seamless stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel pipe

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:60.3*3.91 mm or others

2.Surface: NO.1

3.Length:6m or as your requirement

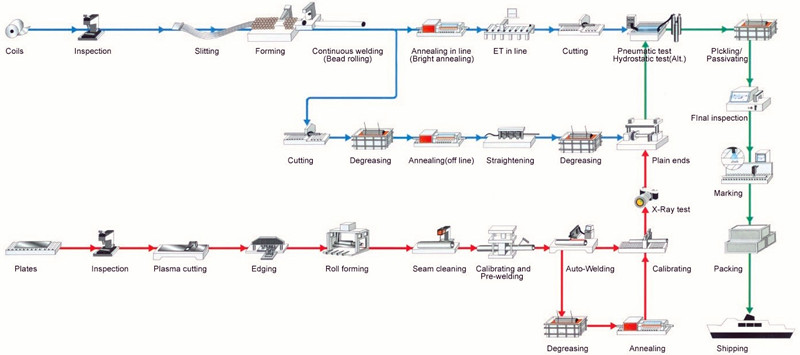

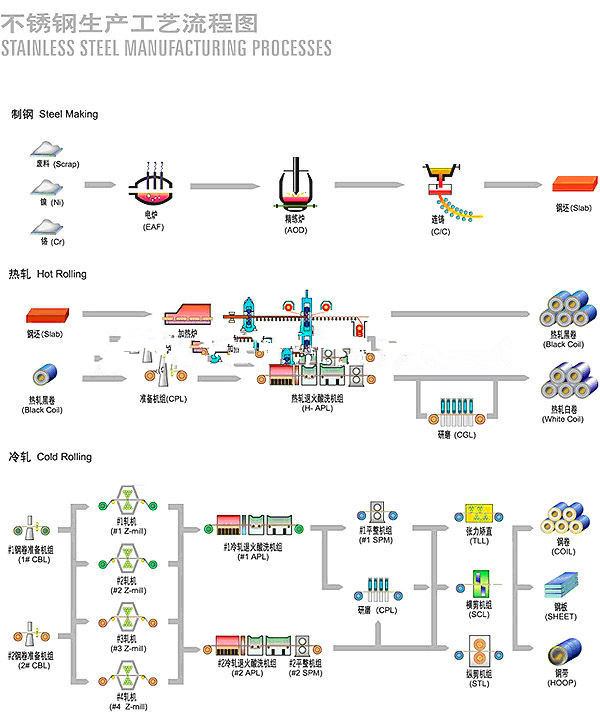

A series of photos

A series of pictures

- Q: Can stainless steel pipes be welded?

- Yes, stainless steel pipes can be welded.

- Q: How do you prevent clogging in stainless steel pipes?

- There are several steps that can be taken to prevent clogging in stainless steel pipes: 1. Regular maintenance is crucial. It is important to regularly inspect and clean the pipes to remove any build-up or debris that could cause blockages. 2. Proper waste disposal is essential. Only dispose of appropriate materials in the pipes and avoid flushing items like paper towels, sanitary products, or grease down the drain. These can accumulate and lead to clogs. 3. Install drain filters or strainers. These can catch large particles or debris that may cause clogs. Clean or replace them as needed. 4. Avoid corrosive materials. Certain chemicals or substances can corrode stainless steel pipes, leading to damage and potential clogs. Follow manufacturer guidelines and avoid using corrosive materials near the pipes. 5. Ensure proper water flow. Run water regularly, especially in pipes that are not frequently used, to maintain adequate water flow and prevent clogs. 6. Consider using water softeners. If your water supply is hard and contains minerals that can build up, installing a water softener can reduce mineral deposits and prevent clogs. 7. Seek professional assistance if needed. If you experience persistent clogging or are unsure about prevention methods, consult with a professional plumber. They can assess the situation, provide guidance, and effectively address any existing clogs. By following these preventive measures, you can minimize the risk of clogs in stainless steel pipes and maintain the efficient operation of your plumbing system.

- Q: Can stainless steel pipes be used for pulp and paper mills?

- Yes, stainless steel pipes can be used for pulp and paper mills. Stainless steel is highly resistant to corrosion and can withstand the harsh chemicals and high temperatures commonly found in pulp and paper mills. Additionally, stainless steel is durable and long-lasting, making it a suitable choice for such industrial applications.

- Q: How do you prevent pressure loss in stainless steel pipes?

- One way to prevent pressure loss in stainless steel pipes is to ensure proper installation and maintenance. This includes using high-quality fittings and connectors, following recommended guidelines for pipe sizing and support, and regularly inspecting and repairing any potential leaks or damages. Additionally, employing efficient flow control mechanisms such as valves and regulators can help minimize pressure loss in stainless steel pipes.

- Q: What's the easiest way to distinguish between stainless steel 202 and 304?

- 304 stainless steel performance is better than 202 stainless steel, the price is more expensive than 202 stainless steel.

- Q: Are stainless steel pipes more expensive than other types of pipes?

- Yes, stainless steel pipes are generally more expensive than other types of pipes. This is mainly due to the high cost of the raw materials used in the production of stainless steel, as well as the complex manufacturing processes involved. Stainless steel pipes also offer a range of advantages over other types of pipes, such as excellent resistance to corrosion, high durability, and the ability to withstand extreme temperatures. These factors contribute to their higher price point. However, the long-term benefits and superior performance of stainless steel pipes often justify the additional cost for many applications.

- Q: Can stainless steel pipes be used for steam applications?

- Indeed, stainless steel pipes have the capability to serve steam applications. Stainless steel possesses remarkable characteristics such as exceptional resistance to high temperatures and corrosion, rendering it appropriate for steam systems. It can endure the immense pressure and temperatures necessitated by steam applications without distorting or corroding. Moreover, stainless steel pipes exhibit durability and possess a lengthy lifespan, establishing them as a dependable option for steam applications. Furthermore, the ease of welding stainless steel pipes guarantees a secure and leakage-free steam system.

- Q: What is the maximum operating temperature for stainless steel pipes?

- The specific grade of stainless steel used can cause the maximum operating temperature for stainless steel pipes to vary. Nevertheless, stainless steel pipes, on the whole, can endure high temperatures. Typically, austenitic stainless steel grades like 304 and 316 are capable of handling temperatures up to 870°C (1600°F). Conversely, ferritic stainless steel grades like 430 have a lower maximum operating temperature of approximately 760°C (1400°F). To determine the precise maximum operating temperature for a specific stainless steel grade and pipe, it is crucial to refer to the manufacturer's specifications and guidelines.

- Q: What is the difference between electropolished and bright annealed stainless steel pipes?

- Electropolished stainless steel pipes undergo a process called electropolishing, which involves the removal of surface impurities and oxidation through an electrochemical process. This results in a smooth, shiny, and corrosion-resistant surface finish. On the other hand, bright annealed stainless steel pipes are heat-treated to achieve a bright, reflective surface finish. While both processes enhance the aesthetics of the pipes, electropolishing provides additional benefits such as improved cleanability and increased resistance to corrosion.

- Q: What is the external insulation used for stainless steel pipes?

- The external insulation used for stainless steel pipes is typically a heat-resistant material, such as fiberglass or mineral wool, which is applied to the outside of the pipe to prevent heat transfer and protect against corrosion.

Send your message to us

seamless stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords