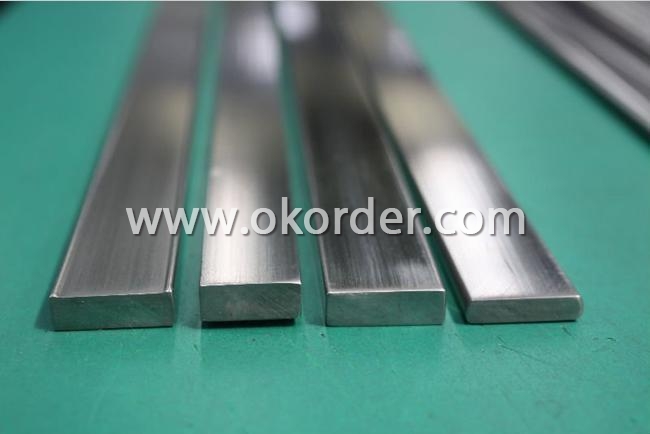

Stainless Steel Flats-XSTEEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats-XSTEEL

Details of Stainless Steel Flat Bar:

Thickness: 3mm - 15mm

Width: 25mm - 120mm

Inch Thickness: 1/8" - 5/8"mm

Width: 1" - 4.1/2"mm

Standard: ASTM A276/484M ,EN 10058/DIN 1017

Advantages of Stainless Steel Flat Bar :

1* All products are made of high quality material

2* More than 300 patterns

3* Favouable price&Considerable service

4* Fast delivery

5* Quickest and most efficient response to your inquiry

Specifications of Stainless Steel Flat Bar :

1. Prime stainless steel bar

2. Raw materials from TG

3. Independent factory

4. Deliverd within 3-7 days

5. Best service

- Q: Can stainless steel pipes be coated with PTFE?

- Yes, stainless steel pipes can be coated with PTFE (polytetrafluoroethylene) to improve their corrosion resistance, reduce friction, and provide a nonstick surface. The PTFE coating creates a protective barrier on the stainless steel, making it suitable for various applications in industries such as chemical processing, food processing, and pharmaceuticals.

- Q: Can stainless steel pipes be used in the agriculture industry?

- Yes, stainless steel pipes can be used in the agriculture industry. Stainless steel pipes are highly resistant to corrosion, making them ideal for agricultural applications where exposure to moisture, chemicals, and other corrosive substances is common. They are commonly used for irrigation systems, water supply lines, and various agricultural processes that require durable and long-lasting piping solutions. Additionally, stainless steel pipes are hygienic, easy to clean, and can withstand high temperatures, making them suitable for agricultural processes that involve food production and processing.

- Q: Can stainless steel pipes be painted?

- Indeed, it is possible to paint stainless steel pipes. Nevertheless, it should be taken into account that stainless steel is a non-porous substance with a sleek surface, posing difficulties for paint to adhere effectively. In order to achieve proper adhesion, it is advisable to diligently cleanse the surface and utilize a primer specially formulated for stainless steel. This will aid in creating a coarser texture on the surface, facilitating better bonding with the paint. Furthermore, opting for a superior, long-lasting paint suitable for metal surfaces will bolster the durability of the painted coating.

- Q: Can stainless steel pipes be used in the food and beverage industry?

- Yes, stainless steel pipes can be used in the food and beverage industry. Stainless steel is a popular choice for piping in this industry due to its excellent corrosion resistance, hygienic properties, and durability. Stainless steel pipes do not react with food or beverages, ensuring the integrity and safety of the products being transported. Additionally, stainless steel pipes are easy to clean and maintain, which is crucial for maintaining high levels of sanitation in food and beverage processing. Overall, stainless steel pipes are widely accepted and used in the food and beverage industry for their reliability and suitability for handling a wide range of products.

- Q: What wire is used for welding of 316 stainless steel line?

- Quality inspection of welding groove preparation, according to requirements of groove size, accuracy and surface quality stipulated in construction instruction and welding process instruction, groove quality including flatness, perpendicularity and cleanness.1, check the groove processing size (height, angle, edge and blunt edge, etc.) and accuracy isDoes it meet the relevant technical standards?.2, check the groove surface roughness and surface defects (cutting gap, crack,Layer and slag) if beyond the scope of the standard should be allowed to defect, repair treatment, such as surface roughness does not reach the standard, can use abrasive grinding.3. Check the surface cleaning quality of the groove. At least 200mm of the groove face and its sidesShould be clean within the scope, without burr, slag, rust, oil, film and paint and other harmful foreign bodies.4 、 nondestructive inspection of groove surface. For welding process documentation, specify the slopeMaterials such as CY-M steel, Fe-CY-N, high temperature steel and alloy steel shall be examined on the surface for nondestructive testing (such as coloring, etc.), and the defects such as cracks shall be removed.

- Q: Can stainless steel pipes be used for nuclear applications?

- Yes, stainless steel pipes can be used for nuclear applications. Stainless steel is commonly used in nuclear power plants due to its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It is particularly suitable for applications where the pipes come into contact with various nuclear substances or corrosive environments. Stainless steel pipes are used for transporting and containing nuclear materials, such as coolant, steam, and radioactive waste. They are also used in the construction of nuclear reactors, where the pipes need to withstand extreme conditions, including high pressure and radiation exposure. Additionally, stainless steel pipes offer long-term durability and reliability, making them a preferred choice for nuclear applications.

- Q: Why can stainless steel pipes be welded by argon arc welding?

- Argon protection can isolate the harmful effects of oxygen, nitrogen and hydrogen on the arc and molten pool in the air, and reduce the burning loss of alloy elements, so as to obtain compact, no spatter and high quality welded joints;

- Q: Are stainless steel pipes suitable for underground sewage systems?

- Yes, stainless steel pipes are suitable for underground sewage systems. They have excellent corrosion resistance, durability, and strength, which make them highly reliable for handling sewage and wastewater in underground applications.

- Q: Can stainless steel pipes be used for sewage disposal?

- Yes, stainless steel pipes can be used for sewage disposal. Stainless steel is highly resistant to corrosion, making it a suitable material for sewage pipes that are exposed to various chemicals and moisture. Additionally, stainless steel pipes have smooth surfaces, which helps prevent the buildup of debris and facilitates the flow of sewage.

- Q: Can stainless steel pipes be insulated with silicone?

- Indeed, it is possible to insulate stainless steel pipes using silicone. Silicone proves to be a highly adaptable substance capable of enduring a vast spectrum of temperatures, rendering it ideal for the purpose of insulating pipes that transport either hot or cold fluids. Typically, silicone insulation is obtainable in the form of sleeves or wraps, which can be effortlessly applied to the surface of the pipe. This insulation furnishes exceptional thermal insulation, thwarting any loss or gain of heat from the pipe and thereby enhancing energy efficiency. Furthermore, silicone insulation exhibits resistance towards moisture, chemicals, and UV radiation, guaranteeing its durability and long-standing efficacy.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 8 Million |

| Main Markets | China, East Asia, |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40% |

| No.of Employees in Trade Department | 30 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 26,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Flats-XSTEEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords