ASTM A106/53 Stainless Steel Welded Tube manufacturer for oil Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 kg

- Supply Capability:

- 12000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless Pipe ASTM A106/53:

carbon seamless steel pipes are widely used in gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

2、Main Features of the Seamless Pipe ASTM A106/53:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

● Professional teams ensure a high efficiency of your purchase

▲ Professional sales team

▲ Professional engineering and technology team

▲ Professional exportation and contract processing/management team

▲ Professional cooperators and partners

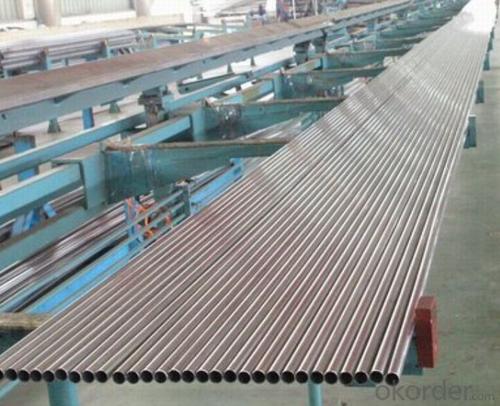

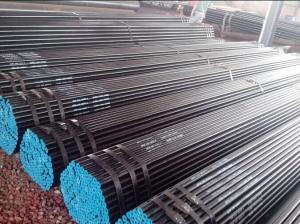

6、Seamless Pipe ASTM A106/53 Images:

- Q: What is the difference between bright annealed and annealed pickled stainless steel pipes?

- There are two distinct surface finishes for stainless steel pipes: bright annealed and annealed pickled. Bright annealed pipes undergo annealing, a process that entails heating the pipes to a precise temperature and gradually cooling them. This technique alleviates inner tensions, enhances the steel's ductility, and improves its resistance to corrosion. Following annealing, the pipes are subjected to a bright annealing process. This involves heating the pipes at a high temperature in a controlled atmosphere, followed by rapid cooling. As a result, the pipes acquire a sleek, lustrous, and reflective surface finish. On the contrary, annealed pickled stainless steel pipes also undergo annealing to enhance their properties. However, these pipes undergo pickling after annealing. Pickling involves immersing the pipes in an acidic solution, such as hydrochloric or sulfuric acid, to eliminate any scale, oxides, or impurities present on the steel's surface. This procedure aids in cleaning and purifying the surface, resulting in a subdued, matte finish on the pipes. In conclusion, the primary distinction between bright annealed and annealed pickled stainless steel pipes lies in their surface finishes. Bright annealed pipes possess a smooth, lustrous, and reflective finish, while annealed pickled pipes exhibit a dull, matte finish. The selection between these two finishes is contingent upon the specific requirements and aesthetics of the application.

- Q: What is the difference between 316 and 316Ti stainless steel pipes?

- The main difference between 316 and 316Ti stainless steel pipes lies in their carbon content. While both grades are highly corrosion-resistant and suitable for a wide range of applications, 316Ti contains a small amount of titanium, which gives it enhanced resistance to sensitization. Sensitization occurs when stainless steel is heated in the range of 500-900°C, causing the formation of chromium carbides that can lead to intergranular corrosion. By adding titanium, 316Ti stainless steel pipes are able to prevent the formation of these carbides by reacting with the carbon, thus maintaining the corrosion resistance of the material even when exposed to high temperatures. This makes 316Ti pipes more suitable for applications involving elevated temperatures or prolonged exposure to corrosive environments. In terms of mechanical properties, both grades exhibit similar strength and toughness. However, due to the addition of titanium, 316Ti may have slightly lower ductility compared to 316. It is important to note that the difference in carbon content between these two grades is small, typically less than 0.08%. In summary, the addition of titanium in 316Ti stainless steel pipes provides improved resistance to sensitization and intergranular corrosion, making it a preferred choice for applications involving high temperatures or corrosive environments.

- Q: How do you prevent oxidation in stainless steel pipes?

- There are several methods to prevent oxidation in stainless steel pipes. One effective way is to apply a protective coating or finish on the surface of the pipes. This can be done using various types of coatings such as paints, epoxy, or polyurethane. These coatings act as a barrier, preventing oxygen from coming into contact with the stainless steel and therefore reducing the chances of oxidation. Additionally, regular cleaning and maintenance of the pipes is crucial in preventing oxidation. It is important to remove any dirt, debris, or corrosive substances that may have accumulated on the surface of the pipes. This can be done using mild detergents or specialized cleaning agents specifically designed for stainless steel. Another preventive measure is to ensure proper ventilation in the area where the stainless steel pipes are installed. Adequate ventilation helps to minimize the presence of moisture or humidity, which can accelerate the oxidation process. Additionally, keeping the pipes dry and avoiding prolonged exposure to water or moisture is essential in preventing oxidation. Lastly, it is important to select the appropriate grade of stainless steel for the intended application. Different grades of stainless steel offer varying levels of resistance to oxidation. For example, austenitic stainless steel grades such as 304 and 316 are highly resistant to oxidation and are commonly used in applications where corrosion resistance is crucial. Overall, a combination of preventive measures such as protective coatings, regular cleaning, proper ventilation, and selecting the appropriate stainless steel grade can help effectively prevent oxidation in stainless steel pipes.

- Q: Can stainless steel pipes be used in the oil and gas industry?

- Yes, stainless steel pipes can be used in the oil and gas industry. Stainless steel pipes offer several advantages that make them suitable for use in this industry. Firstly, stainless steel has high corrosion resistance, which is crucial for withstanding the harsh environments and corrosive substances present in the oil and gas industry. This resistance to corrosion helps to prevent leaks and ensures the integrity of the pipes, promoting safety and reliability. Additionally, stainless steel pipes have excellent strength and durability, allowing them to withstand high pressures and temperatures that are often encountered in oil and gas operations. Moreover, stainless steel is non-reactive, meaning it does not contaminate the oil or gas being transported, ensuring the purity and quality of the product. Overall, the superior properties of stainless steel make it a preferred choice for oil and gas industry applications, providing a reliable and long-lasting solution.

- Q: Can stainless steel pipes be used for chemical refineries?

- Indeed, chemical refineries can utilize stainless steel pipes. Stainless steel possesses exceptional resistance to corrosion, rendering it an appropriate option for the management of diverse chemicals and corrosive substances prevalent in refineries. It provides exceptional strength, durability, and high temperature resistance, making it an ideal choice for the arduous conditions and demanding settings within chemical refineries. Moreover, stainless steel pipes are effortless to clean and maintain, a critical aspect in industries where cleanliness is of utmost importance to prevent contamination or compromise product quality. In summary, stainless steel pipes are extensively employed in chemical refineries due to their corrosion resistance, strength, and long lifespan.

- Q: How much is one ton of stainless steel pipe?

- First of all, to determine the use of your stainless steel pipe, and now mainly with 304 stainless steel and 316L stainless steel,304 moderate price, good rust resistance, suitable for daily home decoration.

- Q: What is the difference between seamless and submerged arc welded stainless steel pipes?

- The main difference between seamless and submerged arc welded stainless steel pipes lies in the manufacturing process and the resulting characteristics of the pipes. Seamless stainless steel pipes are made by piercing a solid cylindrical billet and then rolling it to form a hollow tube. This process ensures a smooth and uniform pipe with no welded seams. As a result, seamless pipes are generally considered to have higher strength and pressure resistance compared to welded pipes. They also have a more aesthetically pleasing appearance due to the absence of visible welds. On the other hand, submerged arc welded stainless steel pipes are manufactured by welding a coiled plate or strip of stainless steel using a submerged arc welding process. This involves feeding the plate or strip through a series of rollers while simultaneously welding the edges together using an electric arc submerged in a flux material. The flux protects the weld from impurities and helps maintain the integrity of the joint. The use of this welding method allows for the production of large diameter pipes that are well-suited for high-pressure applications. However, the welding process may leave visible weld seams on the surface of the pipe, which can affect its appearance and may require additional finishing processes. In terms of characteristics, seamless pipes are generally known for their superior strength, corrosion resistance, and ability to withstand high pressure and temperature. They are commonly used in industries such as oil and gas, chemical, and petrochemical, where these properties are crucial. Submerged arc welded pipes, on the other hand, are more cost-effective and are often used in applications that require large diameter pipes, such as in water transmission, structural support, and infrastructure projects. In summary, the main differences between seamless and submerged arc welded stainless steel pipes lie in the manufacturing process, resulting appearance, and specific applications. Seamless pipes are produced without any welded seams, offering higher strength and pressure resistance, while submerged arc welded pipes are cost-effective and suitable for large diameter applications.

- Q: Why is stainless steel magnetic?

- Many customers often think that the magnet adsorption of stainless steel, to verify its merits and authenticity, and do not smoke without magnetism, that is good, genuine; smokers are magnetic, is considered a fake fake. In fact, this is a very one-sided, not practical, and the wrong way to identify, I hope the following content for your help!

- Q: Can stainless steel pipes be used in high-pressure applications?

- Yes, stainless steel pipes can be used in high-pressure applications. Stainless steel is known for its strength, durability, and ability to withstand extreme pressure conditions. It is often used in industries such as oil and gas, chemical processing, and power generation, where high-pressure environments are common. Stainless steel pipes offer excellent resistance to corrosion, making them suitable for long-term use in high-pressure applications.

- Q: Are stainless steel pipelines buried in need of corrosion protection?

- In the aqueous medium such as Cl-, the localized destruction of the passive film due to acidification of the dielectric solution in the crevice (increasing of Cl- concentration, decrease in pH value) and hypoxia (oxygen concentration cell, gap hypoxia). The most fundamental is to eliminate the gap from the structure is designed to avoid the gap of the heat exchanger tube is connected with the gap at the gap on the tube plate, flange, gaskets, bolts, rivets, to take appropriate measures to prevent.

Send your message to us

ASTM A106/53 Stainless Steel Welded Tube manufacturer for oil Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 kg

- Supply Capability:

- 12000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords