STAINLESS STEEL PIPE CHEAP and GOOD QUALITY from CHINA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,the breif description of the cheap and good quality stainless steel pipe

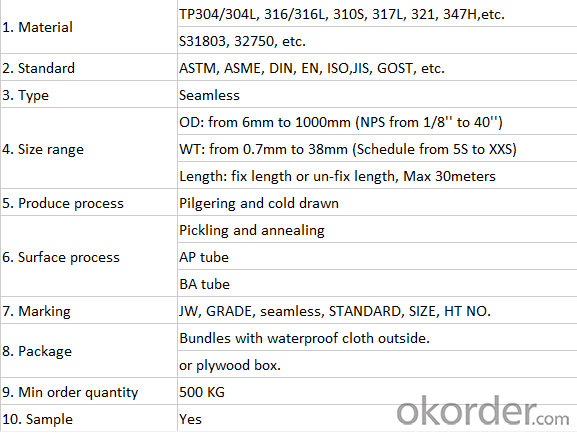

2,our advantage and specifications

1. Our company has been dedicated to producing stainless steel seamless pipe since 2003, owning complete producing technology and abundant managing experience.

2. The raw material such as mother tube, round bar we use is from Chinese biggest and well-known steel mill: Walsin Steel and Yongxing Steel.

3. We have advanced NDT equipments for the tests such as Eddy Current test, Ultrasonic test, Hydraulic test and so on.

4. We have ISO 9001 and PED certificate, and the Third Party Inspection Certificates such as TUV, BV, Lloyd’s, SGS, etc, also can be provided according to customers’ requirements,

5. Wooden case package which is strong and suitable for sea transportation is our main method to pack the pipes. And the economical packing method such as packed in bundles is also welcomed by some customers.

6. The tolerance control we use is D4/T4 (+/-0.1mm) on both inside and outside Diameter and Wall Thickness, which is much higher than international standard ASTM, DIN.

7. The surface condition is one of our main advantages: in order to meet different requirements for surface condition, we have annealing and pickling surface, bright annealing surface, OD polished surface, OD & ID polished surface etc.

8. In order to keep the inside surface of pipe clean and make it free from deburring, our company develops the unique and special technology --- Sponge Washing with high pressure.

9. We have complete after-sale service to deal with the problems in time.

3,Stainless steel maintenance:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

4,FAQ

1. Q: What are your advantageous Products?

A: We specialized in 400 series cold rolled stainless steel coils and plates. Our main products are 430, 410S and 409L.

We also supply stainless steel strips and strips in coil as requested.

2. Q: Can you make DDQ ( Deep Drawing Quality)?

A: Yes, we can. Our material can be used for stainless steel pots, stainless steel sinks, stainless steel bowls etc. U can tell us your usage, and we will adjust the mechanical propertise to meet your requirement.

- Q: What is the maximum pressure stainless steel pipes can handle?

- The maximum pressure that stainless steel pipes can handle varies depending on the grade and thickness of the stainless steel, as well as the specific application and conditions. However, stainless steel pipes are generally known for their high strength and durability, allowing them to withstand high pressures. It is advisable to consult with a professional engineer or refer to industry standards and guidelines to determine the specific maximum pressure rating for a given stainless steel pipe.

- Q: Can stainless steel pipes be used for brewery and beverage industry applications?

- Stainless steel pipes are suitable for use in brewery and beverage industry applications. This material is renowned for its exceptional corrosion resistance and hygienic properties, making it an ideal option for these sectors. The presence of high levels of chromium and nickel in stainless steel pipes provides excellent protection against corrosion caused by chemicals, acids, and high temperatures. Moreover, stainless steel pipes are easy to clean and maintain, ensuring the highest level of hygiene required in brewery and beverage production. The smooth inner surface of these pipes also reduces the risk of contamination and bacterial growth, making them even more suitable for these applications. In summary, stainless steel pipes offer durability, reliability, and sanitary features that make them the preferred choice for the brewery and beverage industry.

- Q: Can stainless steel pipes be magnetized?

- Yes, stainless steel pipes can be magnetized if they contain a sufficient amount of ferromagnetic elements, such as iron, nickel, or cobalt. However, most stainless steel pipes are non-magnetic due to the low iron content in their composition.

- Q: What is the difference between 304Cb and 316Cb stainless steel pipes?

- The main difference between 304Cb and 316Cb stainless steel pipes lies in their chemical composition and their respective properties. 304Cb stainless steel is an austenitic stainless steel alloy that contains chromium and nickel. It also has a small amount of niobium, which enhances its resistance to intergranular corrosion. This makes 304Cb stainless steel pipes suitable for a wide range of applications, including food processing, chemical and petrochemical industries, and architectural purposes. On the other hand, 316Cb stainless steel is also an austenitic stainless steel alloy that contains chromium and nickel. However, it has a higher percentage of molybdenum, which gives it superior resistance to corrosion and pitting in chloride environments. This makes 316Cb stainless steel pipes ideal for applications where exposure to saltwater or other corrosive substances is common, such as marine environments or coastal areas. In summary, while both 304Cb and 316Cb stainless steel pipes are excellent choices for various applications, 316Cb stainless steel offers better corrosion resistance in chloride environments due to its higher molybdenum content. Depending on the specific needs and environment of the application, one may be more suitable than the other.

- Q: Are stainless steel pipes suitable for power generation facilities?

- Stainless steel pipes are a perfect fit for power generation facilities due to their durability and resistance to corrosion. This material is highly reliable and can withstand extreme temperatures, pressure, and corrosive environments commonly found in power plants, including thermal, nuclear, and renewable energy generation plants. Moreover, stainless steel possesses exceptional heat resistance, making it an excellent choice for transporting hot gases or fluids in power generation systems. By resisting corrosion and maintaining their structural integrity over time, stainless steel pipes guarantee the dependability and longevity of power generation facilities.

- Q: What is the difference between stainless steel tube 304L and 304N?

- 304N is a nitrogen containing stainless steel and nitrogen is added to increase the strength of the steel.

- Q: What is the impact strength of stainless steel pipes?

- The impact strength of stainless steel pipes is generally high, making them resistant to cracking or breaking under applied force or impact. Stainless steel is known for its excellent toughness, which is the ability to absorb energy and deform without fracturing. This is due to its microstructure, which consists of a combination of austenite and ferrite phases. The presence of these phases provides stainless steel pipes with superior impact resistance compared to other materials. The impact strength of stainless steel pipes can vary depending on the specific grade or alloy used. For instance, austenitic stainless steels, such as grades 304 and 316, are known for their high impact strength. These grades are commonly used in various industries, including construction, oil and gas, and chemical processing, due to their ability to withstand impact loads without failure. Furthermore, stainless steel pipes can also be further enhanced through various heat treatment processes, such as tempering or quenching, to increase their impact strength. These processes modify the microstructure of the steel, resulting in improved mechanical properties, including higher toughness and impact resistance. Overall, stainless steel pipes have a strong impact strength, making them suitable for applications where resistance to impact or shock loading is required. Their ability to withstand high forces without fracturing or breaking ensures the durability and reliability of stainless steel pipes in various industries.

- Q: How do stainless steel pipes compare to PVC-U pipes?

- Various piping applications commonly utilize stainless steel pipes and PVC-U pipes, each possessing distinct characteristics and advantages. Primarily, stainless steel pipes are renowned for their remarkable strength and durability. With high resistance to corrosion, rust, and chemical reactions, they excel in applications where contact with aggressive substances or exposure to harsh environments is prevalent. Additionally, they can endure elevated temperatures and pressures, making them well-suited for demanding industrial uses. Conversely, PVC-U pipes, also known as polyvinyl chloride unplasticized pipes, offer lightweight properties and effortless installation. They provide cost-effective solutions and exhibit commendable chemical resistance, particularly against acids, alkalis, and salts. Plumbing, irrigation, and drainage systems commonly employ PVC-U pipes due to their superior flow characteristics and minimal maintenance requirements. Regarding versatility, stainless steel pipes cater to a broad spectrum of applications, including water supply, gas distribution, oil and gas pipelines, and sewage systems. They are frequently favored in industrial environments where reliability and longevity are paramount. Alternatively, PVC-U pipes find more widespread use in residential and commercial settings, prioritizing cost-efficiency and ease of installation. Notably, stainless steel pipes typically entail greater expense than PVC-U pipes, encompassing material costs and installation fees. Nonetheless, their extended lifespan and enhanced resistance to corrosion and chemical reactions often render them a more cost-effective option in the long term. Ultimately, the selection between stainless steel pipes and PVC-U pipes hinges on the specific requirements of the given application. Factors such as cost, durability, corrosion resistance, installation ease, and maintenance should all be contemplated when comparing these materials for a particular piping project.

- Q: Can stainless steel pipes be used in the petrochemical industry?

- Indeed, the petrochemical industry can utilize stainless steel pipes. Due to its exceptional resistance to corrosion and ability to endure elevated temperatures, stainless steel emerges as a perfect option for the transportation and storage of diverse petrochemical goods. Moreover, its durability and strength render it apt for managing the frequently encountered high-pressure circumstances within the petrochemical industry. Furthermore, stainless steel pipes facilitate effortless cleaning and maintenance, guaranteeing the purity and soundness of the petrochemical products during transportation. As a result, stainless steel pipes find widespread application in petrochemical plants, refineries, and other related facilities.

- Q: What is the difference between nominal size and actual size in stainless steel pipes?

- The distinction between nominal size and actual size in stainless steel pipes lies in their measurement and labeling methods. Nominal size refers to the assigned name of a pipe based on its approximate dimensions, typically in inches or millimeters. This name serves the purpose of easy identification and standardization. In contrast, actual size refers to the precise measurements of the pipe, including its outer diameter (OD) and wall thickness. These measurements are usually expressed in fractions of an inch or millimeters. The accurate dimensions are vital for determining the pipe's compatibility with fittings, valves, and other components, as well as for calculating flow rates and pressure ratings. It is important to acknowledge that the nominal size of a stainless steel pipe may not always align with its actual size. This discrepancy arises from historical factors and manufacturing practices. In certain instances, the nominal size may be slightly larger or smaller than the actual size to account for variations in wall thickness or to conform to industry standards. Therefore, when selecting stainless steel pipes, it is crucial to consider both the nominal size and the actual size to ensure proper fit and functionality. Referring to the manufacturer's specifications or seeking professional advice can aid in determining the appropriate pipe size for a specific application.

Send your message to us

STAINLESS STEEL PIPE CHEAP and GOOD QUALITY from CHINA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords