SUS 304 Stainless Steel Sheet & stainless steel plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specifications:

1) Surface: NO.1, 2B, BA, NO.3, NO.4, HL, NO.8 and so on.

2) Thickness: 0.3 to 80 mm

3) Width: 31 to 2000mm

4) Grade: 304, 304L, 316L, 321, 310S, 430, 409L, 201 etc.

Specification:

Type1 | Stainless steel coil |

Grade | 304,304L,316L,430,201,321,409L, etc. |

Thickness | 3.0-14mm(Hot rolled),0.3-6.0mm(cold rolled) |

Width | 1000/1219/1250/1500/1524/1800/2000mm or customized |

Diameter | 508mm,610mm |

Type2 | Stainless steel plate/sheet |

Grade | 304,304L,316L,430,201,321,409L, etc. |

Thickness | 3.0-80mm(Hot rolled),0.3-6.0mm(cold rolled) |

Width | 1000/1219/1250/1500/1524/1800/2000mm or customized |

Length | 500-6000 or customized |

Type 3 | Stainless steel strip |

Material | 304,304L,316L,430,201,321,409L, etc. |

Thickness | 3.0-8mm(Hot rolled),0.3-3.0mm(cold rolled) |

Width | 41-2000mm(Hot rolled),6-1550mm(cold rolled) |

Surface finish | NO.1, 2B, BA, NO.3, NO.4, HL, NO.8 and so on. |

Standard | ASTM,AISI, EN , DIN, JIS, GB, etc. |

Origin | BAOSTEEL,TISCO,TTSS,BAOXIN etc. |

Application range | Foodstuff, Gas, metallurgy, biology, electronic, chemical industry, petroleum, auto industry, beer tank. |

boiler, nuclear energy, Medical equipment, fertilizer etc. | |

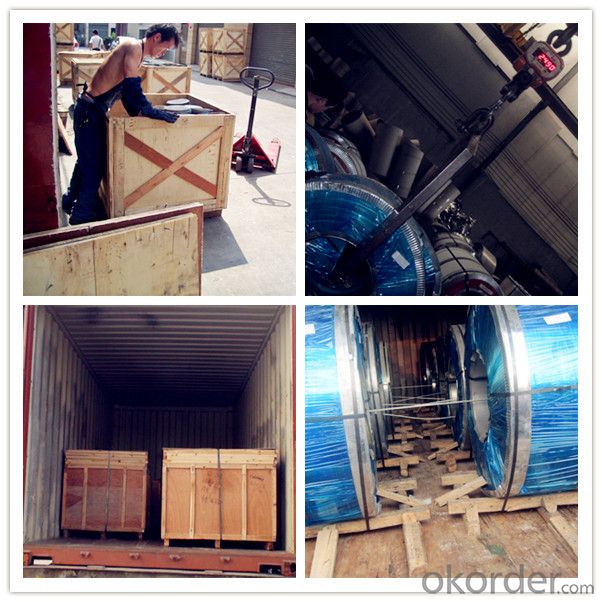

Packing | Standard export sea-worthy packing in wooden or squire pipe pallet. |

Delivery time | Normally 15-20 days(Stock),45-60 days (Production) |

Productivity | 5000-6000 tons/month |

Note | We can produce other standard as the customers’ requirement |

Trade details:

1. Mills origin: BAOSTEEL, TISCO, TTSS, BAOXIN, LISCO, ZPSS etc.

2. Delivery time: 10-20 days (Stock), 45-60days (production)

3. Payment: 30%- 100% T/T in advance, the rest balance against copy of B/L within 5 days or irrevocable LC at sight.

4.Shipment: Within 60 days or earlier as possible supplier can do to Shanghai port after the arrival of 30%TT deposit, or after the signature of contract if LC

5. Loading port: Shanghai/Ningbo, China.

6. Packing: As per export standard packing of Manufacturer, safety for transportation by container (suitable for container-carriage, protect against shock and discharging)

7. Inspection: Mills original material test report.

8. Quantity tol: +/-10% in total quantity and amount.

9. MOQ: 2ton per thickness.

More Products

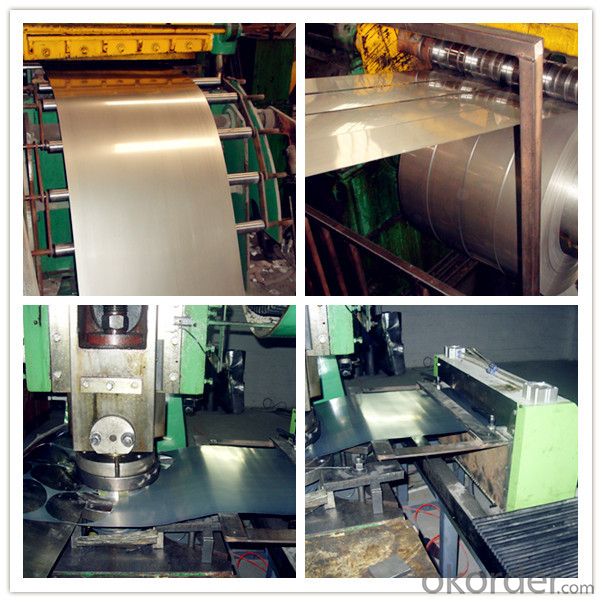

Manufacting

| Q&A corrugated steel sheet | |||||||

| 1 | Q: WHAT ARE YOUR MAIN PRODUCT? | ||||||

| A:We are specializing in providing cold rolled 201/410/430 Stainless Steel Coil / Stainless Steel Strip /Stainless Steel Sheet / Stainless Steel Plate, Stainless Steel Circle, Stainless Steel tube/ Stainless Steel Pipe Sheets. | |||||||

| 2 | Q: WHAT ARE YOUR ADVANTAGES? | ||||||

| 1. We have a strict quality control from production to delivery. 2. We use advanced system and tool to improve working efficiency and control every step. 3. We have a specialized team in dealing with all the documents required by customers. We aim to zero error to save money and time for client. | |||||||

| 3 | Q: CAN I GET FREE SAMPLE? | ||||||

| A: YES. We can provide free sample. But we are not responsible for the delivery fee . | |||||||

Packing & Loading

- Q:Stainless steel without fingerprint processing how to get?

- Stainless steel no fingerprint processing: the general situation is based on grinding, wire drawing, snow sand surface processing, oil processing process done, the oil is oil - high temperature high temperature cleaning - drying - film, so the milling surface of stainless steel plate with a layer of transparent film, with a finger to touch no generate fingerprints clearly, so called "no fingerprint stainless steel".

- Q:Can stainless steel sheets be used for hygienic environments?

- Yes, stainless steel sheets can be used for hygienic environments. Stainless steel is a popular choice for such environments due to its inherent properties that make it highly resistant to corrosion, heat, and chemical damage. Its smooth and non-porous surface is easy to clean, preventing the accumulation of bacteria, mold, or other contaminants. Stainless steel is also non-reactive and does not release any harmful substances, making it suitable for sensitive environments such as food processing facilities, hospitals, pharmaceutical labs, and cleanrooms. Additionally, stainless steel is durable and long-lasting, providing excellent hygiene and cleanliness for extended periods. Overall, stainless steel sheets are a reliable and hygienic choice for various applications in environments that prioritize cleanliness and sanitation.

- Q:Can stainless steel sheets be used for outdoor furniture or fixtures?

- Yes, stainless steel sheets can be used for outdoor furniture or fixtures. Stainless steel is highly resistant to corrosion, making it a suitable material for outdoor applications. It is durable, weather-resistant, and can withstand harsh environmental conditions. Additionally, stainless steel has an attractive appearance and can be easily cleaned and maintained, making it an ideal choice for outdoor furniture or fixtures.

- Q:How do you prevent intergranular corrosion on stainless steel sheets?

- Intergranular corrosion is a type of corrosion that occurs along the grain boundaries of stainless steel, leading to structural damage and reduced strength. To prevent intergranular corrosion on stainless steel sheets, several measures can be taken: 1. Material Selection: Choosing the right grade of stainless steel is crucial in preventing intergranular corrosion. Grades with low carbon content, such as 304L or 316L, are less prone to this type of corrosion due to their reduced susceptibility to sensitization. 2. Heat Treatment: Stainless steel sheets can be heat treated to remove carbide precipitation, a common cause of intergranular corrosion. The process, known as solution annealing or sensitization heat treatment, involves heating the material to a specific temperature range and then rapidly cooling it. This treatment ensures the formation of a consistent and corrosion-resistant microstructure. 3. Passivation: Passivation is a chemical process that removes contaminants and forms a protective oxide layer on the surface of stainless steel sheets. This layer acts as a barrier against corrosion and prevents intergranular attack. Passivation is typically done using nitric acid or citric acid solutions. 4. Welding Techniques: When welding stainless steel sheets, it is important to use proper welding techniques to minimize the risk of intergranular corrosion. This includes using low heat input, avoiding excessive heat build-up, and employing filler materials with low carbon content to prevent sensitization. 5. Avoiding Contamination: Stainless steel sheets should be protected from contamination by other metals, especially those with higher galvanic potentials. Contact with carbon steel, for example, can result in galvanic corrosion and promote intergranular attack. Therefore, it is essential to separate stainless steel sheets from other metals in storage and during fabrication. 6. Regular Cleaning and Maintenance: Regular cleaning and maintenance of stainless steel sheets are essential to prevent the accumulation of corrosive substances or contaminants on the surface. Proper cleaning methods and non-abrasive cleaners should be used to avoid scratching the stainless steel, which can create sites for corrosion initiation. By implementing these preventive measures, intergranular corrosion can be significantly minimized, ensuring the longevity and performance of stainless steel sheets.

- Q:Can stainless steel sheets be used for medical equipment?

- Yes, stainless steel sheets can be used for medical equipment. Stainless steel is widely used in the medical industry due to its excellent corrosion resistance, durability, and ease of cleaning. It is commonly used for surgical instruments, implants, medical devices, and equipment such as sterilization trays, hospital beds, and operating room tables. Stainless steel is non-reactive, which means it does not interact with body tissues or fluids, making it a safe and hygienic choice for medical applications. Additionally, stainless steel can withstand repeated sterilization processes without losing its properties, making it ideal for use in hospitals and healthcare facilities.

- Q:Can stainless steel sheets be used for elevator mirror panels?

- Yes, stainless steel sheets can be used for elevator mirror panels. Stainless steel is a durable and corrosion-resistant material that is commonly used in elevator design and construction. It is also highly reflective, making it an ideal choice for mirror panels. Stainless steel mirror panels not only provide a sleek and modern aesthetic to elevators but also offer excellent durability and ease of maintenance. Additionally, stainless steel can withstand the wear and tear of constant use, making it a reliable and long-lasting material for elevator mirror panels.

- Q:Can stainless steel sheets be used for kitchen countertops?

- Yes, stainless steel sheets can be used for kitchen countertops. Stainless steel is a durable and hygienic material that is resistant to stains, heat, and bacteria. It is a popular choice for kitchen countertops due to its modern aesthetic, easy maintenance, and ability to withstand heavy use.

- Q:What are the different types of stainless steel sheet surface coatings for outdoor applications?

- There are several types of stainless steel sheet surface coatings commonly used for outdoor applications, including brushed, mirror, satin, and textured finishes. These coatings vary in terms of their appearance and performance characteristics, offering options for different aesthetic preferences and levels of durability and resistance to corrosion.

- Q:Can stainless steel sheets be used for architectural cladding?

- Yes, stainless steel sheets can be used for architectural cladding. Stainless steel is a versatile material that offers a range of benefits for architectural applications. It is highly resistant to corrosion, making it suitable for both interior and exterior cladding in various environments. Stainless steel sheets are also durable and require minimal maintenance, which is advantageous for long-term use in architectural projects. Additionally, stainless steel has an attractive appearance and can be finished in different ways, allowing architects to achieve the desired aesthetic for their designs. Its strength and fire resistance properties further enhance its suitability for architectural cladding. Overall, stainless steel sheets are a popular choice for architectural cladding due to their durability, corrosion resistance, aesthetic appeal, and versatility.

- Q:How do you restore the shine or finish on stainless steel sheets?

- To restore the shine or finish on stainless steel sheets, there are a few methods you can try: 1. Cleaning with warm water and soap: Start by cleaning the stainless steel sheets with warm water and a mild dish soap. Use a soft cloth or sponge to gently scrub the surface, then rinse with clean water and dry thoroughly with a clean cloth. This should remove any dirt or grime that is dulling the shine. 2. Vinegar solution: If the stainless steel sheets have stubborn stains or dull spots, you can try using a vinegar solution. Mix equal parts white vinegar and water in a spray bottle, then spray the solution onto the surface. Let it sit for a few minutes, then wipe it off with a soft cloth. Vinegar helps to remove stains and restore shine to stainless steel. 3. Baking soda paste: For tougher stains or scratches on stainless steel sheets, you can create a paste using baking soda and water. Mix enough baking soda with water to form a thick paste, then apply it to the stained areas. Gently scrub the surface with a soft cloth or sponge, moving in the direction of the grain. Rinse with water and dry thoroughly. 4. Stainless steel cleaner: There are commercial stainless steel cleaners available that are specifically designed to restore the shine and finish of stainless steel. Follow the instructions on the cleaner and apply it to the surface using a soft cloth or sponge. Rub gently in the direction of the grain and rinse with water. Dry thoroughly to avoid water spots. Remember, always test any cleaning method or solution on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. This will help ensure that the method or solution does not cause any damage or discoloration.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SUS 304 Stainless Steel Sheet & stainless steel plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords