Stainless Steel Pipes - Large Diameter for Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure :

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

Main Features :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

Specification:

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

FAQ :

A. How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

B. How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

C.Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

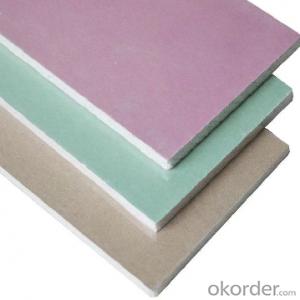

Product image:

Company Information:

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

- Q:What is the difference between electropolished and passivated stainless steel pipes?

- Electropolished and passivated stainless steel pipes are both surface treatments used to enhance the corrosion resistance and aesthetic appearance of stainless steel. However, there are some key differences between the two processes. Electropolishing is an electrochemical process that selectively removes a thin layer of material from the stainless steel surface. This process helps to remove impurities, contaminants, and embedded particles, resulting in a smooth and clean surface. Electropolishing also improves the microfinish of the stainless steel, reducing surface roughness and enhancing the overall appearance. This process can also improve the corrosion resistance of stainless steel by creating a passive chromium oxide layer on the surface. On the other hand, passivation is a chemical process that involves the application of an acid-based solution to the stainless steel surface. This solution helps to remove iron contaminants and other foreign substances from the surface, leaving behind a clean and passive layer of chromium oxide. Passivation helps to enhance the corrosion resistance of stainless steel by promoting the formation of a stable and protective oxide layer. In summary, electropolishing is an electrochemical process that removes a thin layer of material to create a smooth and clean surface, while passivation is a chemical process that removes contaminants and promotes the formation of a protective oxide layer. Both processes contribute to improving the corrosion resistance and aesthetics of stainless steel pipes, but they differ in the method used to achieve these results.

- Q:What are the common shapes of stainless steel pipes?

- Stainless steel pipes come in various shapes that are widely utilized across different industries. These shapes comprise of round pipes, square pipes, rectangular pipes, and oval pipes. Round pipes rank among the most prevalent shapes and find extensive use in diverse applications. They are primarily employed for fluid and gas transportation, as well as the conveyance of other materials. Furthermore, round pipes are well-suited for structural purposes like handrails, scaffolding, and support beams. Square pipes possess a square cross-section and are commonly employed in construction projects, architectural designs, and furniture manufacturing. They offer a sleek and contemporary appearance, often utilized for framing structures, manufacturing shelves, and creating decorative elements. Rectangular pipes possess a rectangular cross-section and are frequently utilized in the construction, engineering, and manufacturing industries. They are often employed in building frameworks, manufacturing gates, fences, and various structural components. Oval pipes possess an elliptical or oval shape and are used in applications where aesthetics play a significant role. They are a popular choice in architectural designs, the automotive industry, and decorative applications. In conclusion, the selection of stainless steel pipe shape depends on the specific requirements of the application and desired aesthetics. Each shape offers distinct advantages and is chosen based on factors such as strength, durability, ease of fabrication, and overall design requirements.

- Q:Can stainless steel pipes be threaded with NPT threads?

- Yes, stainless steel pipes can be threaded with NPT (National Pipe Thread) threads. NPT is a widely used standard for pipe threads in the United States, and it is suitable for both stainless steel and other materials. However, it is important to note that stainless steel has a higher strength and hardness compared to other materials, which may require more care and attention during the threading process. Additionally, it is recommended to use lubricants or cutting fluids specifically designed for stainless steel to ensure a smooth and accurate threading operation.

- Q:What is the difference between seamless and welded stainless steel pipes?

- The main difference between seamless and welded stainless steel pipes lies in their manufacturing process. Seamless pipes are made from a solid cylindrical billet, which is heated and pierced to form a hollow tube. This process ensures a smooth and uniform surface, with no joints or seams. On the other hand, welded pipes are made by rolling a flat strip of steel into a cylindrical shape and then welding the edges together. This results in a visible seam along the length of the pipe. While seamless pipes offer higher strength and corrosion resistance, welded pipes are more cost-effective and suitable for less demanding applications.

- Q:What are the different types of stainless steel pipe flanges?

- Various types of stainless steel pipe flanges are available to meet specific application needs and requirements. Some commonly used types include: 1. Weld Neck Flanges: These flanges have a tapered hub and are welded to the pipe, offering exceptional strength and durability. They are suitable for high-pressure and high-temperature applications. 2. Slip-On Flanges: These flanges slide onto the pipe and are then welded in place, providing a secure connection. They are easy to install and commonly used in low-pressure and non-critical applications. 3. Socket Weld Flanges: These flanges have a socket-like end that fits over the pipe and is then welded, ensuring leak resistance. They are used for smaller pipes. 4. Threaded Flanges: These flanges can be screwed onto the pipe due to their internal threads. They are easy to install and remove, making them suitable for low-pressure applications. 5. Lap Joint Flanges: These flanges consist of a stub end and a loose backing flange, allowing for frequent dismantling or precise alignment. 6. Blind Flanges: These solid flanges have no bore and are perfect for closing off the end of a pipe. They are commonly used in piping systems that require periodic inspection or cleaning. 7. Orifice Flanges: These flanges have concentric or eccentric holes to measure fluid flow rate. They find applications in flow measurement. 8. Spectacle Blind Flanges: These flanges combine a blind flange with a spacer and are used to separate pipe system sections. They can be easily removed for maintenance or repair. It is crucial to choose the appropriate stainless steel pipe flange type based on specific application requirements, including pressure, temperature, and fluid compatibility.

- Q:Do stainless steel pipes require insulation?

- Yes, stainless steel pipes require insulation. Insulation helps to prevent heat loss or gain, reduces condensation, and maintains the temperature of the fluid inside the pipes.

- Q:Can stainless steel pipes be used for geothermal systems?

- Yes, stainless steel pipes can be used for geothermal systems. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for the harsh conditions of a geothermal system. Geothermal systems involve the transfer of heat from the earth's core to the surface, which often requires the circulation of hot water or steam. Stainless steel pipes can effectively handle the high temperatures and pressure associated with geothermal systems without corroding or degrading over time. Additionally, stainless steel is resistant to scaling and mineral build-up, which can be common in geothermal systems. Overall, the use of stainless steel pipes ensures the longevity and efficiency of geothermal systems.

- Q:Can stainless steel pipes be used for chemical processing plants?

- Yes, stainless steel pipes can be used for chemical processing plants. Stainless steel is a popular choice for various industrial applications, including chemical processing, due to its excellent corrosion resistance properties. Chemical processing plants deal with various corrosive substances, such as acids, alkalis, and solvents, which can cause damage to ordinary steel pipes. However, stainless steel pipes are highly resistant to corrosion, making them suitable for handling aggressive chemicals and ensuring the safety and reliability of the plant. Additionally, stainless steel pipes can withstand high temperatures, pressure, and mechanical stresses, making them a durable and long-lasting choice for chemical processing plants.

- Q:How do you prevent freezing in stainless steel pipes?

- There are several measures that can be taken to prevent freezing in stainless steel pipes: 1. Insulating the pipes is a highly effective method. You can wrap the pipes with insulation sleeves or use foam pipe insulation. This will help maintain the pipes' temperature and prevent them from becoming too cold. 2. Heat tracing is another effective technique. This involves installing electric heat cables along the pipes' length. These cables generate heat and keep the pipes warm, thus preventing freezing. 3. It is crucial to maintain a constant temperature in the area where the stainless steel pipes are located. If the pipes are exposed to extreme cold temperatures, make sure to heat the area properly. You can use space heaters or insulate the surrounding walls to retain heat. 4. Keeping the water flowing through the pipes is essential. Moving water is less likely to freeze compared to stagnant water. If the pipes are used for water transportation, ensure that the water keeps flowing, even if it's just a small trickle. This continuous flow will help prevent freezing. 5. Check for any air leaks or drafts around the stainless steel pipes. Cold air entering the space can cause the pipes to freeze. Seal any gaps or cracks with weatherstripping or caulk to prevent cold air from entering. 6. Monitoring the temperature in the area where the stainless steel pipes are located is important. Install a thermometer to keep track of the temperature. This will help identify any potential freezing risks and allow you to take necessary precautions in advance. By implementing these preventive measures, you can effectively safeguard your stainless steel pipes from freezing and avoid potential damage.

- Q:What is the difference between 904L and 316L stainless steel pipes?

- The main difference between 904L and 316L stainless steel pipes lies in their composition and properties. 904L stainless steel is a high alloy austenitic stainless steel with higher levels of chromium, nickel, and molybdenum, making it highly resistant to corrosion in various environments, including harsh industrial and marine conditions. On the other hand, 316L stainless steel is a lower alloy austenitic stainless steel that contains less chromium, nickel, and molybdenum, making it less resistant to corrosion compared to 904L. Therefore, 904L stainless steel pipes are typically preferred in applications that require exceptional corrosion resistance, while 316L stainless steel pipes are suitable for general-purpose applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Pipes - Large Diameter for Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 5000 m.t./month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords