stainless steel welded pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

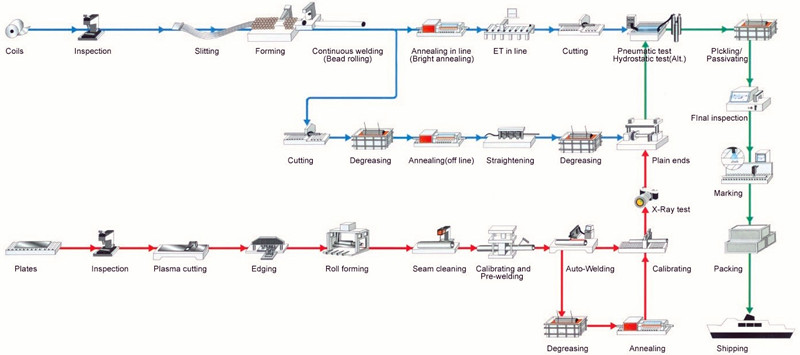

stainless steel welded pipe

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:21.3*3.73mm or others

2.Surface:4k/6k//8k

3.Length:6m or as your requirement

A series of photos

A series of pictures

- Q: Can stainless steel pipes be used for structural purposes?

- Yes, stainless steel pipes can be used for structural purposes. Stainless steel is known for its strength, durability, and resistance to corrosion, making it an excellent material for structural applications. Stainless steel pipes are commonly used in various industries such as construction, architecture, and engineering for structural support, as well as for conveying fluids and gases. They can withstand heavy loads, extreme temperatures, and harsh environmental conditions, making them suitable for a wide range of structural applications. Additionally, stainless steel pipes are available in different grades, sizes, and thicknesses, allowing for customization to meet specific structural requirements.

- Q: How can stainless steel and copper pipe be welded?

- First, try the test before burning. The brass is directly burned to the stainless steel tube. First feel the heat and see what the stainless steel likes to adhere toWhen stainless steel is not red, copper is not adheredWhen stainless steel is red, do not stick copperOnly when stainless steel is red, copper paste is preferredTherefore, when welding, we must master the size of the furnace, thin and thin pipe, fire should be adjusted to small crude pipe, on the contrary, they feel the proper heat

- Q: Are stainless steel pipes fire-resistant?

- Indeed, fire resistance is a characteristic possessed by stainless steel pipes. Renowned for its elevated melting point and exceptional fire resistance, stainless steel is a secure material choice for numerous purposes, including the construction of pipes. With its incapability to readily ignite or facilitate the expansion of flames, stainless steel ensures safety in various applications. Moreover, stainless steel pipes exhibit remarkable durability and strength even when exposed to high temperatures, assuring an additional layer of safety in environments susceptible to fires.

- Q: Are stainless steel pipes suitable for geothermal applications?

- Indeed, geothermal applications can benefit greatly from the use of stainless steel pipes. Geothermal systems rely on harnessing the earth's natural geothermal energy, which often necessitates the conveyance of hot fluids like water or steam. When it comes to this purpose, stainless steel pipes are an ideal selection due to their exceptional strength, resistance to corrosion, and ability to endure high temperatures. They possess the capability to withstand the demanding conditions typically found in geothermal environments, including the presence of acidic or corrosive fluids, while exhibiting a lower likelihood of degradation over time compared to other materials. Furthermore, stainless steel pipes boast excellent thermal conductivity, thereby ensuring the efficient transfer of heat in geothermal applications. All in all, one can confidently consider stainless steel pipes as a dependable and long-lasting choice for geothermal systems.

- Q: How do you calculate the flow rate of fluid through stainless steel pipes?

- To determine the flow rate of fluid through stainless steel pipes, one can utilize either the Bernoulli's equation or the Darcy-Weisbach equation. These equations incorporate several factors, including the pipe's diameter, length, fluid viscosity, and the pressure difference between both ends. 1. Bernoulli's equation, which hinges on the principle of energy conservation, establishes a relationship between pressure, velocity, and elevation along the fluid's path. The equation is as follows: P1 + 0.5 * ρ * V1^2 + ρ * g * h1 = P2 + 0.5 * ρ * V2^2 + ρ * g * h2 Here: - P1 and P2 denote the pressures at the pipe's two ends. - ρ represents the fluid's density. - V1 and V2 denote the fluid velocities at each end of the pipe. - g signifies the acceleration caused by gravity. - h1 and h2 refer to the fluid elevations at the respective ends. By rearranging the equation and solving for either V1 or V2, one can calculate the fluid's velocity. Multiplying this velocity by the pipe's cross-sectional area yields the flow rate. 2. The Darcy-Weisbach equation, widely employed to calculate pressure drop or head loss due to frictional resistance in a pipe, is expressed as follows: ΔP = f * (L / D) * (ρ * V^2 / 2) Here: - ΔP represents the pressure drop between the pipe's two ends. - f denotes the Darcy friction factor, which relies on the Reynolds number and pipe roughness. - L corresponds to the pipe's length. - D signifies the pipe's diameter. - ρ represents the fluid's density. - V denotes the fluid's velocity. By rearranging the equation and solving for V, one can compute the fluid's velocity. Multiplying this velocity by the pipe's cross-sectional area provides the flow rate. It is crucial to acknowledge that these equations offer theoretical calculations, and actual flow rates may deviate due to additional factors such as pipe roughness, fittings, and bends. Consequently, it is advisable to account for these factors, conduct experiments, or consult industry standards for more precise calculations.

- Q: Can stainless steel pipes be used in the oil and gas industry?

- Yes, stainless steel pipes can be used in the oil and gas industry. Stainless steel is highly resistant to corrosion and can withstand high pressure and extreme temperature conditions, making it a suitable material for transporting oil and gas. It also has excellent durability and reliability, making it a preferred choice for various applications in the industry.

- Q: Are stainless steel pipes suitable for sanitary applications?

- Stainless steel pipes are indeed a great fit for sanitary purposes. The remarkable corrosion resistance, durability, and hygienic qualities of stainless steel make it the perfect option for settings that call for cleanliness and sanitation, like food processing plants, pharmaceutical facilities, and hospitals. It's worth mentioning that stainless steel pipes are non-porous, meaning they don't absorb or retain bacteria, contaminants, or odors. Moreover, they are effortless to clean and maintain, ensuring the utmost level of hygiene. Furthermore, stainless steel pipes can endure high temperatures and pressures, making them well-suited for a vast array of sanitary applications.

- Q: How do stainless steel pipes compare to carbon fiber pipes?

- Stainless steel pipes and carbon fiber pipes have their own unique characteristics and are used in different applications. Stainless steel pipes are known for their durability and strength. They are highly resistant to corrosion and can withstand high temperatures and pressures. This makes them suitable for various industries such as oil and gas, chemical, and construction. Stainless steel pipes have a longer lifespan and can handle heavy loads, making them a reliable choice for many applications. However, stainless steel pipes are relatively heavy and may require additional support structures. On the other hand, carbon fiber pipes are lightweight and have a high strength-to-weight ratio. They are made from carbon fibers embedded in a resin matrix, resulting in a strong and rigid material. Carbon fiber pipes are commonly used in industries such as aerospace, automotive, and sports equipment. The lightweight nature of carbon fiber pipes allows for increased fuel efficiency in vehicles and improved performance in sports equipment. However, carbon fiber pipes are more expensive than stainless steel pipes and may not be as resistant to extreme temperatures or corrosive environments. In summary, stainless steel pipes are known for their durability and resistance to corrosion, making them suitable for heavy-duty applications. Carbon fiber pipes, on the other hand, are lightweight and offer high strength-to-weight ratio, making them ideal for applications where weight reduction is critical. The choice between stainless steel and carbon fiber pipes ultimately depends on the specific requirements of the application and the trade-offs between cost, weight, and performance.

- Q: Are stainless steel pipes resistant to pitting and crevice corrosion?

- Yes, stainless steel pipes are generally resistant to pitting and crevice corrosion due to their high chromium content, which forms a protective oxide layer on the surface, preventing corrosion. However, the resistance can vary depending on the specific grade of stainless steel and the environment in which the pipes are used.

- Q: How do stainless steel pipes compare to PEX pipes?

- Different plumbing systems require different characteristics and applications, making stainless steel pipes and PEX pipes suitable options. Stainless steel pipes are renowned for their durability and strength, making them ideal for water supply systems, especially in areas with aggressive water conditions. Their resistance to corrosion and ability to withstand high pressure and temperature make them suitable for both residential and commercial use. Moreover, stainless steel pipes are fire-resistant and have a long lifespan, requiring minimal maintenance and offering cost-effectiveness in the long term. On the other hand, PEX pipes, composed of cross-linked polyethylene, provide flexibility and easy installation. These pipes are highly resistant to freezing and bursting, making them a great choice for cold-climate regions. Their capacity to expand and contract reduces the risk of leaks or bursts caused by temperature changes. Additionally, PEX pipes are corrosion-resistant, eliminating the need for costly and time-consuming maintenance. They also dampen noise and vibration, providing a quieter alternative to metal pipes. When making a decision between stainless steel pipes and PEX pipes, it is crucial to consider specific plumbing requirements, budget, and local building codes. While stainless steel pipes excel in durability and strength, PEX pipes offer flexibility and ease of installation. Ultimately, the choice depends on the unique needs of the plumbing system and the preferences of the homeowner or plumbing professional.

Send your message to us

stainless steel welded pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords