All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

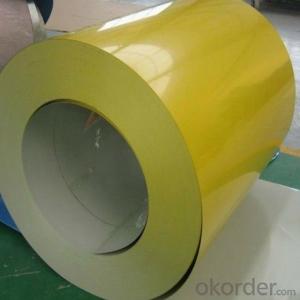

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What challenges are associated with producing high-strength steel coils for automotive safety systems?

Producing high-strength steel coils for automotive safety systems poses several challenges. One of the main challenges is the complex manufacturing process required to achieve the desired strength levels without compromising other properties, such as formability and weldability. Additionally, ensuring consistent quality control throughout the production process is crucial to meet strict safety standards. Another challenge is the cost involved in producing high-strength steel coils, as the materials and manufacturing techniques used are often more expensive than traditional steel. Lastly, keeping up with the constantly evolving automotive industry and staying ahead of the competition in terms of innovation and technology can also be a challenge.

How are steel coils prepared for the production of automotive body panels?

Steel coils are prepared for the production of automotive body panels by undergoing a series of manufacturing processes. Initially, the steel coils are unloaded and inspected for any defects or imperfections. Next, they are cleaned to remove any impurities or contaminants. The coils are then sent through a leveling process to ensure uniform thickness and flatness. After leveling, the steel coils are sheared into specific sizes and then undergo a process called blanking, where the desired shapes for the body panels are cut out. These blanks are then further processed through techniques like stamping, bending, and welding to form the final automotive body panels.

How are steel coils prepared for laser cutting?

Steel coils are prepared for laser cutting by being uncoiled and flattened to achieve a flat and even surface. The coils are then cleaned to remove any dirt, oil, or residue that may interfere with the laser cutting process. Once cleaned, the coils are usually cut into smaller, more manageable sizes before being loaded onto the laser cutting machine for precise and efficient cutting.

Wholesale Steel Coils from supplier in Cambodia

Whether you are in the construction, manufacturing, or any other industry requiring steel coils, our team is dedicated to delivering high-quality products that meet your specific requirements. We offer a wide range of steel coil options, including hot-rolled, cold-rolled, galvanized, and prepainted coils, ensuring that we can cater to various applications.

Our sales team is committed to providing excellent customer service and support throughout the entire procurement process. From initial inquiries to placing orders and arranging delivery, we strive to make the experience seamless and efficient for our clients. We understand the importance of timeliness and reliability in the business world and work diligently to meet your deadlines and expectations.

In addition to sales, we also offer comprehensive quotations to help you make informed decisions based on your budget and project specifications. Our team of experts will assess your requirements and provide competitive pricing options, ensuring that you receive the best value for your investment.

Moreover, we offer technical support services to assist you in selecting the right steel coils for your specific applications. Our knowledgeable professionals can provide guidance on material selection, product specifications, and industry standards, helping you make well-informed decisions that result in optimal performance and cost-efficiency.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to stay updated with the latest industry trends and technologies, ensuring that we offer cutting-edge solutions to our customers.

Whether you are a small business or a large corporation, we are committed to meeting your steel coil procurement needs in Cambodia. Our goal is to establish long-term partnerships with our clients based on trust, reliability, and exceptional service. Contact us today to discuss your requirements and let us assist you in achieving success in your projects.

Our sales team is committed to providing excellent customer service and support throughout the entire procurement process. From initial inquiries to placing orders and arranging delivery, we strive to make the experience seamless and efficient for our clients. We understand the importance of timeliness and reliability in the business world and work diligently to meet your deadlines and expectations.

In addition to sales, we also offer comprehensive quotations to help you make informed decisions based on your budget and project specifications. Our team of experts will assess your requirements and provide competitive pricing options, ensuring that you receive the best value for your investment.

Moreover, we offer technical support services to assist you in selecting the right steel coils for your specific applications. Our knowledgeable professionals can provide guidance on material selection, product specifications, and industry standards, helping you make well-informed decisions that result in optimal performance and cost-efficiency.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to stay updated with the latest industry trends and technologies, ensuring that we offer cutting-edge solutions to our customers.

Whether you are a small business or a large corporation, we are committed to meeting your steel coil procurement needs in Cambodia. Our goal is to establish long-term partnerships with our clients based on trust, reliability, and exceptional service. Contact us today to discuss your requirements and let us assist you in achieving success in your projects.