cold rolled stainless steel round bar

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless Steel round Bar

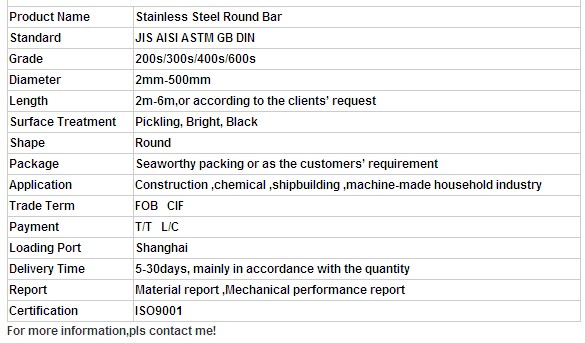

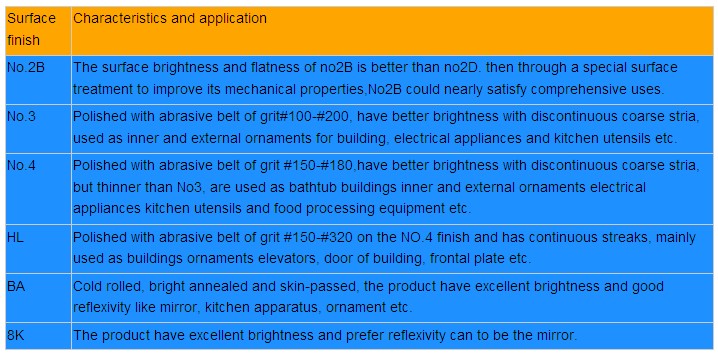

Specifications

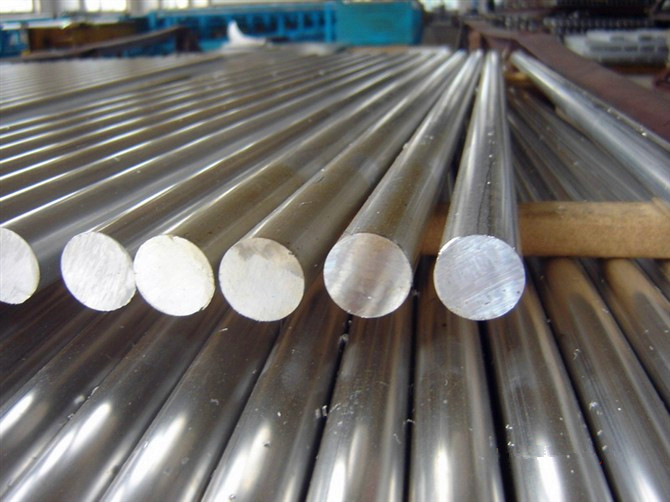

stainless steel round bar

1.Specification:12-300mm

2.Material:304 316

3.Length:standard 6m

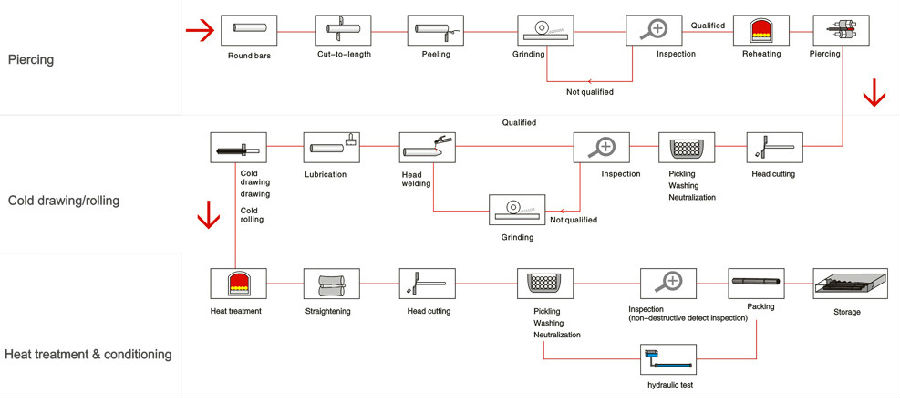

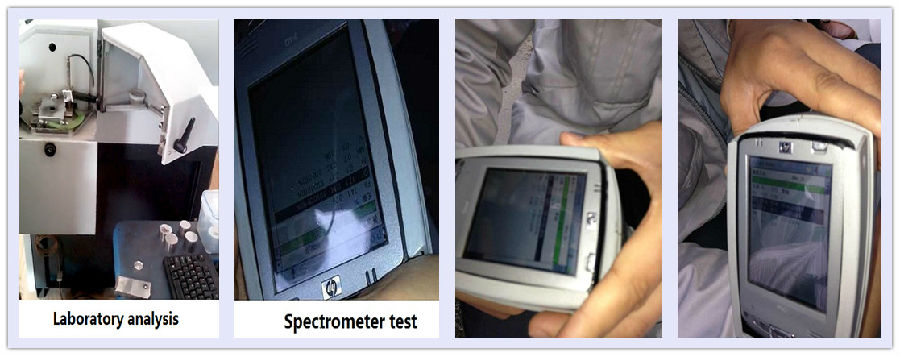

A series of pictures

- Q: Are stainless steel bars suitable for marine environments?

- Yes, stainless steel bars are suitable for marine environments. Stainless steel has excellent corrosion resistance properties, making it highly resistant to rust and other forms of corrosion caused by exposure to saltwater and moisture. This durability and resistance to corrosion make stainless steel bars an ideal choice for marine applications, as they can withstand the harsh conditions of the sea and maintain their strength and integrity over time.

- Q: Are stainless steel bars suitable for telecommunications equipment?

- Yes, stainless steel bars can be suitable for telecommunications equipment. Stainless steel has excellent corrosion resistance, which makes it ideal for environments where moisture or chemicals are present, such as telecommunications facilities. It also has high strength and durability, allowing it to withstand harsh conditions and vibrations that can occur in telecommunication installations. Additionally, stainless steel bars can be easily fabricated into various shapes and sizes, making them versatile for different equipment requirements. Overall, stainless steel bars provide a reliable and long-lasting solution for telecommunications equipment.

- Q: Can stainless steel bars be used in the manufacturing of storage tanks?

- Stainless steel bars are capable of being utilized in the production of storage tanks. Due to its exceptional corrosion resistance and durability, stainless steel is a favored option for storage tanks. When constructing the storage tank, stainless steel bars can serve as the foundation or structural elements, imparting strength and support. Moreover, the bars can be joined together through welding or bolting to create a secure and impervious storage tank. The high strength-to-weight ratio of stainless steel renders it an ideal material for storage tanks, enabling it to withstand substantial loads and pressure. Furthermore, stainless steel exhibits resistance to a variety of chemicals and substances, thereby making it suitable for storing a diverse range of liquids, gases, and hazardous materials. All in all, when it comes to the manufacturing of storage tanks, stainless steel bars are both dependable and efficacious.

- Q: What is the thermal expansion coefficient of stainless steel bars?

- The thermal expansion coefficient of stainless steel bars varies depending on the specific grade of stainless steel. In general, stainless steel exhibits a lower thermal expansion coefficient compared to metals like aluminum or copper. The coefficient of thermal expansion for stainless steel falls within the range of 9 to 16 × 10^-6 per °C (or 9 to 16 μm/m·°C). It should be noted that the coefficients of different grades of stainless steel differ slightly due to variations in their chemical composition and microstructure. The precise thermal expansion coefficient of stainless steel bars used in production depends on the specific grade employed. Understanding the thermal expansion coefficient is crucial when considering the impact of temperature changes on stainless steel bars. As the temperature rises or falls, stainless steel bars will expand or contract accordingly. This information is vital for the design of structures, machinery, or components that may be exposed to varying temperatures. It ensures a proper fit and prevents potential issues arising from thermal expansion or contraction.

- Q: Are stainless steel bars suitable for the production of cutting tools?

- Yes, stainless steel bars are suitable for the production of cutting tools. Stainless steel is known for its excellent corrosion resistance, durability, and strength. These properties make stainless steel bars ideal for manufacturing cutting tools that need to withstand the harsh conditions of cutting and shaping various materials. Stainless steel bars can be easily machined and hardened, allowing for the production of sharp and long-lasting cutting edges. Additionally, stainless steel's resistance to staining and rusting ensures that the cutting tools remain in good condition even when exposed to moisture or corrosive substances. Overall, stainless steel bars provide the necessary properties to create high-quality cutting tools that can effectively and efficiently perform their intended tasks.

- Q: How do you determine the size and length of a stainless steel bar?

- To determine the size and length of a stainless steel bar, you would typically refer to the product specifications provided by the manufacturer or supplier. These specifications usually include details such as diameter or width, length, and sometimes even weight. Additionally, you can use measuring tools like calipers or a tape measure to physically measure the bar's dimensions.

- Q: Can stainless steel bars be used in the electronics industry?

- Yes, stainless steel bars can be used in the electronics industry. Stainless steel is often used for components and fixtures in electronic devices due to its excellent corrosion resistance, high strength, and heat resistance. It can be used for manufacturing connectors, housings, brackets, and other parts that require durability and reliability in electronic applications.

- Q: What is the corrosion resistance of stainless steel bars in acidic environments?

- Stainless steel bars generally have good corrosion resistance in acidic environments due to the high levels of chromium present in the alloy. The chromium forms a protective oxide layer on the surface of the steel, which helps prevent corrosion. However, the exact level of corrosion resistance can vary depending on the specific grade of stainless steel and the concentration and type of acid present in the environment.

- Q: Can stainless steel bars be used in the pharmaceutical industry?

- Yes, stainless steel bars can be used in the pharmaceutical industry. Stainless steel is known for its corrosion resistance, durability, and ease of cleaning, making it a suitable material for pharmaceutical equipment and fixtures. It is often used in the manufacturing of storage tanks, mixing vessels, piping systems, and other pharmaceutical process equipment.

- Q: Do stainless steel bars have good resistance to pitting?

- Stainless steel bars exhibit exceptional resistance to pitting, a specific type of corrosion that arises when the protective passive layer on the stainless steel surface is compromised. Nevertheless, stainless steel possesses chromium, which generates a thin layer of oxide that acts as a shield against corrosion and pitting. This protective layer has the ability to self-repair, swiftly reforming if damaged and ensuring continuous protection against pitting. Furthermore, stainless steel can be combined with other elements like molybdenum and nickel to further amplify its resistance to pitting and various other forms of corrosion. Consequently, stainless steel bars demonstrate remarkable resistance to pitting and are widely utilized in corrosive environments where alternative metals would prove inadequate.

Send your message to us

cold rolled stainless steel round bar

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords