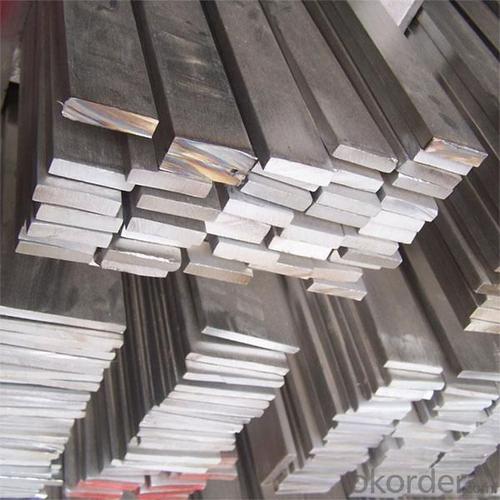

Stainless Steel Flats

- Loading Port:

- Shanghai Port or Others

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

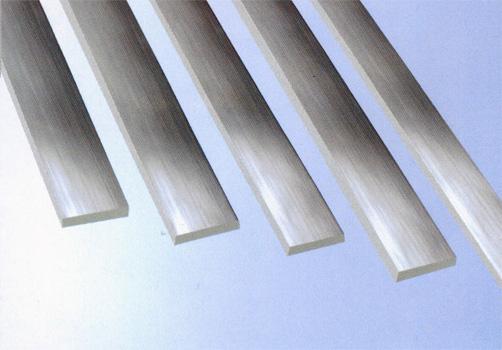

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

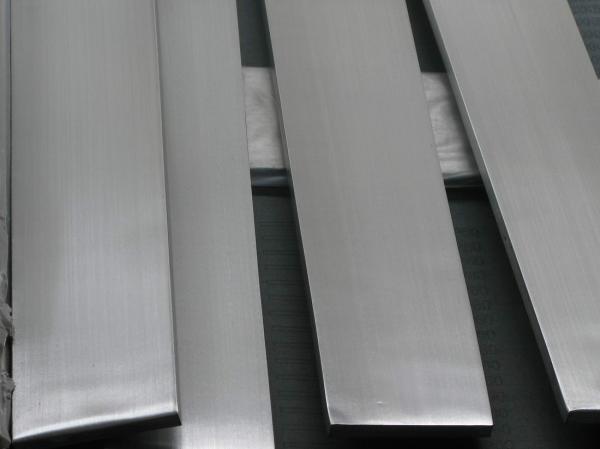

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. Cherryliu@okorder.com |

- Q: How do you test the quality of stainless steel pipes?

- There are multiple methods available to test the quality of stainless steel pipes. Let's explore these methods: 1. Visual Inspection: Start by visually examining the pipes for any visible defects such as cracks, dents, or surface irregularities. Carefully observe the pipes and check for any abnormalities. 2. Dimensional Inspection: Ensure that the dimensions of the stainless steel pipes meet the specified requirements. Measure the outer diameter, inner diameter, wall thickness, and length of the pipes using calibrated measuring instruments like calipers or micrometers. 3. Chemical Composition Analysis: To guarantee corrosion resistance and durability, stainless steel pipes must have a specific chemical composition. Conduct a chemical composition analysis using techniques like spectroscopy or wet chemical analysis to determine the presence and percentage of different elements in the steel. 4. Mechanical Properties Testing: The quality of stainless steel pipes can be assessed by evaluating mechanical properties such as tensile strength, yield strength, and elongation. Employ various testing methods like tensile testing, hardness testing, impact testing, or bending testing. These tests should adhere to relevant industry standards to ensure that the pipes meet the necessary mechanical specifications. 5. Non-destructive Testing: Detect hidden defects or inconsistencies within the stainless steel pipes without causing any damage using non-destructive testing methods like ultrasonic testing, X-ray inspection, or electromagnetic testing. These tests are beneficial in identifying flaws such as cracks, voids, or inclusions that may compromise the quality and performance of the pipes. 6. Corrosion Resistance Testing: Stainless steel pipes are well-known for their excellent corrosion resistance. Verify their resistance to corrosion by conducting tests such as salt spray testing or exposing them to harsh environments. These tests simulate real-life conditions and assess the pipes' ability to resist corrosion, ensuring their long-term durability. It is crucial to note that the specific testing methods and standards may vary depending on the industry or application requirements. Therefore, always refer to relevant standards and specifications when conducting quality tests on stainless steel pipes.

- Q: What are the different types of stainless steel pipe bends?

- There are several different types of stainless steel pipe bends available in the market. Some of the most commonly used types include: 1. Long radius bends: These bends have a larger radius compared to other types, which results in a smoother flow of fluid or gas through the pipe. They are often used in applications where the flow needs to be maintained at a consistent speed or where there are concerns about pressure drop. 2. Short radius bends: These bends have a smaller radius, which means they have a tighter curvature compared to long radius bends. They are typically used in applications where space is limited, such as in tight corners or in compact piping systems. 3. U-bends: U-bends have a 180-degree curve, forming a U-shape. They are commonly used in heat exchanger systems, where they allow for the efficient transfer of heat between two fluids. 4. 3D bends: 3D bends have a radius three times the diameter of the pipe. They are often used in applications where there is a need for a gradual change in direction, as they provide a smoother flow compared to sharper bends. 5. 5D bends: 5D bends have a radius five times the diameter of the pipe. They are typically used in applications where there are strict requirements for fluid or gas flow, as they minimize pressure drop and turbulence. 6. Mandrel bends: Mandrel bends are formed using a mandrel, which is a solid rod inserted into the pipe during the bending process. This helps maintain the shape and integrity of the pipe, resulting in a smooth and uniform bend. Mandrel bends are often used in applications where there are strict requirements for the roundness and smoothness of the bend. It is important to choose the right type of stainless steel pipe bend based on the specific requirements of the application, such as the fluid or gas being transported, the pressure and temperature conditions, as well as any space limitations. Consulting with a professional or supplier can help ensure the appropriate selection of pipe bends for the specific application.

- Q: What is the difference between 316 and 316Ti stainless steel pipes?

- The main difference between 316 and 316Ti stainless steel pipes lies in their carbon content. While both grades are highly corrosion-resistant and suitable for a wide range of applications, 316Ti contains a small amount of titanium, which gives it enhanced resistance to sensitization. Sensitization occurs when stainless steel is heated in the range of 500-900°C, causing the formation of chromium carbides that can lead to intergranular corrosion. By adding titanium, 316Ti stainless steel pipes are able to prevent the formation of these carbides by reacting with the carbon, thus maintaining the corrosion resistance of the material even when exposed to high temperatures. This makes 316Ti pipes more suitable for applications involving elevated temperatures or prolonged exposure to corrosive environments. In terms of mechanical properties, both grades exhibit similar strength and toughness. However, due to the addition of titanium, 316Ti may have slightly lower ductility compared to 316. It is important to note that the difference in carbon content between these two grades is small, typically less than 0.08%. In summary, the addition of titanium in 316Ti stainless steel pipes provides improved resistance to sensitization and intergranular corrosion, making it a preferred choice for applications involving high temperatures or corrosive environments.

- Q: Can stainless steel pipes be chromed?

- Indeed, it is possible to chrome stainless steel pipes. To achieve this, a layer of chromium is applied onto the surface of the stainless steel pipe through a process called chrome plating. Typically, this involves immersing the stainless steel pipe in a solution containing chromium salts, while an electric current is passed through the bath. As a result, the chromium adheres to the surface of the stainless steel pipe. This chrome plating not only enhances the appearance of the stainless steel pipe but also provides a protective finish, increasing its resistance to corrosion and wear.

- Q: About stainless steel welding deformation

- For welding of grade 304 stainless steel, the current can be adjusted a little, not preheating, to prevent deformation after welding, the welding sequence should pay attention to, such as left -- right -- in the welding line, avoid welding head, to prevent warping.

- Q: Are stainless steel pipes more expensive than other types of pipes?

- Generally speaking, stainless steel pipes tend to be pricier compared to other pipe variants. This can be attributed primarily to the expensive raw materials utilized in their production, along with the intricate manufacturing procedures involved. In addition, stainless steel pipes boast numerous advantages over alternative options, including exceptional resistance to corrosion, heightened durability, and the capacity to withstand extreme temperatures. These factors collectively contribute to their elevated price range. Nevertheless, for many applications, the long-term benefits and superior performance of stainless steel pipes often outweigh the additional cost, justifying their investment.

- Q: How much is one ton of stainless steel pipe?

- If you want to use industrial, production, 316L is the best, but the price is expensive, but the best rust resistance, high stability.

- Q: 304 stainless steel pipe, 20*2 pressure, how many kilograms?

- 304 stainless steel is a brand of stainless steel produced according to the ASTM standard in the United states. 304 is equivalent to 0Cr19Ni9 in our country(0Cr18Ni9) stainless steel. 304 chromium 19%, containing nickel 9%. The 304 is the most widely used stainless steel, heat-resistant steel, steel, steel industry utility. For food production equipment, general chemical equipment, nuclear energy, etc..

- Q: How do you calculate the flow rate of stainless steel pipes?

- To calculate the flow rate of stainless steel pipes, you can use the Hazen-Williams equation or the Darcy-Weisbach equation. The Hazen-Williams equation is commonly used for water flow in commercial and industrial applications, while the Darcy-Weisbach equation is more general and can be used for various fluids. For the Hazen-Williams equation, the flow rate (Q) can be calculated using the formula: Q = 0.849 * C * (D^2.63) * (h^0.54) Where: Q = Flow rate in gallons per minute (GPM) C = Hazen-Williams coefficient (an empirical value that depends on the pipe material and condition) D = Inside diameter of the pipe in inches h = Head loss or pressure drop in feet For the Darcy-Weisbach equation, the flow rate (Q) can be calculated using the formula: Q = (π/4) * (D^2) * V Where: Q = Flow rate in cubic meters per second (m³/s) D = Inside diameter of the pipe in meters V = Velocity of the fluid in meters per second (m/s) To determine the velocity (V), you can use the formula: V = Q / ((π/4) * (D^2)) These equations provide a theoretical estimation of the flow rate in stainless steel pipes. However, it is important to note that other factors such as pipe roughness, fluid viscosity, and system pressure can also affect the flow rate. Therefore, it is recommended to consult relevant engineering standards, industry guidelines, or work with a qualified engineer for accurate calculations.

- Q: How are stainless steel pipes different from carbon steel pipes?

- Stainless steel pipes are different from carbon steel pipes in terms of their composition and properties. Stainless steel pipes contain a higher percentage of chromium, which forms a protective layer on the surface, making them resistant to corrosion and rust. On the other hand, carbon steel pipes do not have this protective layer and are susceptible to corrosion. Stainless steel pipes are also more durable and have higher tensile strength compared to carbon steel pipes.

Send your message to us

Stainless Steel Flats

- Loading Port:

- Shanghai Port or Others

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords