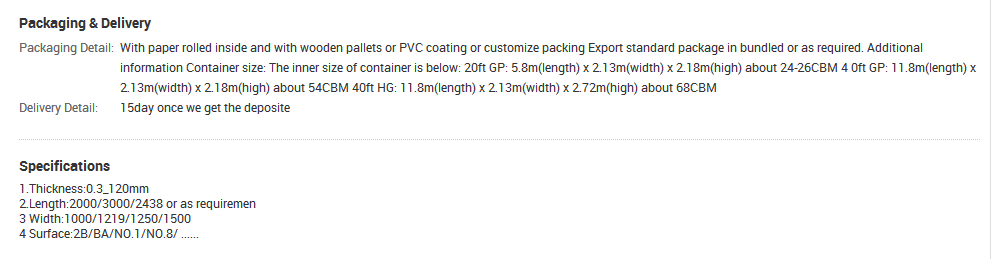

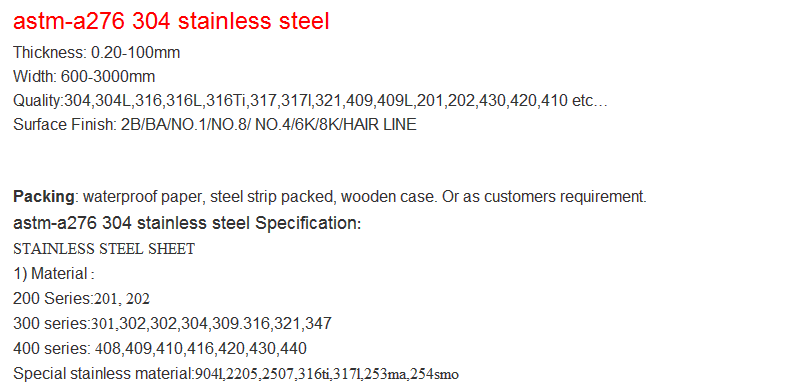

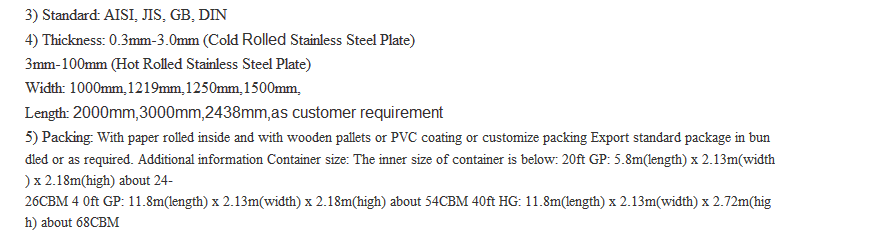

276 304 stainless steel,stainless steel sheet,stainless steel plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Can stainless steel pipes be used for sewage applications?

- Indeed, sewage applications can utilize stainless steel pipes. Stainless steel, being an extremely robust and corrosion-resistant material, proves to be an impeccable selection for managing sewage and wastewater. It exhibits resistance against chemicals and other harsh elements frequently encountered in sewage systems, guaranteeing enduring performance and minimal upkeep. Moreover, the smooth interior surfaces of stainless steel pipes diminish the chances of congestion or blockages caused by debris or accumulation. All in all, stainless steel pipes present themselves as a dependable and sanitary choice for sewage applications.

- Q: What is the difference between 316 and 316LN stainless steel pipes?

- 316 and 316LN stainless steel pipes are variations of the same stainless steel grade known as 316, but there are some distinctions between them. The primary disparity between 316 and 316LN stainless steel pipes resides in their nitrogen levels. 316LN stainless steel contains a higher nitrogen content than 316 stainless steel. The inclusion of nitrogen enhances the material's strength and corrosion resistance, making it more suitable for specific applications. Due to its elevated nitrogen content, 316LN stainless steel pipes display superior resistance to pitting and crevice corrosion, especially in chloride environments. This renders them particularly appropriate for utilization in marine settings or other scenarios where the pipes may encounter corrosive substances. Another contrast between the two grades lies in their availability and cost. 316 stainless steel pipes are more widely accessible and commonly employed, making them generally more cost-effective than 316LN stainless steel pipes. However, 316LN stainless steel pipes may be necessary for particular applications where enhanced corrosion resistance is required. In conclusion, the main difference between 316 and 316LN stainless steel pipes is their nitrogen content, which impacts their corrosion resistance properties. While 316 stainless steel is more readily available and cost-effective, 316LN stainless steel offers improved resistance to pitting and crevice corrosion, making it suitable for specific applications.

- Q: Can stainless steel pipes be used for structural purposes?

- Certainly, structural purposes can indeed employ stainless steel pipes. Stainless steel, renowned for its strength, durability, and resistance to corrosion, proves to be an exceptional substance for structural uses. Found commonly in industries like construction, architecture, and engineering, stainless steel pipes serve as structural support and facilitate the conveyance of fluids and gases. They possess the capability to endure heavy loads, extreme temperatures, and even harsh environmental circumstances, rendering them fitting for an extensive array of structural applications. Furthermore, stainless steel pipes offer customization options through various grades, sizes, and thicknesses, enabling them to cater to specific structural prerequisites.

- Q: Is stainless steel flexible enough for plumbing applications?

- Indeed, stainless steel proves itself to be sufficiently flexible for plumbing purposes. Renowned for their robustness and sturdiness, stainless steel pipes and fittings also possess a certain level of adaptability. This adaptability facilitates effortless installation in a wide range of plumbing systems, even those with intricate designs or confined spaces. Stainless steel pipes can be manipulated and molded without compromising their structural integrity, rendering them suitable for both residential and commercial plumbing ventures. Furthermore, stainless steel exhibits remarkable resistance to corrosion, a vital quality in plumbing scenarios where exposure to water and other corrosive substances is common. Overall, the combination of strength, durability, and flexibility that stainless steel offers makes it an excellent option for plumbing applications.

- Q: Can stainless steel pipes be used for sewage and wastewater systems?

- Yes, stainless steel pipes can be used for sewage and wastewater systems. Stainless steel is highly resistant to corrosion and rust, making it a durable and reliable choice for these applications. Additionally, stainless steel pipes can withstand high temperatures, pressure, and harsh chemicals, making them suitable for handling sewage and wastewater.

- Q: What is the difference between 2205 and 316L stainless steel pipes?

- The main difference between 2205 and 316L stainless steel pipes lies in their composition and properties. 2205 stainless steel is a duplex stainless steel, meaning it consists of a combination of austenite and ferrite phases. This composition provides excellent corrosion resistance and high strength. It is commonly used in applications that require resistance to stress corrosion cracking, such as marine environments and chemical processing plants. On the other hand, 316L stainless steel is an austenitic stainless steel known for its high corrosion resistance. It contains a higher percentage of chromium and nickel, which gives it superior resistance to pitting and crevice corrosion. It is commonly used in industries such as food processing, pharmaceuticals, and medical devices. In summary, while both 2205 and 316L stainless steel pipes offer corrosion resistance, 2205 provides higher strength and resistance to stress corrosion cracking, while 316L offers better resistance to pitting and crevice corrosion. The choice between the two will depend on the specific requirements of the application.

- Q: Can stainless steel pipes be wrapped with tape?

- Stainless steel pipes can indeed be wrapped with tape. However, it is crucial to use the appropriate tape specifically designed for stainless steel. The reason for this is that stainless steel pipes are commonly utilized in industrial and high-temperature settings, and regular tapes may not endure the extreme conditions. Typically, stainless steel pipe tapes are constructed from materials like stainless steel foil or aluminum foil, along with a heat-resistant adhesive, guaranteeing long-lasting durability and resistance to corrosion. These tapes serve a variety of purposes, including insulation, sealing, and protection against abrasion. It is always advisable to consult the manufacturer's guidelines or seek professional advice prior to applying any tape to stainless steel pipes, ensuring correct installation and avoiding any potential issues.

- Q: What is the difference between martensitic and precipitation-hardening stainless steel pipes?

- Martensitic and precipitation-hardening stainless steel pipes belong to two distinct categories of stainless steel alloys, each offering unique characteristics and properties. Renowned for their superior strength and hardness, martensitic stainless steel pipes are created through a process known as quenching and tempering. This involves rapidly cooling the material and then reheating it to attain the desired properties. This type of stainless steel is also magnetic and can undergo heat treatment to further bolster its strength. Martensitic stainless steel pipes are commonly utilized in applications requiring exceptional mechanical strength, such as automotive components and cutlery. In contrast, precipitation-hardening stainless steel pipes incorporate elements like copper, aluminum, or titanium into their composition. These additional elements enable the formation of precipitates during heat treatment, resulting in enhanced strength and corrosion resistance. Additionally, precipitation-hardening stainless steel pipes exhibit excellent weldability and can be easily machined. They find extensive application in industries such as aerospace, oil and gas, and chemical processing, where a combination of strength and corrosion resistance is of utmost importance. In summary, the primary distinction between martensitic and precipitation-hardening stainless steel pipes lies in their composition and the heat treatment procedures employed. Martensitic stainless steel pipes are hardened through quenching and tempering, delivering exceptional strength and hardness. Conversely, precipitation-hardening stainless steel pipes derive their strength from the formation of precipitates during heat treatment, providing a well-balanced combination of strength and corrosion resistance.

- Q: What's the difference between cold drawn steel tube and hot rolled steel tube?

- Cold drawn steel tube is a kind of precision cold drawn seamless pipe used for mechanical structure and hydraulic equipment with high dimensional accuracy and good surface finish. The use of precision seamless tube manufacturing machinery structure or hydraulic equipment, etc., can greatly save the working hours of mechanical processing, improve material utilization, at the same time help improve product quality.

- Q: Can stainless steel pipes be used for wastewater treatment?

- Yes, stainless steel pipes can be used for wastewater treatment. Stainless steel is a corrosion-resistant material that offers various benefits for wastewater treatment applications. It is highly durable and can withstand exposure to harsh chemicals and abrasive materials commonly found in wastewater. Stainless steel pipes are also resistant to rust, which ensures a longer lifespan and minimizes the risk of pipe failure. Additionally, stainless steel is inert and non-reactive, making it suitable for transporting and containing different types of wastewater without contamination. Its smooth surface prevents the buildup of deposits and biofilm, reducing the risk of clogging and allowing for efficient flow of wastewater. Overall, stainless steel pipes are a reliable and sustainable option for wastewater treatment systems.

Send your message to us

276 304 stainless steel,stainless steel sheet,stainless steel plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords