Seamless Stainless Steel Pipes and Stainless Steel Flat Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

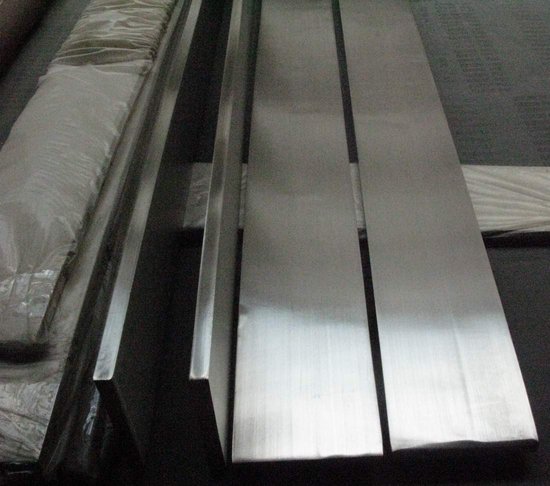

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade:

1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. Cherryliu@okorder.com |

- Q:Can stainless steel pipes be buried in soil?

- Yes, stainless steel pipes can be buried in soil. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions of being buried underground, making it a suitable choice for various underground applications such as drainage, sewage, and water supply systems.

- Q:Are stainless steel pipes suitable for chemical reactors?

- Yes, stainless steel pipes are suitable for chemical reactors. Stainless steel is known for its excellent corrosion resistance properties, making it an ideal choice for handling various chemicals and acids in a reactor system. Additionally, stainless steel pipes offer high strength, durability, and heat resistance, ensuring safe and efficient operation in chemical processes.

- Q:Are stainless steel pipes suitable for paper and pulp industry?

- Indeed, stainless steel pipes prove to be exceptionally well-suited for employment in the paper and pulp industry. This particular industry involves the manipulation of various chemicals that are corrosive in nature, as well as exposure to high temperatures and conditions of elevated pressure. Stainless steel pipes, with their remarkable resistance to corrosion, heat, and pressure, emerge as the ideal choice for this industry. The level of resistance displayed by stainless steel pipes against chemicals like chlorine dioxide and bleaching agents, along with other corrosive substances used in the paper and pulp industry, is notably high. This resistance guarantees that the pipes will not undergo corrosion or deterioration over time, thereby preventing leakage and ensuring the integrity of the entire piping system. Moreover, stainless steel pipes exhibit exceptional heat resistance, enabling them to withstand the high temperatures encountered during the paper and pulp production process. They can effortlessly accommodate both hot and cold liquids without experiencing any significant impact on their performance or structural integrity. Furthermore, the strength and durability of stainless steel pipes are commendable, rendering them capable of effectively managing the frequently encountered high-pressure conditions in the paper and pulp industry. These pipes can endure the force and stress exerted by the fluids being transported, thereby guaranteeing the dependability and longevity of the piping system. Additionally, stainless steel pipes are easy to clean and maintain, a crucial feature in industries where strict hygiene and sanitation requirements prevail, such as the paper and pulp industry. The smooth surface of these pipes impedes the accumulation of debris and contaminants, minimizing the risk of contamination and ensuring the overall quality of the final product. To conclude, the suitability of stainless steel pipes for the paper and pulp industry can be attributed to their resistance to corrosion, heat, and pressure. These pipes offer a resilient, dependable, and hygienic piping solution, making them an excellent choice for this particular industry.

- Q:How is stainless steel pipe manufactured?

- Stainless steel pipe is manufactured through a process called seamless or welded pipe manufacturing. In the seamless method, a solid cylindrical billet of stainless steel is heated and pierced to form a hollow tube. This tube is then elongated and rolled to the desired diameter and thickness. Welded stainless steel pipe, on the other hand, involves the joining of two or more stainless steel plates or coils through a welding process. The resulting pipe is then further processed and finished to meet specific industry standards and requirements.

- Q:Ask experts, 304 stainless steel pipe why rust?

- Stainless steel is not easy to rust and has a lot to do with the composition of stainless steel. In addition to iron, stainless steel contains chromium, nickel, aluminum, silicon and so on. General stainless steel chromium content is generally not less than 12%, high even up to 18%. Steel added elements such as chromium, can change the performance of the steel, such as the molecular structure of steel more uniform on the surface of the steel is more easily to form a layer of dense oxide protective film, thereby greatly improving the ability of corrosion-resistant stainless steel. Therefore, stainless steel can resist fire, water, acid, alkali and various solutions to its corrosion, not rust. The scientists found that the internal structure of the steel is more uniform, various components more closely linked to the corrosion of the more difficult the invasion, also attached to the surface with a layer of oxide film, like iron and steel to wear armor, was not naturally easy to rust.

- Q:Can stainless steel pipes be insulated with ceramic?

- Yes, stainless steel pipes can be insulated with ceramic. Ceramic insulation is commonly used in industrial applications where high temperatures are involved. Ceramic insulation provides excellent heat resistance and thermal insulation properties. It can withstand extreme temperatures and is highly effective in reducing heat transfer. Ceramic insulation is often used to insulate pipes, tanks, furnaces, and other equipment in various industries. When applied to stainless steel pipes, ceramic insulation helps to maintain the temperature of the fluid inside the pipes and prevents heat loss or gain. It also provides protection against corrosion and mechanical damage. Overall, ceramic insulation is a suitable option for insulating stainless steel pipes in a wide range of applications.

- Q:Are stainless steel pipes suitable for food and beverage processing?

- Stainless steel pipes are highly suitable for food and beverage processing due to their unique properties and benefits. The popularity of stainless steel in the food and beverage industry stems from its corrosion resistance, making it ideal for environments with acids, chemicals, and moisture. This ensures the pipes remain hygienic, rust-free, and contamination-free, guaranteeing the safety and quality of the processed food or beverage. Moreover, stainless steel pipes have a smooth surface that prevents the adherence of bacteria, dirt, or contaminants, making cleaning and sanitization easier and more effective, reducing the risk of cross-contamination. Additionally, stainless steel pipes possess high heat resistance, enabling them to withstand extreme temperatures without warping or deforming. This quality makes them suitable for various food processing applications, including pasteurization and sterilization. Furthermore, stainless steel is non-reactive, meaning it does not interact with the food or beverage being processed. This ensures that the taste, odor, and overall quality of the final product remain uncompromised. In conclusion, stainless steel pipes are an excellent choice for food and beverage processing due to their corrosion resistance, ease of cleaning, high heat resistance, and non-reactive nature. These qualities make them a reliable and safe option for maintaining the hygiene and quality standards required in the industry.

- Q:Can stainless steel pipes be threaded?

- Yes, stainless steel pipes can be threaded. Threading is a common process used to create a screw-like groove on the outside of the pipe, allowing it to be connected to other fittings or components. Stainless steel is a versatile material that can be threaded using various methods, such as cutting or rolling, to accommodate different applications and industry standards.

- Q:Can stainless steel pipes handle high temperatures?

- Yes, stainless steel pipes are capable of handling high temperatures.

- Q:Can stainless steel pipes be used for breweries?

- Yes, stainless steel pipes are commonly used in breweries due to their corrosion resistance, durability, and ability to maintain the purity of the contents.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei,China |

| Year Established | 2009 |

| Annual Output Value | Above US$1 million |

| Main Markets | Asia, Middle East,America |

| Company Certifications | CE, CCC, ISO90001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 0.3 |

| No.of Employees in Trade Department | 4 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Lower |

Send your message to us

Seamless Stainless Steel Pipes and Stainless Steel Flat Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords