Stainless Steel Bright Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 2500MT Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

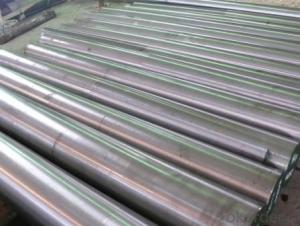

Stainless Steel Bright Bar

Thickness: 3mm - 40mm

Width: 20mm - 120mm

Standard: ASTM A276/484M ,EN 10278/DIN 174

- Q: Can stainless steel pipes be used for air conditioning systems?

- Indeed, air conditioning systems can utilize stainless steel pipes. Given its durability and resistance to corrosion, stainless steel proves to be a fitting material for a wide range of applications, including air conditioning systems. With their exceptional resistance to oxidation and rust, stainless steel pipes guarantee prolonged use and ward off any potential leakage. Moreover, these pipes possess the capacity to withstand elevated temperatures and pressure, rendering them perfect for integration within air conditioning systems.

- Q: Can stainless steel pipes be used for underground sewage systems?

- Certainly! Underground sewage systems can indeed utilize stainless steel pipes. Due to its exceptional durability and resistance to corrosion, stainless steel is an ideal material for underground applications that frequently encounter moisture and chemicals. It can effectively endure the demanding conditions of sewage systems, including the erosive properties of wastewater and the pressure exerted by the soil. Moreover, stainless steel pipes boast an extensive lifespan, minimizing the necessity for frequent replacements and upkeep. Nevertheless, it is crucial to carefully assess the unique prerequisites and regulations of the local sewage system, and seek advice from experts to guarantee appropriate installation and compatibility with other system components.

- Q: What are the common sizes and dimensions of stainless steel pipes?

- There are various common sizes and dimensions of stainless steel pipes available, ranging from small diameters of 1/8 inch to large diameters of 36 inches or more. The wall thicknesses can vary depending on the application, but commonly range from Schedule 5S (thin) to Schedule 160 (thick). The lengths of stainless steel pipes are typically standardized at 20 feet.

- Q: Are stainless steel pipes suitable for water desalination plants?

- Yes, stainless steel pipes are suitable for water desalination plants. Stainless steel is an excellent material choice for water desalination plants due to its corrosion resistance, durability, and hygienic properties. These pipes are highly resistant to rust, corrosion, and scaling, ensuring a long lifespan and minimal maintenance requirements. Additionally, stainless steel pipes do not leach harmful substances into the water, making them safe for use in desalination plants. Their high strength and pressure-bearing capacity also make them ideal for handling the high-pressure environments commonly found in water desalination processes. Overall, stainless steel pipes provide reliable and efficient water transport in desalination plants, contributing to the production of clean and safe drinking water.

- Q: Are stainless steel pipes suitable for oil and gas applications?

- Indeed, oil and gas applications find stainless steel pipes to be appropriate. Stainless steel boasts exceptional corrosion resistance, rendering it the perfect choice for the conveyance and storage of oil and gas, substances that frequently harbor corrosive components. Additionally, stainless steel pipes exhibit remarkable strength and durability, guaranteeing their ability to endure high-pressure circumstances and unforgiving surroundings. Moreover, stainless steel proves effortless to cleanse and uphold, thus diminishing the likelihood of contamination within oil and gas operations. All in all, stainless steel pipes emerge as a dependable and economically viable option for oil and gas applications.

- Q: Can stainless steel pipes be inspected for defects?

- Yes, stainless steel pipes can be inspected for defects. There are various methods and techniques available for inspecting stainless steel pipes to identify any defects or flaws. One commonly used method is visual inspection, where trained inspectors visually examine the external surface of the pipes to detect any visible defects such as cracks, corrosion, or dents. In addition to visual inspection, non-destructive testing (NDT) methods can also be employed to inspect stainless steel pipes. NDT techniques such as ultrasonic testing, radiographic testing, magnetic particle testing, and dye penetrant testing can be used to identify internal defects like cracks, weld flaws, or any other discontinuities that may compromise the integrity of the pipe. These inspection methods help ensure that stainless steel pipes meet the required quality standards and specifications. By identifying defects early on, appropriate measures can be taken to rectify or replace the flawed pipes, thus ensuring safe and reliable performance in various applications such as plumbing, oil and gas pipelines, and industrial processes.

- Q: What is the difference between seamless and hot-expanded stainless steel pipes?

- Two distinct methods exist for manufacturing stainless steel pipes: seamless and hot expansion. Seamless stainless steel pipes are formed by piercing a solid billet of stainless steel and rolling it into the desired pipe shape. In this process, there is no welding or joining of separate pieces, resulting in a seamless pipe. These pipes are renowned for their uniformity and strength, as they lack weak points or potential leak paths. Although more expensive to produce, they are essential in applications requiring high corrosion resistance and pressure handling, such as in the oil and gas industry or high-pressure boilers. Conversely, hot-expanded stainless steel pipes are created by heating a stainless steel pipe and expanding it to a larger diameter using a mandrel within the pipe. This method is employed to produce larger diameter pipes for specific purposes. The hot expansion process can enhance the mechanical properties of the pipe, including increased tensile strength and improved corrosion resistance. Industries such as petrochemical, power generation, and construction frequently employ these pipes. In conclusion, the key distinction between seamless and hot-expanded stainless steel pipes lies in their manufacturing processes and resulting properties. Seamless pipes are crafted by rolling a solid billet, while hot-expanded pipes are formed by heating and expanding an existing pipe. Seamless pipes are recognized for their strength and uniformity, while hot-expanded pipes are often utilized for larger diameter applications and can possess enhanced mechanical properties.

- Q: What is the difference between ERW and EFW stainless steel pipes?

- ERW (Electric Resistance Welded) and EFW (Electric Fusion Welded) are two different methods used for manufacturing stainless steel pipes. The main difference between the two lies in the welding process. ERW stainless steel pipes are manufactured by rolling a flat sheet of steel into a cylindrical shape and then welding the edges together using a high-frequency electrical current. This process creates a strong, seamless joint between the two edges of the sheet, resulting in a pipe that is highly resistant to corrosion and has a smooth interior surface. ERW pipes are commonly used in applications where strength and durability are required, such as in the oil and gas industry. On the other hand, EFW stainless steel pipes are made by applying a combination of heat and pressure to melt the edges of two pieces of steel and then welding them together. This fusion welding process results in a pipe that has a continuous weld along its entire length, eliminating the need for any additional welding. EFW pipes are known for their excellent corrosion resistance and are often used in applications where high-pressure and high-temperature conditions are present, such as in chemical plants and power generation facilities. In summary, the main difference between ERW and EFW stainless steel pipes lies in the welding process. ERW pipes are made by welding the edges of a flat sheet, while EFW pipes are made by fusing the edges of two pieces of steel. Both methods have their respective advantages and are used in different applications depending on the specific requirements of the project.

- Q: How do stainless steel pipes compare to other materials like carbon steel or PVC?

- Stainless steel pipes have several advantages over other materials such as carbon steel or PVC. Firstly, they are highly resistant to corrosion, making them suitable for use in various environments, including those with high humidity or exposure to chemicals. Additionally, stainless steel pipes have excellent strength and durability, allowing them to withstand high pressures and temperatures. They also have a smooth internal surface, which reduces friction and minimizes the risk of clogs or blockages. While carbon steel pipes may be less expensive, stainless steel pipes offer superior longevity and performance. PVC pipes, on the other hand, are lightweight and cost-effective but may not be as durable or resistant to extreme conditions as stainless steel. Overall, stainless steel pipes are a reliable and versatile choice for many applications.

- Q: Are stainless steel pipes suitable for food processing applications?

- Stainless steel pipes prove to be highly suitable for food processing applications, primarily due to their unique properties that render them hygienic, resistant to corrosion, and easily cleanable. The smooth surface of these pipes effectively prevents the accumulation of bacteria and other contaminants, thus ensuring the safety and purity of food products. Moreover, stainless steel exhibits non-reactivity, making it incapable of imparting taste, odor, or color to the processed food. Consequently, it emerges as an ideal choice for various industries, including dairy, brewing, and food processing, where the preservation of product integrity stands paramount. Additionally, stainless steel pipes boast exceptional strength and durability, enabling them to withstand the demanding requirements of food processing operations. In conclusion, stainless steel pipes possess the necessary attributes to uphold the highest standards of food safety and quality.

Send your message to us

Stainless Steel Bright Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 2500MT Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords