201/304/316/304L/316L/309S/310S/430 stainless steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

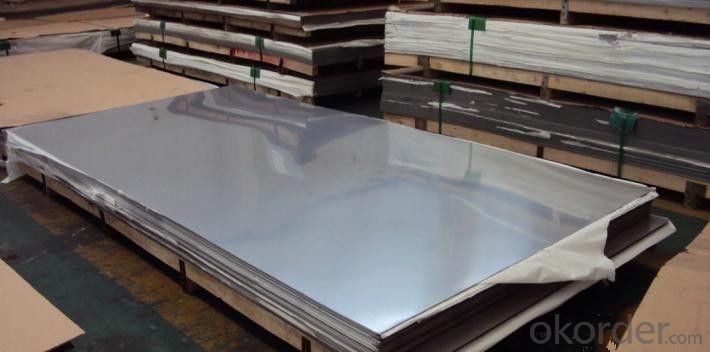

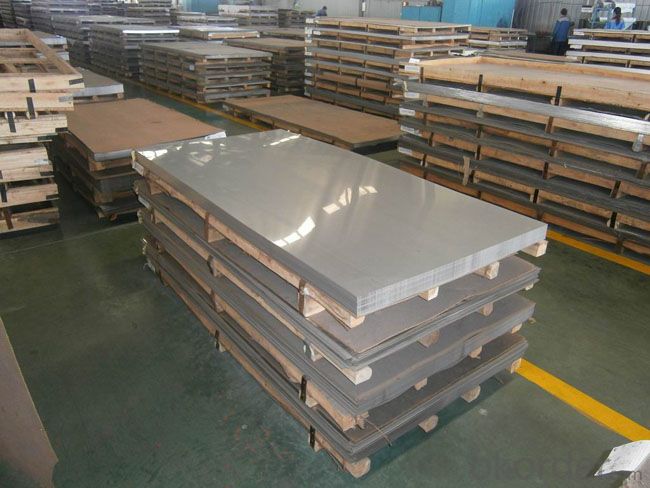

Stainless Steel Sheet

Quick Details:

Specifications of Stainless Steel Sheets:

1. Material: 200series&300series&400series

2. Standard: JIS, AISI, ASTM, GB, DIN, EN

3. Thickness: 0.3-100mm or as customer’s requirement

4. Width: 1500-2200mm or as customer’s requirement

5. Length: 1000-6000mm or as customer’s requirement

6. Surface: 2B, BA, No.1, etc

7. Technical processing: Hot Rolled/Cold Rolled

8. Decorative:

Mirror, No.4, HL NSP, Bead Blast, Vibration,

HL Gold, Mirror Gold, Vibration Gold NSP,

No4 Copper NSP, Mirror Copper, Bead Copper,

HL Brass, Mirror Brass, Bead Brass,

HL Black, Mirror Black, Bead Black NSP,

HL Bronz, Mirror Bronze, Vibration Bronze,

Mirror Etched, HL Etched Copper, Mirror Black Etched, Mirror Etched Gold.

Features of 304 Stainless Steel Sheet/pipe/bar:

Accurate dimension

Minimum maintenance

Excellent service life

Non Corrosive

Heat Resistant

chemical composition

C: ≤ 0.08 Mn: ≤ 2.00 Si: ≤ 1.50 Cr: 24.0 ~ 26.0 Ni : 19.0 ~ 22.0 P: ≤ 0.045 S: ≤ 0.03

Article | SS 201/304/316/304L/316L/309S/310S/430 stainless steel |

specification | T(0.3-3mm)*W(30-3000mm)*sheet |

Surface | 2B |

type | Sheet |

Standard | ASTM JIS EN GB |

Usage | construction field, ships building industry, petroleum, chemical industries, war and electricity industries, food processing and medical industry, boiler heat Exchanger, machinery and hardware fields |

Parking | Standard export packing or according to your requirements/customized packing |

Payment | T/T, L/C at sight,Western Union,DP |

- Q: Can stainless steel bars be used in outdoor environments?

- Yes, stainless steel bars can be used in outdoor environments. Stainless steel is highly resistant to corrosion and rust, making it an ideal material for outdoor applications. It can withstand exposure to various weather conditions, moisture, and even saltwater without deteriorating. Additionally, stainless steel's strength and durability make it suitable for withstanding outdoor elements and providing long-lasting performance.

- Q: What are the different specifications for stainless steel bars?

- There are several different specifications for stainless steel bars, which dictate their composition, dimensions, and mechanical properties. One of the most common specifications is the American Society for Testing and Materials (ASTM) standard, which provides guidelines for various grades of stainless steel bars. The ASTM A276 specification, for example, covers stainless steel bars and shapes for use in various structural and mechanical applications. It specifies the chemical composition, heat treatment, and mechanical properties of stainless steel bars. Another widely used specification is the American Iron and Steel Institute (AISI) standard. The AISI 304 and AISI 316 grades are two of the most popular stainless steel grades used in bars. These grades are known for their excellent corrosion resistance and high strength. The dimensions and shapes of stainless steel bars are also specified according to standards. Common shapes include round bars, square bars, and hexagonal bars. The diameter or width and length of the bars are usually specified in millimeters or inches, depending on the standard used. In addition to ASTM and AISI standards, there are also international standards such as the European Norm (EN) and the Japanese Industrial Standards (JIS), which provide specifications for stainless steel bars. These standards may differ in terms of chemical composition, mechanical properties, and tolerances. Overall, the different specifications for stainless steel bars ensure that they meet specific requirements for various applications, such as construction, automotive, aerospace, and manufacturing industries. It is important to choose the right specification based on the intended use to ensure optimal performance and longevity of the stainless steel bars.

- Q: Do stainless steel bars require any protective coatings?

- No, stainless steel bars do not require any protective coatings. Stainless steel is known for its resistance to corrosion and rusting, making it highly durable and low-maintenance. The chromium content in stainless steel forms a passive oxide layer on the surface, which acts as a protective barrier against environmental elements. This layer continually reforms and protects the steel from corrosion. Hence, stainless steel bars can be used in various applications without the need for additional protective coatings.

- Q: Are stainless steel bars suitable for architectural facades?

- Yes, stainless steel bars are suitable for architectural facades. Stainless steel is a durable and corrosion-resistant material, making it ideal for external applications such as facades. It can withstand harsh weather conditions, UV radiation, and pollution, ensuring a long-lasting and low-maintenance solution for architectural projects. Additionally, stainless steel bars offer a sleek and modern aesthetic that can enhance the overall design of a building. They can be used in various configurations and finishes to create unique and visually appealing facades. Their versatility and strength make stainless steel bars a popular choice among architects and designers for both residential and commercial projects.

- Q: How are stainless steel bars manufactured?

- The production of stainless steel bars involves a process known as stainless steel bar manufacturing. This process encompasses various stages that guarantee the production of bars with exceptional quality and precision. To begin the manufacturing of stainless steel bars, raw materials are melted. Iron ore, chromium, nickel, and other elements are melted in an electric furnace to create stainless steel. This melting process yields a molten metal, which is then refined and controlled to achieve the desired composition and quality. Once the molten metal is refined, it is poured into molds to form long metal bars called billets. These billets are subsequently heated and subjected to hot rolling to reduce their thickness and shape them according to specific dimensions. During hot rolling, the billets are passed through a series of rollers that apply pressure to shape the metal bars and enhance their mechanical properties. After the hot rolling process, the stainless steel bars undergo heat treatment, which involves heating them to a specific temperature and then rapidly or slowly cooling them. This heat treatment process enhances the bars' hardness, strength, and other properties, ultimately ensuring the desired mechanical and metallurgical characteristics of the stainless steel bars. Following heat treatment, the bars undergo cold drawing or cold finishing. This process entails pulling the bars through a series of dies at room temperature to reduce their size, enhance their surface finish, and improve their dimensional accuracy. Cold drawing also increases the bars' strength and enhances their surface properties. Finally, the stainless steel bars are cut into the desired lengths and subjected to quality inspection. Additional processes such as straightening, polishing, or coating may be applied before the bars are deemed suitable for use in various industries and applications. In summary, the manufacturing of stainless steel bars involves a combination of melting, casting, hot rolling, heat treatment, cold drawing, and finishing processes. These meticulous steps ensure that the bars meet specific standards and requirements, resulting in the production of durable, corrosion-resistant, and high-quality stainless steel bars suitable for a wide range of applications.

- Q: What are the different methods of testing stainless steel bars?

- There are several methods of testing stainless steel bars to ensure their quality and performance. Some of the commonly used methods include: 1. Chemical composition analysis: This method involves analyzing the composition of the stainless steel bars to ensure that they meet the required specifications. It helps to determine the presence and percentage of different elements such as carbon, chromium, nickel, and molybdenum. 2. Mechanical testing: This method involves conducting various mechanical tests to evaluate the strength, hardness, and ductility of the stainless steel bars. Tests such as tensile strength, yield strength, elongation, and hardness testing are performed to ensure that the bars can withstand the intended applications. 3. Visual inspection: Visual inspection is a basic method of testing stainless steel bars. It involves examining the bars for any surface defects, such as cracks, pits, or scratches. Visual inspection helps to identify any visible imperfections that could affect the performance or appearance of the bars. 4. Non-destructive testing (NDT): NDT methods are used to assess the integrity of stainless steel bars without causing any damage. Techniques such as ultrasonic testing, magnetic particle testing, liquid penetrant testing, and eddy current testing are commonly used to detect any internal or surface defects in the bars. 5. Corrosion testing: Stainless steel is known for its corrosion resistance properties. Corrosion testing is performed to evaluate the resistance of the bars to various corrosive environments. Tests such as salt spray testing, pitting corrosion testing, and intergranular corrosion testing are used to assess the corrosion resistance of the stainless steel bars. 6. Dimensional inspection: This method involves checking the dimensions and tolerances of the stainless steel bars to ensure they meet the required specifications. It includes measuring the length, diameter, straightness, and surface finish of the bars using precision instruments. By utilizing these various testing methods, manufacturers and users can ensure that stainless steel bars are of high quality, meet the necessary specifications, and are suitable for their intended applications.

- Q: Are stainless steel bars resistant to sulfuric acid corrosion?

- Yes, stainless steel bars are generally resistant to sulfuric acid corrosion. Stainless steel contains chromium, which forms a passive oxide layer on the surface when exposed to oxygen. This oxide layer acts as a protective barrier, preventing sulfuric acid from coming into direct contact with the steel and causing corrosion. However, the resistance of stainless steel to sulfuric acid corrosion can vary depending on the grade of stainless steel and the concentration and temperature of the sulfuric acid. In highly concentrated and elevated temperature conditions, certain grades of stainless steel may experience corrosion. Therefore, it is important to consider the specific application and consult with a materials engineer or corrosion specialist to select the appropriate grade of stainless steel for resistance to sulfuric acid corrosion.

- Q: What are the different packaging options for stainless steel bars?

- The different packaging options for stainless steel bars can include wooden crates, cardboard boxes, plastic wrapping, or custom packaging based on the specific requirements of the customer or industry standards.

- Q: Are stainless steel bars suitable for architectural canopies?

- Yes, stainless steel bars are highly suitable for architectural canopies. Stainless steel is known for its durability, resistance to corrosion, and aesthetic appeal, making it an ideal material choice for architectural applications. Stainless steel bars can withstand various weather conditions, including rain, snow, and extreme temperatures, without rusting or deteriorating. Additionally, stainless steel bars can be easily fabricated into different shapes and sizes, allowing for the creation of intricate and visually appealing canopy designs. The sleek and modern look of stainless steel can enhance the overall architectural aesthetics of a structure, making it a popular choice for canopies in commercial, residential, and public spaces. Overall, stainless steel bars offer a combination of strength, durability, and aesthetics, making them highly suitable for architectural canopies.

- Q: Can stainless steel bars be used in aerospace applications?

- Indeed, aerospace applications can make use of stainless steel bars. Stainless steel, renowned for its versatility and durability, boasts remarkable resistance to corrosion and a commendable strength-to-weight ratio, rendering it a fitting choice for a myriad of aerospace components. Aircraft structures, engine parts, landing gear, and fasteners are among the numerous applications commonly employing stainless steel. Particularly, stainless steel bars frequently find utility in scenarios necessitating outstanding strength and durability, exemplified by their presence in wing spars, fuselage frames, and engine mounts. Moreover, stainless steel's ability to withstand high temperatures and extreme weather conditions further solidifies its status as a dependable option for aerospace applications.

Send your message to us

201/304/316/304L/316L/309S/310S/430 stainless steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords