All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

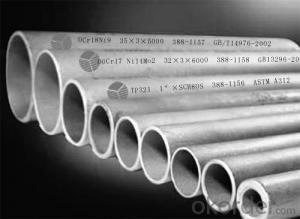

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is stainless steel used in the aerospace industry?

Stainless steel is widely used in the aerospace industry due to its exceptional strength, durability, and corrosion resistance properties. It is commonly used in the construction of aircraft structures, engine components, and various other critical parts. The high strength-to-weight ratio of stainless steel allows for lighter aircraft designs without compromising on structural integrity. Additionally, its resistance to heat and extreme temperatures makes it suitable for engines and exhaust systems. In summary, stainless steel plays a crucial role in enhancing safety, performance, and longevity in aerospace applications.

How is stainless steel used in the aerospace industry for the development of lightweight and fuel-efficient aircraft interiors?

Stainless steel is used in the aerospace industry for the development of lightweight and fuel-efficient aircraft interiors in various ways. Firstly, it is utilized in the construction of structural components such as seats, partitions, and storage compartments due to its high strength-to-weight ratio. This allows for the creation of lighter aircraft interiors, contributing to overall weight reduction and improved fuel efficiency. Additionally, stainless steel is corrosion-resistant, ensuring durability and longevity of the interior components. Moreover, it is often employed in the fabrication of galley equipment and lavatory fixtures, providing hygienic and easy-to-clean solutions. Overall, stainless steel plays a crucial role in enhancing aircraft interior design by balancing weight reduction, durability, and functionality.

How is stainless steel employed in the brewing and beverage industry?

Stainless steel is extensively used in the brewing and beverage industry due to its excellent corrosion resistance and hygienic properties. It is employed in the manufacturing of various equipment such as fermentation tanks, storage vessels, piping systems, and kegs. Stainless steel's inert nature ensures the preservation of taste and quality of beverages, while its durability and ease of cleaning make it ideal for maintaining strict hygiene standards. Additionally, stainless steel's ability to withstand high temperatures and pressure enables efficient brewing and ensures the longevity of equipment in the industry.

Wholesale Stainless Steel from supplier in Libya

Our team of experts in Libya is dedicated to providing exceptional customer service and ensuring that our clients receive the highest quality Stainless Steel products. We understand the unique needs and requirements of the Libyan market and strive to deliver customized solutions that meet your specific project requirements.

Whether you need Stainless Steel pipes, tubes, fittings, or other related products, we have a wide range of options available. Our extensive inventory allows us to quickly fulfill your orders and ensure timely delivery to your project site.

In addition to our sales and procurement services, we also offer comprehensive technical support. Our team of engineers and technicians can provide guidance and assistance throughout the entire project lifecycle. From product selection and design to installation and maintenance, we are here to support you every step of the way.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and expertise to handle projects of any scale and complexity. Our strong partnerships with leading manufacturers ensure that we can offer competitive prices without compromising on quality.

At our company, we prioritize customer satisfaction and strive to build long-term relationships with our clients. We are committed to delivering exceptional service, reliable products, and valuable insights to help you succeed in your projects in Libya.

Contact us today to learn more about our Stainless Steel products and how we can assist you with your projects in Libya.

Whether you need Stainless Steel pipes, tubes, fittings, or other related products, we have a wide range of options available. Our extensive inventory allows us to quickly fulfill your orders and ensure timely delivery to your project site.

In addition to our sales and procurement services, we also offer comprehensive technical support. Our team of engineers and technicians can provide guidance and assistance throughout the entire project lifecycle. From product selection and design to installation and maintenance, we are here to support you every step of the way.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and expertise to handle projects of any scale and complexity. Our strong partnerships with leading manufacturers ensure that we can offer competitive prices without compromising on quality.

At our company, we prioritize customer satisfaction and strive to build long-term relationships with our clients. We are committed to delivering exceptional service, reliable products, and valuable insights to help you succeed in your projects in Libya.

Contact us today to learn more about our Stainless Steel products and how we can assist you with your projects in Libya.