304/316 stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel pipe

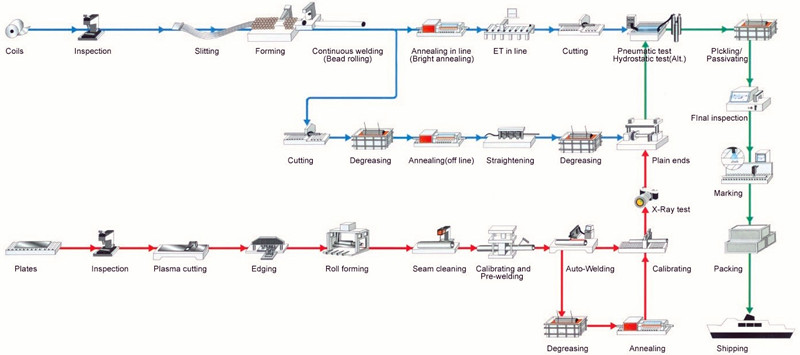

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:21.3*3.73mm or others

2.Surface:4k/6k//8k

3.Length:6m or as your requirement

A series of photos

A series of pictures

- Q: Are stainless steel pipes suitable for air conditioning systems?

- Yes, stainless steel pipes are suitable for air conditioning systems. They offer excellent corrosion resistance, durability, and can withstand high temperatures and pressure levels commonly found in air conditioning systems. Stainless steel pipes also ensure clean air quality and are easy to maintain, making them a reliable choice for air conditioning installations.

- Q: What is the significance of the schedule in stainless steel pipes?

- The schedule in stainless steel pipes refers to the thickness of the pipe walls. It plays a significant role in determining the strength, durability, and pressure handling capabilities of the pipe. The schedule is denoted by a numerical value, such as Schedule 10, Schedule 40, or Schedule 80, which represents the thickness of the pipe. The significance of the schedule lies in its impact on the pipe's ability to withstand various applications and conditions. A higher schedule number indicates a thicker wall, which translates to increased strength and resistance to internal and external pressures. This makes stainless steel pipes with a higher schedule suitable for high-pressure and high-temperature applications, such as industrial processes, oil and gas pipelines, and chemical processing plants. Moreover, the schedule also affects the flow capacity of the pipe. Thicker-walled pipes have a smaller internal diameter, reducing the flow rate compared to pipes with thinner walls. This factor is crucial when considering the fluid flow requirements in plumbing systems, HVAC installations, and other applications. The choice of the appropriate schedule for stainless steel pipes depends on the specific requirements of the project, including the pressure, temperature, and flow conditions. It is essential to select the correct schedule to ensure the pipe can handle the intended application safely and efficiently. In summary, the significance of the schedule in stainless steel pipes lies in its influence on the strength, pressure handling capabilities, and flow capacity. By understanding the schedule, engineers and professionals can make informed decisions when selecting and installing stainless steel pipes for various industrial, commercial, and residential applications.

- Q: Can stainless steel pipes be hardened?

- Indeed, the hardening of stainless steel pipes can be achieved by means of a technique known as cold working. To elaborate, this procedure entails subjecting the stainless steel pipes to deformation when exposed to low temperatures, accomplished through methods such as rolling, drawing, or bending. By undertaking this process, the material's strength and hardness are enhanced, all the while preserving its resistance to corrosion. Nevertheless, it is crucial to acknowledge that stainless steel pipes cannot be hardened via heat treatment akin to carbon steels, given that their composition already imparts them with a formidable degree of hardness.

- Q: What is the difference between annealed and tempered stainless steel pipes?

- Both annealed and tempered stainless steel pipes undergo heat treatment to improve their properties, but they differ in terms of mechanical characteristics and applications. Annealed stainless steel pipes are made soft and ductile through the annealing process. This process involves heating the material to a high temperature and then slowly cooling it, relieving internal stresses and increasing flexibility. As a result, these pipes are easier to bend and shape. While annealed pipes have lower hardness and strength, they are more resistant to corrosion. On the other hand, tempered stainless steel pipes go through a different heat treatment called tempering. After quenching, the steel is reheated to a specific temperature and then rapidly cooled. This process enhances the steel's strength, hardness, and toughness, making it suitable for applications requiring high mechanical properties. Tempered pipes have greater hardness and strength, but their corrosion resistance may be slightly lower compared to annealed pipes. The choice between annealed and tempered stainless steel pipes depends on the specific application. Annealed pipes are commonly used in industries that prioritize excellent corrosion resistance and flexibility, such as the food processing, pharmaceutical, and chemical sectors. Conversely, tempered pipes are preferred in applications requiring greater strength and durability, like construction, automotive, and aerospace industries. In summary, annealed stainless steel pipes are softer and more flexible, offering better corrosion resistance. On the other hand, tempered stainless steel pipes are stronger and harder, with slightly reduced corrosion resistance. The appropriate type selection depends on the mechanical requirements and the environment in which the pipes will be used.

- Q: What are the different surface finishes available for stainless steel pipes?

- There are several different surface finishes available for stainless steel pipes, each with its own unique characteristics and uses. 1. Mill Finish: This is the basic finish that stainless steel pipes come with after manufacturing. It has a dull, rough appearance and is suitable for applications where aesthetics are not a major concern. 2. Brushed Finish: Also known as satin finish, this surface finish is achieved by brushing the stainless steel pipe with abrasive material. It creates a smooth, brushed appearance with fine lines running in one direction. Brushed finish is commonly used in architectural applications and can provide a more polished look compared to the mill finish. 3. Mirror Finish: This is the most reflective surface finish available for stainless steel pipes. It is achieved by polishing the surface to a high gloss using progressively finer abrasives. Mirror finish is commonly used in decorative applications and provides a sleek, reflective appearance. 4. Polished Finish: This finish falls between the brushed and mirror finishes. It is achieved by polishing the surface to a smooth, shiny appearance using finer abrasives than the brushed finish. Polished finish is often used in applications where a more refined, but not overly reflective, look is desired. 5. Bead Blasted Finish: This finish is achieved by blasting small glass beads against the surface of the stainless steel pipe, creating a uniform matte appearance. Bead blasted finish is commonly used in industrial applications where a non-reflective surface is required, such as in food processing or pharmaceutical industries. 6. Electropolished Finish: This is a specialized surface finish that involves electrochemical polishing of the stainless steel pipe. It removes surface imperfections, enhances corrosion resistance, and creates a smooth, bright appearance. Electropolished finish is commonly used in industries that require high sanitary standards, such as pharmaceutical and biotechnology. These are just a few of the different surface finishes available for stainless steel pipes. The choice of finish depends on the specific application requirements, such as aesthetics, corrosion resistance, and cleanliness.

- Q: What are the common sizes of stainless steel pipes used in construction?

- The specific application and requirements determine the varying common sizes of stainless steel pipes used in construction. However, numerous construction projects commonly utilize a few standard sizes. These sizes encompass 1/2 inch, 3/4 inch, 1 inch, 1.5 inches, 2 inches, 3 inches, 4 inches, 6 inches, and 8 inches. Distinct purposes are associated with these sizes. For plumbing and water supply systems in residential and commercial buildings, smaller sizes like 1/2 inch, 3/4 inch, and 1 inch are frequently employed. They are also applicable for gas lines and ventilation systems. Larger sizes like 1.5 inches, 2 inches, 3 inches, and 4 inches are predominantly utilized in industrial contexts, including oil and gas pipelines, chemical processing plants, and power generation facilities. These pipes are engineered to accommodate higher flow rates and pressure demands. Moreover, even larger sizes like 6 inches and 8 inches find utility in specialized applications, such as large-scale industrial projects and infrastructure development. Water treatment plants, wastewater treatment facilities, and large-scale irrigation systems often employ these sizes. It is vital to acknowledge that these common sizes represent only a portion of the available options, as numerous other sizes are contingent upon the specific requirements of a construction project. Consultation with a professional engineer or contractor is always advisable to determine the appropriate size of stainless steel pipes for a particular construction endeavor.

- Q: What is the difference between seamless and hot-expanded stainless steel pipes?

- Seamless and hot-expanded stainless steel pipes are two different types of manufacturing processes for producing stainless steel pipes. Seamless stainless steel pipes are made by piercing a solid billet of stainless steel and then rolling it into a pipe shape. This process does not involve any welding or joining of separate pieces, resulting in a seamless pipe. Seamless pipes are known for their uniformity and strength, as there are no weak points or potential leak paths in the pipe. They are generally more expensive to produce and are used in applications where high corrosion resistance and pressure handling are required, such as in the oil and gas industry or in high-pressure boilers. On the other hand, hot-expanded stainless steel pipes are made by heating a stainless steel pipe and expanding it to a larger diameter using a mandrel inside the pipe. This process creates a larger diameter pipe with a uniform wall thickness. Hot expansion is typically used to produce larger diameter pipes that are required for specific applications. The hot expansion process can improve the mechanical properties of the pipe, such as increased tensile strength and improved resistance to corrosion. These pipes are commonly used in industries such as petrochemical, power generation, and construction. In summary, the main difference between seamless and hot-expanded stainless steel pipes lies in their manufacturing processes and the resulting properties of the pipes. Seamless pipes are made by rolling a solid billet, while hot-expanded pipes are created by heating and expanding an existing pipe. Seamless pipes are known for their strength and uniformity, while hot-expanded pipes are often used for larger diameter applications and can have improved mechanical properties.

- Q: What is the difference between 304LN and 316LN stainless steel pipes?

- The main difference between 304LN and 316LN stainless steel pipes lies in their chemical composition and corrosion resistance properties. 304LN stainless steel pipes contain a higher percentage of chromium and nickel, making them more resistant to corrosion in general applications. On the other hand, 316LN stainless steel pipes have a higher content of molybdenum, which enhances their resistance to pitting and crevice corrosion, especially in chloride environments. Therefore, 316LN stainless steel pipes are often preferred in more corrosive and aggressive environments, such as marine or coastal applications, while 304LN stainless steel pipes are suitable for regular industrial and commercial use.

- Q: How do stainless steel pipes compare to fiberglass pipes?

- Distinct characteristics and advantages set stainless steel pipes and fiberglass pipes apart. When comparing the two, one must consider factors such as strength, durability, corrosion resistance, cost, and ease of installation. In terms of strength, stainless steel pipes have a clear advantage, known for their exceptional strength and durability. They can withstand high-pressure applications and heavy loads. On the other hand, fiberglass pipes are relatively weaker and may not be suitable for high-strength and resistance applications. Durability is another crucial aspect. Stainless steel pipes are highly durable, enduring extreme temperatures, chemicals, and physical stress without deteriorating. Fiberglass pipes, though durable, are more susceptible to damage from impact, extreme temperatures, and UV radiation. Therefore, stainless steel pipes are a more reliable choice for long-term use in harsh environments. Corrosion resistance is significant when selecting pipes. Stainless steel pipes are renowned for their excellent corrosion resistance, making them ideal for applications where exposure to corrosive substances is a concern. Fiberglass pipes, while relatively resistant to many chemicals, can be affected by certain corrosive substances and may require additional protective coatings. Cost is an important consideration for any project. Due to the higher cost of raw materials and manufacturing processes, stainless steel pipes tend to be more expensive than fiberglass pipes. Conversely, fiberglass pipes are generally more affordable, making them a cost-effective option for budget-constrained projects. Finally, ease of installation is worth mentioning. The weight and rigidity of stainless steel pipes require specialized tools and expertise for installation. In contrast, fiberglass pipes being lightweight and flexible, are easier to handle and install, reducing labor costs and time. In conclusion, stainless steel pipes offer superior strength, durability, and corrosion resistance compared to fiberglass pipes. However, fiberglass pipes are a more cost-effective option and easier to install. Ultimately, the choice between the two depends on the specific project requirements, considering factors such as application, budget, and environmental conditions.

- Q: Can stainless steel pipes be insulated with cellulose?

- Yes, stainless steel pipes can be insulated with cellulose. Cellulose insulation is a common choice for insulating pipes due to its high thermal resistance and fire-resistant properties. It can be used on various types of pipes, including stainless steel. Cellulose insulation can be applied to the pipes using different methods, such as wrapping the pipes with cellulose insulation blankets or filling the pipe cavities with loose-fill cellulose insulation. Insulating stainless steel pipes with cellulose can help prevent heat loss, reduce energy consumption, and ensure the pipes maintain a consistent temperature.

Send your message to us

304/316 stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords