All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

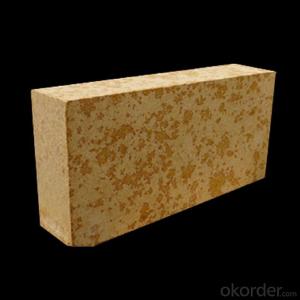

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

What are the key properties of fireclay in refractory manufacturing?

The key properties of fireclay in refractory manufacturing include high heat resistance, excellent thermal conductivity, low thermal expansion, good chemical resistance, and high mechanical strength.

What is the role of zirconium oxide in refractory materials?

Zirconium oxide, also known as zirconia, is commonly used in refractory materials due to its high heat resistance and chemical stability. It acts as a refractory lining in furnaces, kilns, and other high-temperature applications to protect against thermal shock, erosion, and corrosion. Additionally, zirconium oxide-based refractories offer excellent mechanical strength, low thermal conductivity, and good thermal insulation properties, making them ideal for withstanding extreme temperatures and harsh operating conditions.

How do raw materials impact the corrosion resistance of refractory products?

Raw materials play a crucial role in determining the corrosion resistance of refractory products. The type and quality of raw materials used in the manufacturing process directly influence the chemical composition and structure of the final product, which in turn affects its ability to withstand corrosion. Selecting the right raw materials, such as high-quality refractory aggregates and binders with low impurity levels, can enhance the corrosion resistance of refractory products, making them more durable and long-lasting in harsh environments.

How does the addition of spinel affect the thermal shock resistance of refractories?

The addition of spinel to refractories improves their thermal shock resistance. Spinel has a high melting point and excellent thermal stability, which helps to increase the refractory's ability to withstand rapid temperature changes without cracking or failure. Additionally, spinel's crystal structure allows it to accommodate thermal expansion and contraction more effectively, further enhancing the refractory's resistance to thermal shock.

Wholesale Raw Materials For Refractory from supplier in Bolivia

We understand the unique needs of the refractory industry in Bolivia and strive to provide tailored solutions to our clients. Our team of experts is dedicated to understanding your specific requirements and offering the most suitable raw materials for your refractory products.

In addition to our sales and quoting services, we also provide technical support to ensure that you have the necessary information and guidance for the successful implementation of your projects. Our technical experts are available to assist you in selecting the right raw materials, optimizing their performance, and resolving any technical issues that may arise.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources. This enables us to provide comprehensive procurement services, ensuring that you have a reliable and efficient supply chain for your raw materials. We work closely with our suppliers to maintain the highest quality standards and ensure timely deliveries.

Our extensive product portfolio includes a wide range of raw materials for refractory products, such as various types of minerals, aggregates, binders, and additives. We source these materials from reputable suppliers around the world, ensuring that they meet the required specifications and quality standards.

With our years of market experience in Bolivia, we have developed strong relationships with local suppliers and customers. This gives us valuable insights into the local market dynamics and enables us to offer customized solutions that cater to the specific needs of our clients. We understand the importance of cost-effectiveness and strive to provide competitive pricing without compromising on quality.

Choosing us as your supplier of raw materials for refractory products in Bolivia means partnering with a reliable and knowledgeable team that is committed to your success. We are dedicated to exceeding your expectations and helping you achieve your project goals. Contact us today to discuss your requirements and find out how we can support your business.

In addition to our sales and quoting services, we also provide technical support to ensure that you have the necessary information and guidance for the successful implementation of your projects. Our technical experts are available to assist you in selecting the right raw materials, optimizing their performance, and resolving any technical issues that may arise.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources. This enables us to provide comprehensive procurement services, ensuring that you have a reliable and efficient supply chain for your raw materials. We work closely with our suppliers to maintain the highest quality standards and ensure timely deliveries.

Our extensive product portfolio includes a wide range of raw materials for refractory products, such as various types of minerals, aggregates, binders, and additives. We source these materials from reputable suppliers around the world, ensuring that they meet the required specifications and quality standards.

With our years of market experience in Bolivia, we have developed strong relationships with local suppliers and customers. This gives us valuable insights into the local market dynamics and enables us to offer customized solutions that cater to the specific needs of our clients. We understand the importance of cost-effectiveness and strive to provide competitive pricing without compromising on quality.

Choosing us as your supplier of raw materials for refractory products in Bolivia means partnering with a reliable and knowledgeable team that is committed to your success. We are dedicated to exceeding your expectations and helping you achieve your project goals. Contact us today to discuss your requirements and find out how we can support your business.

Hot Search

- Monolithic Refractories in Eritrea

- Ceramic Fiber Products in Finland

- Refractory Bricks in Cameroon

- Raw Materials For Refractory in Montenegro

- Refractory Bricks in Mauritania

- Ceramic Fiber Products in Brazil

- Raw Materials For Refractory in Bolivia

- Refractory Bricks in Armenia

- Refractory Bricks in Colombia

- Refractory Bricks in Croatia