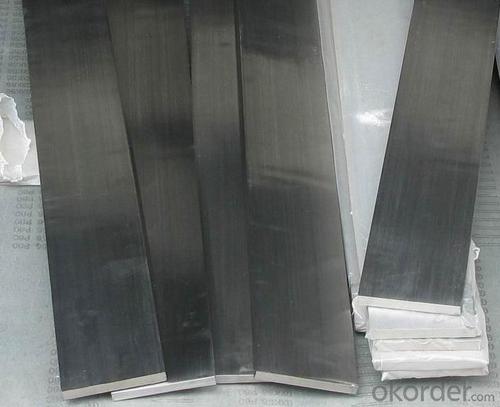

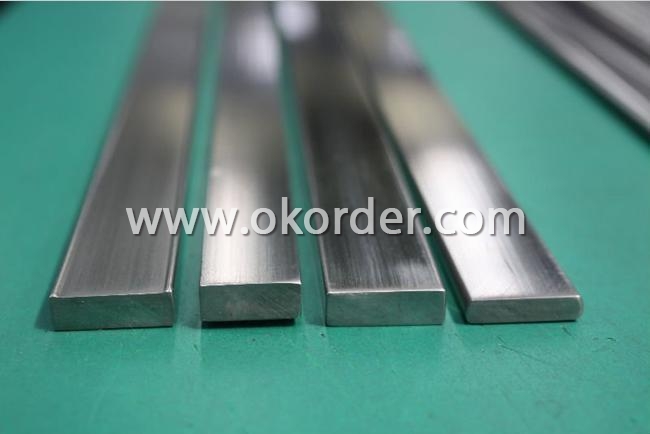

Stainless Steel Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 2200MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flat Bar

Details of Stainless Steel Flat Bar:

Thickness: 3mm - 15mm

Width: 25mm - 120mm

Inch Thickness: 1/8" - 5/8"mm

Width: 1" - 4.1/2"mm

Standard: ASTM A276/484M ,EN 10058/DIN 1017

Advantages of Stainless Steel Flat Bar :

1* All products are made of high quality material

2* More than 300 patterns

3* Favouable price&Considerable service

4* Fast delivery

5* Quickest and most efficient response to your inquiry

Specifications of Stainless Steel Flat Bar :

1. Prime stainless steel bar

2. Raw materials from TG

3. Independent factory

4. Deliverd within 3-7 days

5. Best service

- Q: Can stainless steel pipes be used for wastewater applications?

- Indeed, wastewater applications can utilize stainless steel pipes. The exceptional corrosion resistance of stainless steel enables it to endure the demanding conditions and chemicals commonly encountered in wastewater. Moreover, stainless steel exhibits durability and boasts an extensive lifespan, rendering it a fitting selection for managing wastewater. Furthermore, the smooth interiors of stainless steel pipes aid in averting obstructions and facilitating the efficient flow of wastewater. In addition, stainless steel contributes to environmental friendliness as it is entirely recyclable and causes minimal harm to the environment. In summary, stainless steel pipes represent a dependable and sustainable choice for wastewater applications.

- Q: Are stainless steel pipes suitable for water desalination plants?

- Yes, stainless steel pipes are suitable for water desalination plants. Stainless steel is highly resistant to corrosion, making it an ideal material choice for handling the high salinity levels in desalination plants. It offers excellent durability, longevity, and reliability in harsh environments, ensuring the efficient and safe transportation of water throughout the plant.

- Q: Can stainless steel pipes be used for food processing applications?

- Yes, stainless steel pipes can be used for food processing applications. Stainless steel is a preferred material in the food industry due to its excellent corrosion resistance, durability, and hygiene properties. It does not react with food or release any harmful substances, ensuring the safety and purity of the processed products. Stainless steel pipes are widely used in various food processing applications such as conveying liquids, gases, and solids, as well as for storing and transporting food products. They are easy to clean, maintain, and sanitize, making them suitable for meeting the strict hygiene standards required in the food industry. Additionally, stainless steel pipes can withstand high temperatures and pressures, making them suitable for various food processing processes.

- Q: Can stainless steel pipes be used for brewery and beverage industry applications?

- Yes, stainless steel pipes can be used for brewery and beverage industry applications. Stainless steel is highly resistant to corrosion, making it suitable for handling liquids and beverages. It is also easy to clean and maintain, ensuring the hygienic requirements of the industry are met. Stainless steel pipes are commonly used in these industries due to their durability, longevity, and compatibility with various fluids.

- Q: Are stainless steel pipes suitable for cryogenic applications?

- Stainless steel pipes are indeed suitable for cryogenic applications due to their exceptional low-temperature properties. This material proves to be an ideal choice when dealing with extremely cold temperatures in cryogenic applications. Its impressive strength, outstanding resistance to corrosion, and commendable thermal conductivity are all crucial factors when handling cryogenic fluids or gases. The structural integrity and durability of stainless steel pipes remain intact even under the harshest cold conditions, avoiding any brittleness. Moreover, the ability of stainless steel to resist expansion and contraction ensures consistent and dependable performance in cryogenic environments. Hence, it is no wonder that stainless steel pipes have gained popularity in various industries like aerospace, medical, and energy where cryogenic applications are commonly encountered.

- Q: Stainless steel why rust?

- Stainless steel surface adhesion contains acid, alkali and salt substances (such as decoration wall caustic soda, lime water splash), causing local corrosion.

- Q: Are stainless steel pipes resistant to scaling and oxidation?

- Yes, stainless steel pipes are highly resistant to scaling and oxidation. This is due to the presence of a protective layer of chromium oxide on the surface of stainless steel. This layer acts as a barrier, preventing the metal underneath from coming into contact with oxygen and other elements that may cause scaling and oxidation. As a result, stainless steel pipes are able to withstand high temperatures, corrosive environments, and frequent exposure to water without deteriorating or rusting. This makes them an excellent choice for various applications, such as in the construction, chemical, and food processing industries, where resistance to scaling and oxidation is crucial.

- Q: Can stainless steel pipes be insulated with polyethylene-co-vinyl acetate?

- Indeed, it is possible to insulate stainless steel pipes with polyethylene-co-vinyl acetate (PEVA). PEVA is widely utilized as an insulating substance owing to its remarkable thermal insulation characteristics. This material is both flexible and long-lasting, allowing for easy application to stainless steel pipes for insulation objectives. PEVA insulation contributes to the prevention of heat loss or gain, diminishes energy consumption, and furnishes protection against condensation. Furthermore, PEVA exhibits resistance against moisture, chemicals, and UV radiation, rendering it suitable for outdoor applications. Consequently, employing PEVA as insulation for stainless steel pipes presents a feasible alternative.

- Q: Can stainless steel pipes be used for architectural sculptures?

- Yes, stainless steel pipes can be used for architectural sculptures. Stainless steel is a versatile material that offers durability, corrosion resistance, and a sleek aesthetic. These qualities make it a popular choice for creating sculptures and structures in architectural projects. Stainless steel pipes can be manipulated into various shapes and sizes, allowing artists and architects to bring their creative visions to life. Additionally, stainless steel's ability to withstand harsh weather conditions and its low maintenance requirements make it suitable for outdoor installations. Overall, stainless steel pipes provide a reliable and visually appealing option for architectural sculptures.

- Q: Can stainless steel pipes be used for chemical processing applications?

- Yes, stainless steel pipes can be used for chemical processing applications. Stainless steel is highly resistant to corrosion and can withstand a wide range of chemicals and temperatures, making it an ideal choice for chemical processing industries. Its durability, strength, and ability to maintain product purity make stainless steel pipes suitable for various chemical processes such as manufacturing, transportation, and storage of chemicals.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 2200MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords