additional protection or enhance certain properties. Common coatings include zinc plating, epoxy coating, or nylon coating. These coatings not only improve the wire's surface quality but also provide corrosion resistance or insulation properties. 4. Passivated Surface: Passivation is a chemical process used to remove impurities and contaminants from the surface of stainless steel wire. This treatment enhances the wire's corrosion resistance, improves its surface quality, and ensures a clean and oxide-free surface. 5. Electropolished Surface: Electropolishing is another surface treatment option available for stainless steel wire. It involves immersing the wire in an electrolytic bath and applying an electric current to remove a thin layer of material. This process not only improves the wire's surface quality but also enhances its corrosion resistance and improves its cleanability. 6. Ultra-clean Surface: In certain sensitive applications such as medical or pharmaceutical industries, stainless steel wire may require an ultra-clean surface free from any contaminants or impurities. These wires undergo extensive cleaning and sterilization procedures to achieve the highest level of surface quality. It is important to select the appropriate wire surface quality option based on the specific requirements of the application, considering factors such as corrosion resistance, aesthetics, cleanliness, and functionality. Consulting with a stainless steel wire manufacturer or supplier can help in determining the most suitable surface quality option for a particular application.

- Q: Can stainless steel wire hangers be used for hanging heavy coats?

- Indeed, heavy coats can be hung using stainless steel wire hangers. Stainless steel is renowned for its robustness and longevity, rendering it appropriate for upholding weightier articles like coats. The wire structure of these hangers imparts an additional degree of steadfastness, guaranteeing that they can endure the burden of heavy coats without succumbing to bending or breaking. Furthermore, stainless steel exhibits resistance to rust and corrosion, endowing it with reliability for prolonged utilization. However, it is prudent to always verify the weight limit stipulated by the hanger manufacturer to ascertain its capacity in safely supporting the weight of your particular heavy coat.

- Q: How can I screw the stainless steel tube?

- Self screws can be, is a bit slippery, unlike the iron pipe on some good moments

- Q: Can stainless steel wire be used for safety wire?

- Yes, stainless steel wire can be used for safety wire. It is commonly used in safety wire applications due to its high strength, corrosion resistance, and durability.

- Q: What are the standard spool sizes for stainless steel wire?

- The standard spool sizes for stainless steel wire vary depending on the specific application and manufacturer. However, common spool sizes for stainless steel wire range from 1 lb (0.45 kg) to 1000 lbs (453.5 kg) or more.

- Q: What are the different wire forming techniques used for stainless steel wire?

- Stainless steel wire can be shaped into different forms and structures using various wire forming techniques. These techniques serve different purposes and are commonly employed in different applications. One commonly used technique is wire drawing. This involves reducing the diameter of the stainless steel wire by pulling it through a series of dies. Besides achieving the desired diameter, this process also enhances the wire's mechanical properties and surface finish. Another technique is wire bending, which involves bending or curving the stainless steel wire into specific shapes. This can be done manually with hand tools or through automated bending machines. Wire bending finds applications in springs, hooks, and wire forms. Wire coiling is yet another technique used for stainless steel wire. It involves winding the wire around a mandrel or cylindrical object to create coils of various sizes and shapes. Coiling is commonly used in springs, electrical contacts, and jewelry. Wire welding is an essential technique for stainless steel wire. TIG or MIG welding methods are used to join stainless steel wires together or attach them to other components. This technique is widely used in fabricating wire mesh, wire baskets, and other wire-based structures. Lastly, wire mesh weaving is a specialized technique for creating stainless steel wire mesh. Multiple wires are interlaced in a crisscross pattern to form a mesh with specific mesh sizes and patterns. Wire mesh is commonly used in filtration, sieving, and screening applications. In conclusion, these wire forming techniques provide a wide range of options for shaping stainless steel wire, enabling its use in various industries and applications.

- Q: Is stainless steel wire suitable for wire EDM applications?

- Yes, stainless steel wire is suitable for wire EDM (Electrical Discharge Machining) applications. Wire EDM is a precision machining process that utilizes a thin wire to cut through a workpiece using electrical discharges. Stainless steel wire is commonly used in wire EDM due to its excellent electrical conductivity, high tensile strength, and resistance to corrosion. These properties make it ideal for cutting a wide range of materials, including metals, alloys, and even conductive ceramics. Additionally, stainless steel wire offers good thermal stability and can withstand the high temperatures generated during the EDM process. Overall, stainless steel wire is a reliable and effective choice for wire EDM applications.

- Q: Is stainless steel wire resistant to heat?

- Yes, stainless steel wire is highly resistant to heat.

- Q: Can stainless steel wire withstand high temperatures?

- Yes, stainless steel wire can withstand high temperatures.

Send your message to us

Good Quality Stainless Steel Strips 316L

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords