All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

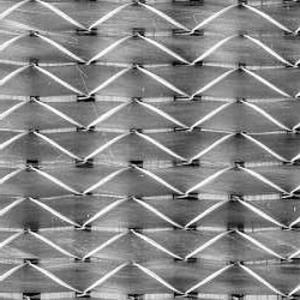

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

What are some common challenges in working with fiberglass?

Some common challenges in working with fiberglass include proper handling and disposal of the material, the need for protective equipment to avoid skin and respiratory issues, the risk of cuts and abrasions from sharp edges, the difficulty of achieving a smooth finish, and the potential for allergic reactions to the resin used in fiberglass production.

What are the different types of fiberglass reinforcements for electrical applications?

The different types of fiberglass reinforcements for electrical applications include E-glass, S-glass, and C-glass. E-glass is the most commonly used and offers good electrical insulation properties. S-glass is stronger and stiffer than E-glass, making it suitable for applications requiring higher mechanical strength. C-glass is known for its good resistance to chemicals and corrosion, making it a preferred choice for harsh environments.

How do you reinforce automotive parts with fiberglass materials?

To reinforce automotive parts with fiberglass materials, the first step is to prepare the surface by cleaning and sanding it. Next, a layer of fiberglass cloth or mat is applied onto the part, ensuring it is properly aligned and fitted. A resin mixture, typically epoxy, is then applied to saturate the fiberglass and bond it to the part. This process may be repeated with additional layers to enhance strength and durability. Once the resin cures, the part can be sanded, primed, and painted if desired.

How is fiberglass used in the production of electrical enclosures?

Fiberglass is commonly used in the production of electrical enclosures due to its excellent insulation properties. It is used to line the inside of the enclosure, providing a protective barrier between the electrical components and the external environment. Fiberglass also helps to prevent the transfer of heat, moisture, and dust, ensuring the safe operation and longevity of the electrical equipment inside the enclosure. Additionally, fiberglass is lightweight and corrosion-resistant, making it a durable and cost-effective material choice for manufacturing electrical enclosures.

How does fiberglass supply handle vibrations or impacts?

Fiberglass supply is known for its excellent ability to handle vibrations or impacts. This is due to its unique composition, which is made up of reinforced fibers embedded in a resin matrix. These fibers provide strength and flexibility to the material, allowing it to absorb and disperse vibrations or impacts effectively. Additionally, fiberglass has a high strength-to-weight ratio, making it exceptionally durable and resistant to damage. Overall, fiberglass supply is a reliable choice for applications where vibration or impact resistance is crucial.

Wholesale Fiberglass Supply from supplier in Bolivia

Whether you are in need of fiberglass materials for construction, insulation, or any other application, we have the products to meet your requirements. Our range includes fiberglass sheets, panels, rods, tubes, and custom-made products that can be tailored to your specific needs.

At our company, we understand the importance of timely and efficient service. Our dedicated team is committed to providing you with prompt and reliable sales assistance. We can provide you with detailed quotations, ensuring that you receive competitive pricing for your fiberglass supply needs.

In addition to our sales services, we also offer comprehensive technical support. Our team of experts is well-versed in the technical aspects of fiberglass materials and can provide valuable advice and guidance. Whether you need assistance with product selection, installation, or troubleshooting, we are here to help.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a global network of resources. This enables us to source high-quality fiberglass materials from reliable suppliers, ensuring that you receive products of the highest standards.

Our experience in the Bolivian market sets us apart from other suppliers. We understand the unique challenges and requirements of the local industry and can provide you with tailored solutions. Our team has built strong relationships with local contractors, architects, and engineers, allowing us to offer valuable insights and expertise to support your projects.

In summary, when it comes to fiberglass supply in Bolivia, we are the leading choice. With our comprehensive range of products, prompt sales assistance, technical support, and industry expertise, we can fulfill all your fiberglass procurement needs. Contact us today to discuss your requirements and discover how we can add value to your projects.

At our company, we understand the importance of timely and efficient service. Our dedicated team is committed to providing you with prompt and reliable sales assistance. We can provide you with detailed quotations, ensuring that you receive competitive pricing for your fiberglass supply needs.

In addition to our sales services, we also offer comprehensive technical support. Our team of experts is well-versed in the technical aspects of fiberglass materials and can provide valuable advice and guidance. Whether you need assistance with product selection, installation, or troubleshooting, we are here to help.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a global network of resources. This enables us to source high-quality fiberglass materials from reliable suppliers, ensuring that you receive products of the highest standards.

Our experience in the Bolivian market sets us apart from other suppliers. We understand the unique challenges and requirements of the local industry and can provide you with tailored solutions. Our team has built strong relationships with local contractors, architects, and engineers, allowing us to offer valuable insights and expertise to support your projects.

In summary, when it comes to fiberglass supply in Bolivia, we are the leading choice. With our comprehensive range of products, prompt sales assistance, technical support, and industry expertise, we can fulfill all your fiberglass procurement needs. Contact us today to discuss your requirements and discover how we can add value to your projects.

Hot Search

- Fiberglass Chopped Strand in Finland

- Fiberglass Mesh Cloth in Fiji

- Composite Pipes in Vietnam

- FRP Pultrusion Profiles in Canada

- Fiberglass Mat Tissue in Benin

- Fiberglass Fabrics in Estonia

- Fiberglass Mesh in Guatemala

- Composite Tank in United Arab Emirates

- Fiberglass Mesh tape in Moldova

- Polymer in Indonesia