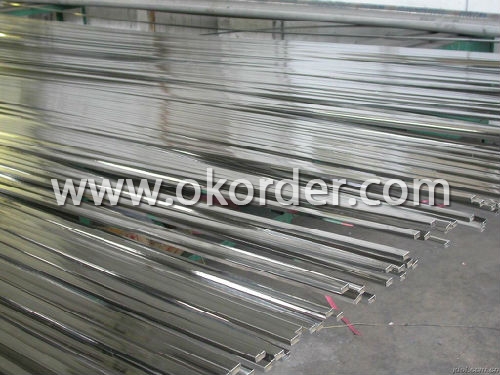

304 Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

304 Stainless Steel Flats

1.Standard:

AISI, GB, JIS, ASTM, DIN, EN

2. Grade:

1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:

3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application:

These products are widely supplied to areas of machine made industry, chemical industry, shipping industry,architecture, food industry, household products etc

Name | Stainless Steel Flat Bar | ||||||||

Material | 201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

Standard | JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

Length | 6m,5.8m,4m as required | ||||||||

Application | kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

Payment terms | L/C,T/T,Western Union,or as required. | ||||||||

MOQ | As required | ||||||||

Packing | Export standard package | ||||||||

Certificate | ISO/SGS | ||||||||

Contact | If you are interested in our products,please feel free to contact me. |

- Q: Are stainless steel pipes suitable for power plant systems?

- Stainless steel pipes prove to be a suitable option for power plant systems. Stainless steel is renowned for its exceptional ability to resist corrosion, a critical characteristic required in power plant systems. These systems expose pipes to elevated temperatures, pressures, and various corrosive elements like water, steam, and chemicals. The stainless steel pipes demonstrate remarkable resistance to rust, oxidation, and scaling, ensuring their reliability and durability over extended periods of time in power plant operations. Moreover, the stainless steel pipes possess considerable strength, enabling them to endure the high pressure and stress commonly encountered in power plant systems. Additionally, they exhibit outstanding heat resistance, a crucial feature given the extreme temperatures to which the pipes are exposed in power plants. In summary, due to their corrosion resistance, strength, and heat resistance properties, stainless steel pipes enjoy widespread popularity as a favored choice in power plant systems.

- Q: Can stainless steel pipes be used for cryogenic applications?

- Cryogenic applications can indeed utilize stainless steel pipes. Stainless steel is widely recognized for its exceptional properties at low temperatures, including admirable strength, flexibility, and resistance against corrosion. These qualities render stainless steel pipes suitable for the transportation and storage of cryogenic fluids, like liquid nitrogen, oxygen, or argon. The high strength-to-weight ratio of stainless steel permits the construction of lightweight and durable cryogenic systems. Furthermore, stainless steel pipes can endure the extreme temperature gradients and thermal stresses commonly encountered in cryogenic applications. Nevertheless, it is crucial to select the appropriate grade of stainless steel specifically engineered for cryogenic service to ensure optimal performance and safety.

- Q: Can stainless steel pipes be used in food processing plants?

- Yes, stainless steel pipes can be used in food processing plants. Stainless steel is a common choice in the industry due to its corrosion resistance, durability, and ability to withstand high temperatures. It does not react with food or contaminate it, making it a safe and hygienic option for transporting food and beverages in processing plants.

- Q: Are stainless steel pipes suitable for industrial water systems?

- Yes, stainless steel pipes are suitable for industrial water systems. Stainless steel is a highly durable and corrosion-resistant material, making it ideal for use in water systems that are exposed to harsh conditions and high levels of moisture. Stainless steel pipes have excellent resistance to both internal and external corrosion, which reduces the risk of leaks and contamination in industrial water systems. They also have a long lifespan and require minimal maintenance, resulting in cost-effectiveness in the long run. Additionally, stainless steel pipes have a high heat resistance, making them suitable for applications that involve hot water or steam. Overall, stainless steel pipes are a reliable and efficient choice for industrial water systems.

- Q: Stainless steel why rust?

- The surface of stainless steel deposited dust or heterogeneous metal particles containing other metal elements of the attachment, in the humid air, condensed water and adhesion between the stainless steel, the two together into a micro battery, causing the electrochemical reaction, the film has been destroyed, called electrochemical corrosion.

- Q: Are stainless steel pipes more expensive than other materials?

- Although stainless steel pipes tend to be more expensive compared to other materials, they offer significant advantages that justify their higher cost. Renowned for their exceptional durability, corrosion resistance, and longevity, stainless steel pipes can endure extreme temperatures, harsh chemicals, and high pressure, making them suitable for a wide range of applications like construction, plumbing, and industrial processes. Furthermore, stainless steel pipes necessitate minimal maintenance, providing long-term cost reductions. Despite the initial investment being higher, the superior performance and extended lifespan of stainless steel pipes render them a worthwhile choice in numerous scenarios. Ultimately, the decision to opt for stainless steel pipes should be based on the specific requirements and budget limitations of the project.

- Q: Can stainless steel pipes be used for geothermal systems?

- Indeed, geothermal systems can utilize stainless steel pipes. With its exceptional durability and resistance to corrosion, stainless steel proves itself as an ideal material for enduring the harsh conditions of such systems. Geothermal systems facilitate the transfer of heat from the earth's core to the surface, often necessitating the circulation of hot water or steam. In this regard, stainless steel pipes skillfully manage the elevated temperatures and pressure associated with geothermal systems, evading any corrosion or degradation over time. Furthermore, stainless steel possesses resistance against scaling and mineral accumulation, which are frequent occurrences in geothermal systems. As a result, employing stainless steel pipes guarantees the durability and efficiency of geothermal systems.

- Q: Can stainless steel pipes be bent or shaped?

- Yes, stainless steel pipes can be bent or shaped using various methods such as cold bending, hot bending, and tube bending machines.

- Q: Can stainless steel pipes be used for irrigation sprinkler systems?

- Indeed, irrigation sprinkler systems can utilize stainless steel pipes. Renowned for their durability, strength, and resistance to corrosion, stainless steel pipes prove to be an exceptional preference for irrigation setups. They possess the ability to endure high water pressure and are less prone to rust or decay over time in comparison to alternative materials, such as PVC or galvanized steel. Furthermore, stainless steel pipes guarantee hygienic conditions and do not taint the water supply, rendering them a secure choice for irrigation systems. Nevertheless, it remains crucial to take into account factors like cost and compatibility with existing infrastructure prior to opting for stainless steel pipes in irrigation sprinkler systems.

- Q: Can stainless steel pipes be used for solar energy systems?

- Yes, stainless steel pipes can be used for solar energy systems. Stainless steel is a versatile and durable material that can withstand the harsh conditions of solar energy systems. It is resistant to corrosion, which is crucial for the longevity of the pipes in outdoor and exposed environments. Stainless steel pipes also have excellent heat resistance properties, making them suitable for transporting hot fluids within solar energy systems. Additionally, stainless steel has a high strength-to-weight ratio, making it ideal for supporting the weight of solar panels or other components in the system. Overall, stainless steel pipes are a reliable and efficient choice for solar energy systems.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

304 Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords