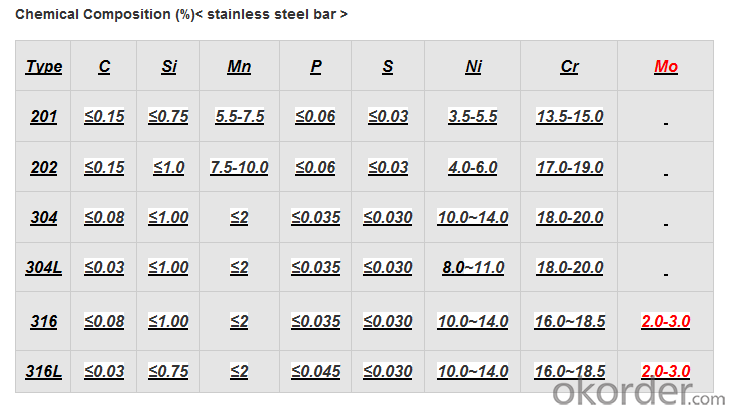

201 304 304L 316 316L Stainless Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

201 304 304L 316 316L Stainless Steel Bar

Product information:

Product show

Workshop show

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: Can special steel be used in marine environments?

- Indeed, marine environments can benefit from the utilization of special steel. Specifically engineered to endure the harsh conditions prevalent in marine settings, special steel, such as stainless steel or marine-grade steel, proves its worth. These environments typically expose materials to saltwater, which possesses a highly corrosive nature. Nonetheless, special steel's resistance to corrosion remains intact due to its elevated levels of chromium and other alloying elements. Consequently, it becomes exceedingly suitable for an array of marine applications, encompassing shipbuilding, offshore structures, and marine equipment. The reliability of special steel lies in its exceptional strength, durability, and corrosion resistance. Moreover, to further augment its resistance to corrosion, special steel can undergo additional treatment and coating, thereby guaranteeing its longevity and optimal performance in marine conditions.

- Q: What are the different special steel products available in the market?

- There are a wide variety of special steel products available in the market, each designed to meet specific industrial needs. Some of the common special steel products include: 1. Stainless Steel: This is a corrosion-resistant steel alloy that contains a minimum of 10.5% chromium. It is widely used in applications that require high resistance to corrosion, such as kitchen utensils, medical instruments, and chemical processing equipment. 2. Tool Steel: Tool steel is a type of carbon and alloy steel that is specifically designed to be used in the manufacturing of tools. It is known for its high hardness, resistance to abrasion, and ability to retain sharp edges. Tool steel is commonly used in the production of cutting tools, dies, and molds. 3. Alloy Steel: Alloy steel is a steel that has been alloyed with other elements, such as manganese, silicon, nickel, or chromium, to enhance its mechanical properties. It offers improved strength, toughness, and wear resistance compared to carbon steel. Alloy steel is used in various applications, including automotive components, construction equipment, and machinery parts. 4. High-Speed Steel: High-speed steel is a type of tool steel that is capable of cutting at high speeds without losing its hardness or ability to retain sharp edges. It is commonly used in the production of drills, milling cutters, and saw blades. 5. Spring Steel: Spring steel is a low-alloy, medium or high carbon steel that is known for its ability to retain its shape and elasticity even under high stress or repeated loadings. It is widely used in the manufacturing of springs, suspension systems, and shock absorbers. 6. Electrical Steel: Electrical steel, also known as silicon steel, is a specialized steel alloy that exhibits low electrical losses and high magnetic permeability. It is used in the production of electrical transformers, motors, and generators. 7. Heat-Resistant Steel: Heat-resistant steel is designed to withstand high temperatures without losing its mechanical properties. It is commonly used in applications such as furnaces, heat exchangers, and gas turbines. These are just a few examples of special steel products available in the market. The choice of steel product depends on the specific requirements of the application, including factors such as corrosion resistance, strength, hardness, and heat resistance.

- Q: How does special steel perform in terms of corrosion resistance?

- Special steel performs exceptionally well in terms of corrosion resistance. It is specifically designed and engineered to have enhanced resistance against corrosion compared to standard steel. This is achieved through various alloying elements and specific heat treatment processes that create a protective barrier against corrosive elements such as moisture, chemicals, and atmospheric conditions. As a result, special steel exhibits excellent durability and longevity even in corrosive environments, making it a preferred choice in industries where corrosion resistance is crucial, such as marine, oil and gas, and chemical industries.

- Q: What are the different corrosion protection techniques used for special steel?

- There are several corrosion protection techniques used for special steel, including: 1. Coating: Applying a protective layer of paint, powder coating, or other chemical coatings helps create a barrier between the steel and the corrosive elements in the environment. 2. Galvanization: Immersing the steel in molten zinc creates a protective coating that prevents corrosion by sacrificing itself to protect the steel underneath. 3. Cathodic protection: This technique involves connecting the steel to a sacrificial anode made of a more reactive metal, such as zinc or magnesium. The anode corrodes instead of the steel, providing protection. 4. Passivation: Treating the steel with chemicals or an oxidizing agent forms a thin, passive layer on the surface, which helps prevent further corrosion. 5. Alloying: Adding specific alloying elements, such as chromium or nickel, to the steel composition can enhance its corrosion resistance properties. 6. Barrier protection: Using barriers like plastic coatings or rubber linings can physically isolate the steel from the corrosive environment, preventing direct contact and corrosion. 7. VCI (Volatile Corrosion Inhibitor): Packaging the steel in a material that releases special compounds, such as VCI paper or film, can create a protective atmosphere around the steel, inhibiting corrosion. These techniques can be used individually or in combination to provide effective corrosion protection for special steel, depending on the specific requirements and the environment in which the steel is exposed.

- Q: How does special steel perform in casting applications?

- Due to its unique properties and characteristics, special steel demonstrates exceptional performance in casting applications. Firstly, its excellent heat resistance enables it to withstand high temperatures during the casting process, ensuring that it maintains its shape and strength. Additionally, special steel possesses remarkable strength and toughness, guaranteeing that the final cast product will be durable and strong. Moreover, its superior corrosion resistance ensures that the castings remain intact and functional even in harsh environments. Furthermore, special steel's high wear resistance minimizes material loss and extends the lifespan of the castings. Lastly, its excellent machinability allows for precise shaping, cutting, and finishing during the casting process. In conclusion, special steel's exceptional heat resistance, strength, corrosion resistance, wear resistance, and machinability make it an ideal choice for casting applications, ensuring the production of high-quality and reliable castings.

- Q: How does special steel contribute to the metalworking industry?

- Special steel contributes to the metalworking industry by offering enhanced properties such as increased strength, durability, and resistance to corrosion or heat. These unique characteristics make it suitable for a wide range of applications, including manufacturing of machinery, tools, and components used in various sectors like automotive, aerospace, construction, and energy. By providing superior performance and reliability, special steel helps improve productivity, efficiency, and safety in metalworking processes, ultimately driving innovation and advancement in the industry.

- Q: Can special steel be recycled?

- Yes, special steel can be recycled.

- Q: What are the different methods for annealing special steel?

- There are several methods for annealing special steel, including full annealing, process annealing, stress relief annealing, and spheroidizing annealing. Full annealing involves heating the steel to a temperature above the critical range and then slowly cooling it to room temperature. Process annealing is used to improve machinability and involves heating the steel to a temperature below the critical range and then cooling it in still air. Stress relief annealing is carried out to reduce internal stresses in the steel by heating it to a temperature below the critical range and then cooling it slowly. Spheroidizing annealing is used to improve the steel's formability and involves heating it to a temperature below the critical range and then cooling it slowly. Each method has its own specific purpose and benefits for annealing special steel.

- Q: How is special steel stored and transported?

- Special steel is typically stored and transported in a controlled environment to ensure its quality and prevent any damage or contamination. It is stored in covered warehouses or facilities equipped with proper ventilation, humidity control, and temperature regulation. Additionally, special steel is often stored on racks or shelves to prevent direct contact with the ground and minimize the risk of corrosion. When it comes to transportation, special steel is usually transported in specially designed containers or crates, ensuring protection from external elements and providing secure handling during transit.

- Q: Can special steel be heat treated?

- Yes, special steel can be heat treated. Heat treatment is a process used to alter the physical and mechanical properties of steel by heating it to specific temperatures and then cooling it at controlled rates. This treatment allows for the adjustment of hardness, strength, toughness, and other desired characteristics in special steel.

Send your message to us

201 304 304L 316 316L Stainless Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords