316l Stainless Steel

316l Stainless Steel Related Searches

Stainless Steel 316l Stainless Steel 316 316ti Stainless Steel 316 Grade Stainless Steel Type 316 Stainless Steel 304l Stainless Steel 316 Stainless Steel Sheet 316 Stainless Steel Tubing 316 Stainless Steel Rod Density Of 316 Stainless Steel 316 Stainless Steel Price 316 Stainless Steel Density 316l Stainless Steel Properties Density Of Stainless Steel 316 304 Or 316 Stainless Steel 316 Stainless Steel Hardness 316 Stainless Steel Composition 305 Stainless Steel 310 Stainless Steel 300 Stainless Steel 316 Stainless Steel Properties 304 Grade Stainless Steel Type 304 Stainless Steel Grade 304 Stainless Steel 330 Stainless Steel 301 Stainless Steel 3 16 Stainless Steel 300 Series Stainless Steel Stainless Steel 303 317 Stainless Steel316l Stainless Steel Supplier & Manufacturer from China

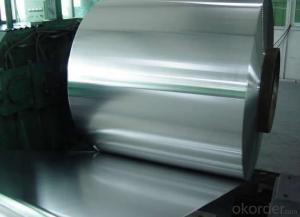

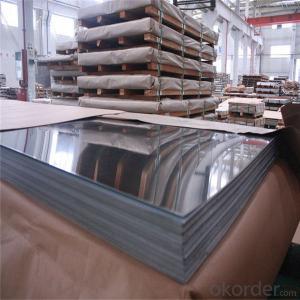

316L Stainless Steel is a type of austenitic stainless steel that contains a higher amount of nickel and molybdenum compared to the standard 304 stainless steel. It is widely recognized for its excellent corrosion resistance, particularly in marine environments and chemical processing applications. This grade of stainless steel is non-magnetic and provides superior strength and durability, making it a popular choice for various industries.The 316L Stainless Steel is extensively used in a variety of applications, including food processing equipment, pharmaceutical machinery, paper and pulp production, and heat exchangers. Its exceptional resistance to corrosion and pitting, along with its ability to withstand high temperatures, makes it ideal for use in demanding environments where other materials may fail. Additionally, 316L Stainless Steel is often specified for use in the manufacturing of marine hardware, chemical tankers, and offshore drilling platforms due to its outstanding performance in saltwater conditions.

Okorder.com is a leading wholesale supplier of 316L Stainless Steel, offering a vast inventory of this high-quality material. With a commitment to providing top-notch products and exceptional customer service, Okorder.com ensures that customers receive the best value for their investment. By partnering with reputable manufacturers, Okorder.com is able to deliver 316L Stainless Steel products that meet the highest industry standards, making it a reliable choice for businesses in need of durable and reliable materials.

Hot Products