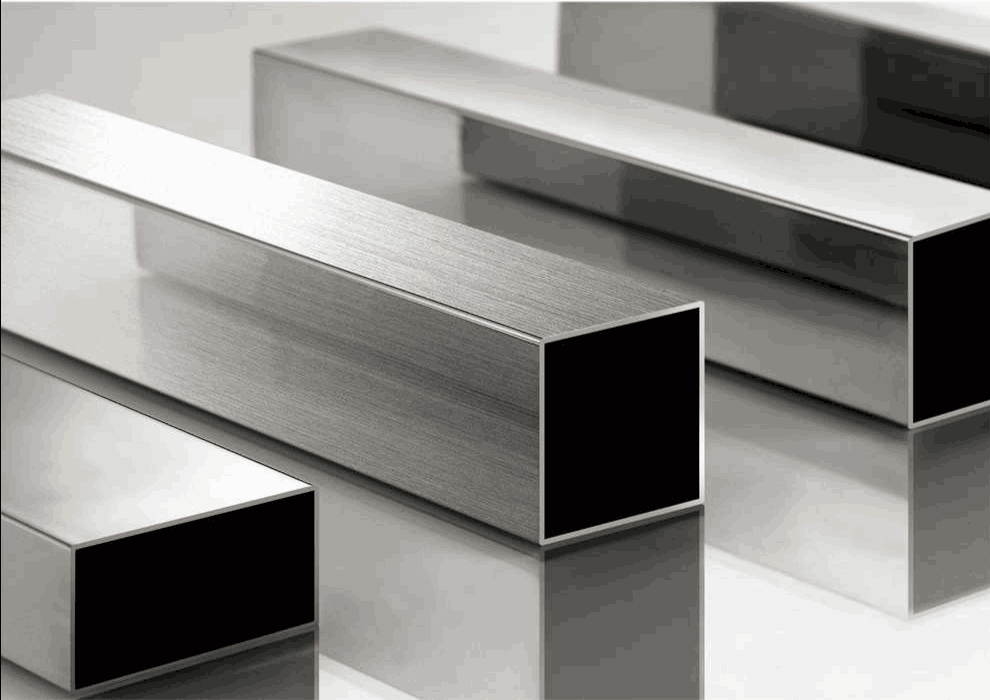

Stainless Steel Pipe Manufacturers in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

stainless steel pipe manufacturers

Material | 304:0cr18ni9, 0cr17ni8 201:1cr17mn6ni5n,1cr13mn9ni1n 316:0cr17ni12 or as customer’s request |

Size(round pipe) | 9.5, 12.7, 15.9, 17, 18, 19.1, 20, 21, 22.2, 23, 25.4, 28, 318, 35, 60, 63.5, 73, 76.2, 88.9, 101.6, 114.3, 127, 133, 59, 168, 219 mm or customized |

Size (square pipe) | 10×10,12×12,18×18,23×23,38×38,50×50,70×70,100×100,20×10,23×10,24×12,25×13,36×23, 40×20,50×20,60×15,75×45,80×60,95×45,100×60,150×100 mm or customized |

Size (oval pipe) | 30×15,80×40 mm os customized |

Thickness | 0.24-3 mm |

Length | 6m or according to customer’s request |

Outer diameter | 6.35-219mm |

Tolerance | Outer diameter :±0.2mm |

Thickness :±0.02mm | |

Length :±0.5mm | |

Process method | Code drawn, annealed with nitrogen protection, ultrasonic,automatic shape, polished |

Finishing | A: sanded B: 400#-600# mirror C: hairline brushed D: TIN titanlum E : HL brushed & mirror (two kinds of finishing for one pipe) |

Chemical Composition | |||||||

Material | C | Si | Mn | P | S | Cr | Ni |

201 | ≤0.12 | ≤0.75 | 9.5-12.5 | ≤0.045 | ≤0.03 | 13-16 | 0.8-1.5 |

304 | ≤0.08 | ≤0.75 | ≤2.0 | ≤0.045 | ≤0.03 | 18-19 | 8-10 |

316 | ≤0.08 | ≤1.00 | ≤2.0 | ≤0.035 | ≤0.03 | 10-14 | 16.0-18.5 |

430 | ≤0.12 | ≤0.75 | ≤2.0 | ≤0.04 | ≤0.03 | 16-18 | ≤0.6 |

Square pipe and rectangle pipe

round pipe

PACK & DELIVERY

Packaging & Delivery of stainless steel pipe manufacturers

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

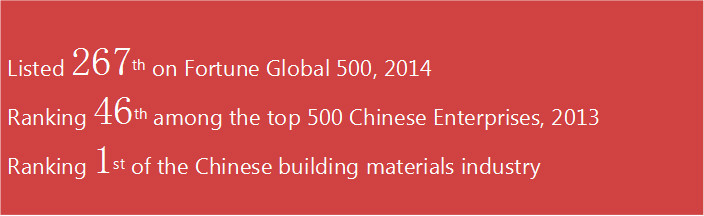

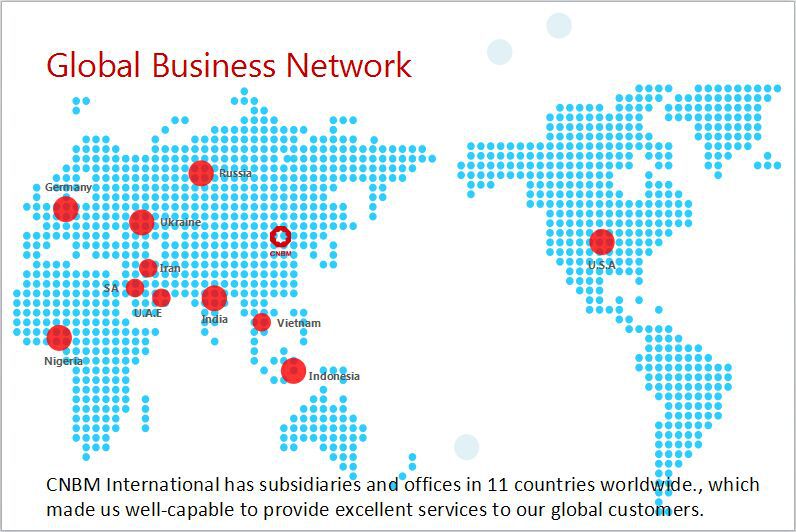

COMPANY INFORMATION

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

Client

Export Markets Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

F A Q

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories

- Q: Are stainless steel bars resistant to abrasion?

- Yes, stainless steel bars are highly resistant to abrasion.

- Q: Can stainless steel bars be etched or engraved?

- Yes, stainless steel bars can be etched or engraved using various techniques such as chemical etching or laser engraving.

- Q: How do you clean and maintain stainless steel bars?

- To clean and maintain stainless steel bars, you can follow these steps: 1. Start by removing any loose dirt or debris from the surface of the bars using a soft cloth or a brush. This will help prevent scratching during the cleaning process. 2. Prepare a cleaning solution by mixing warm water with a mild detergent or dish soap. Avoid using abrasive cleaners or harsh chemicals as they can damage the stainless steel finish. 3. Dip a soft cloth or sponge into the cleaning solution and gently scrub the stainless steel bars in the direction of the grain. This will help prevent scratching and maintain the appearance of the bars. 4. Pay special attention to any stubborn stains or marks. You can use a non-abrasive scrubbing pad or a soft-bristle brush to gently remove these without causing any damage. 5. Rinse the bars thoroughly with clean water to remove any soap residue. Ensure all cleaning solution is completely removed from the surface. 6. Dry the stainless steel bars with a soft, clean cloth to prevent water spots or streaks. Make sure the bars are completely dry before proceeding to the next step. 7. To maintain the shine and protect the stainless steel, you can apply a stainless steel cleaner or polish. Follow the manufacturer's instructions on the product and apply it using a clean cloth or sponge, rubbing in the direction of the grain. 8. Wipe off any excess cleaner or polish with a separate clean cloth, again following the grain of the stainless steel. 9. For regular maintenance, you can simply wipe down the stainless steel bars with a damp cloth or sponge to remove any surface dust or fingerprints. 10. Avoid using abrasive materials, steel wool, or harsh chemicals on stainless steel bars as they can scratch or damage the surface. By following these steps, you can effectively clean and maintain the appearance of your stainless steel bars, keeping them looking shiny and pristine for years to come.

- Q: Can stainless steel bars be used in nuclear power plants?

- Yes, stainless steel bars can be used in nuclear power plants. Stainless steel is widely used in the construction of nuclear power plants due to its excellent corrosion resistance, high strength, and heat resistance properties. It is commonly used for various applications, including structural components, fuel storage containers, and piping systems within the nuclear facilities. Stainless steel's ability to withstand harsh radioactive environments and its resistance to corrosion make it a suitable material for ensuring the safety and long-term durability of nuclear power plants.

- Q: Do stainless steel bars have good heat resistance?

- Yes, stainless steel bars have good heat resistance. Stainless steel is known for its high resistance to heat and corrosion, making it suitable for various applications in different industries. The addition of chromium and other alloying elements in stainless steel enhances its heat resistance properties. It can withstand high temperatures without losing its strength or undergoing significant deformation. Stainless steel bars are often used in heat exchangers, pressure vessels, and other high-temperature environments where excellent heat resistance is required. Additionally, stainless steel's heat resistance makes it a popular choice for kitchen appliances and cookware, as it can endure high cooking temperatures without warping or corroding.

- Q: Are stainless steel bars suitable for the dairy industry?

- Yes, stainless steel bars are suitable for the dairy industry. Stainless steel is a corrosion-resistant material that is easy to clean and maintain, making it ideal for use in dairy processing equipment and facilities. It is also non-reactive with dairy products, ensuring the preservation of their quality and taste. Additionally, stainless steel has high strength and durability, allowing it to withstand the rigorous demands of the dairy industry.

- Q: What are the different types of stainless steel bars used in food packaging?

- Some of the different types of stainless steel bars used in food packaging include austenitic stainless steel bars (such as 304 and 316), ferritic stainless steel bars, and martensitic stainless steel bars. These bars are chosen for their corrosion resistance, durability, and hygienic properties, ensuring the safety and quality of food packaging materials.

- Q: Are stainless steel bars resistant to pitting?

- Yes, stainless steel bars are highly resistant to pitting. Pitting corrosion is a localized form of corrosion that occurs in metals, particularly in environments containing chloride ions. However, the addition of chromium to stainless steel creates a passive film on the surface, which acts as a protective barrier against corrosion. This passive film makes stainless steel bars highly resistant to pitting corrosion, even in aggressive environments. Additionally, stainless steel bars can be further enhanced with the addition of other alloying elements such as molybdenum, which improves their resistance to pitting and crevice corrosion. Overall, stainless steel bars are known for their exceptional resistance to pitting, making them a reliable choice for various applications in corrosive environments.

- Q: Is stainless steel heating rod containing nickel and chromium harmful to human body?

- In order to prevent nickel, chromium and other heavy metals harmful to the human body, the use of stainless steel products should pay attention to:(1) do not use stainless steel tableware for a long time to contain strong acid or strong alkali food, in order to prevent chromium, nickel and other metal elements dissolved.(2) do not use stainless steel utensils to torment Chinese medicine. Because Chinese medicine contains many alkaloids, organic acids and other ingredients, especially in heating conditions, it is difficult to avoid chemical reactions with it, and make drugs ineffective, and even produce more toxic chemicals.(3) do not use strong alkaline or strong oxidizing chemicals washing.

- Q: Are stainless steel bars suitable for the production of fasteners?

- Yes, stainless steel bars are suitable for the production of fasteners. Stainless steel is a durable and corrosion-resistant material that is commonly used in various industries, including automotive, construction, and manufacturing. The high strength and corrosion resistance of stainless steel make it an ideal choice for fasteners, as they need to withstand high levels of tension and exposure to various environmental conditions. Stainless steel fasteners are known for their ability to resist rust and corrosion, ensuring long-lasting performance and reliability. Additionally, stainless steel bars can be easily machined and formed into various shapes and sizes, allowing for the production of a wide range of fasteners to meet specific requirements. Overall, stainless steel bars are a suitable and popular choice for the production of fasteners due to their strength, corrosion resistance, and versatility.

Send your message to us

Stainless Steel Pipe Manufacturers in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords