All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

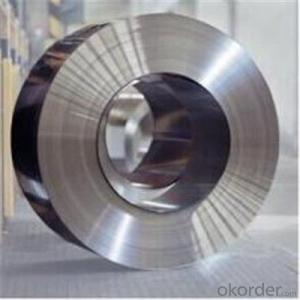

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different surface treatments for steel strips in architectural applications?

There are several surface treatments commonly used for steel strips in architectural applications. These include galvanizing, powder coating, painting, and anodizing. Galvanizing involves coating the steel with a layer of zinc to protect it from corrosion. Powder coating involves applying a dry powder to the steel and then curing it to create a durable and attractive finish. Painting involves applying a liquid paint to the steel surface, providing protection and aesthetics. Anodizing is a process that creates a protective oxide layer on the steel surface, enhancing its corrosion resistance and providing a range of color options.

How do steel strips contribute to the production of springs for heavy machinery and equipment?

Steel strips contribute to the production of springs for heavy machinery and equipment by providing the necessary raw material for manufacturing strong and durable springs. These strips are typically made from high-quality steel alloys that possess excellent strength and elasticity, essential properties for springs. The steel strips are shaped and formed into the desired spring shape and then heat-treated to enhance their mechanical properties further. This process ensures that the resulting springs can withstand heavy loads, resist fatigue, and provide reliable performance in demanding industrial applications.

What are the specifications for steel strips used in the production of components for high-performance bearings and bushings?

The specifications for steel strips used in the production of components for high-performance bearings and bushings typically include criteria such as specific alloy composition, precise dimensional tolerances, excellent surface finish, high strength, hardness, and resistance to wear and corrosion. These specifications ensure that the steel strips possess the necessary properties to meet the demanding requirements of high-performance bearings and bushings, enabling them to function reliably and efficiently in various industrial applications.

How are steel strips used in the shipbuilding industry?

Steel strips are used in the shipbuilding industry for various purposes, including the construction of the ship's hull, frames, and decks. These strips are often formed and shaped into different sections to provide strength, stability, and durability to the ship's structure. Additionally, steel strips are also used for the fabrication of other essential components such as bulkheads, hatch covers, and pipelines. Overall, steel strips play a crucial role in ensuring the structural integrity and resilience of ships in the shipbuilding industry.

Wholesale Steel Strips from supplier in Bolivia

Whether you are in need of Steel Strips for construction, manufacturing, or any other industry, we have the expertise to meet your specific requirements. Our wide range of products includes hot-rolled steel strips, cold-rolled steel strips, galvanized steel strips, and stainless steel strips, among others.

As a subsidiary of CNBM, a leading global company in the steel industry, we have access to a vast network of suppliers and manufacturers, ensuring that we can offer competitive prices and high-quality products. Our team of experienced professionals is dedicated to providing excellent customer service, from the initial sales inquiry to after-sales support.

We understand the unique challenges and requirements of the Bolivian market, and our local presence allows us to provide tailored solutions for your projects. Whether you need assistance with product selection, technical specifications, or logistics, our team is ready to support you every step of the way.

At our company, we prioritize customer satisfaction and strive to build long-term relationships with our clients. We believe in transparent communication, timely delivery, and reliable service. With our comprehensive range of products and dedicated support services, we are confident that we can meet your Steel Strips procurement needs in Bolivia. Contact us today to discuss your requirements and let us be your trusted partner in steel supply.

As a subsidiary of CNBM, a leading global company in the steel industry, we have access to a vast network of suppliers and manufacturers, ensuring that we can offer competitive prices and high-quality products. Our team of experienced professionals is dedicated to providing excellent customer service, from the initial sales inquiry to after-sales support.

We understand the unique challenges and requirements of the Bolivian market, and our local presence allows us to provide tailored solutions for your projects. Whether you need assistance with product selection, technical specifications, or logistics, our team is ready to support you every step of the way.

At our company, we prioritize customer satisfaction and strive to build long-term relationships with our clients. We believe in transparent communication, timely delivery, and reliable service. With our comprehensive range of products and dedicated support services, we are confident that we can meet your Steel Strips procurement needs in Bolivia. Contact us today to discuss your requirements and let us be your trusted partner in steel supply.