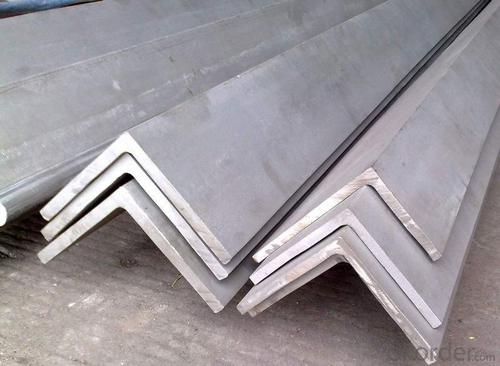

Best Quality for Stainless Steel Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2MT m.t.

- Supply Capability:

- 5000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Details of Stainless Steel Angle:

Size mm | |

Width | Thickness |

25 x 25 | 3 4 5 |

30 x 30 | 3 4 5 |

40 x 40 | 3 4 5 6 |

50 x 50 | 4 5 6 |

60 x 60 | 5 6 7 |

65 x 65 | 5 6 7 |

70 x 70 | 6 7 8 |

75 x 75 | 6 7 8 9 |

80 x 80 | 7 8 9 10 |

100 x 100 | 8 9 10 12 |

Tolerance:GB4227, ASTM A276/A 484M, EN10056/DIN 1028 | |

Features of Stainless Steel Angle:

1. All products are made of high-quality imported raw materials.

2. Our products are certified by ISO9001:2008 authentication quality systems.

3. We are nominated as the AAA enterprise by Jiangsu government.

4. Quickest and most efficient Response to Your Enquiry.

5.Selected quality material

6.Finely processed

7.Prime quality&Bottom price

8.Complete in specifications

9.Abundant stock

Application of Stainless Steel Angle

Stainless steels of various kinds are used in thousands of applications. The following gives a flavour of the full range:

1.Domestic --- cutlery, sinks, saucepans, washing machine drums, microwave oven liners, razor blades

2.Architectural/Civil Engineering---- cladding, handrails, door and window fittings, street furniture, structural sections,reinforcement bar, lighting columns, lintels, masonry supports

3.Transport --- exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles

4.Chemical/Pharmaceutical --- pressure vessels, process piping.

5.Oil and Gas ---platform accommodation, cable trays, subsea pipelines.

6.Medical ---Surgical instruments, surgical implants, MRI scanners.

7.Food and Drink ---Catering equipment, brewing, distilling, food processing.

8.Water ---Water and sewage treatment, water tubing, hot water tanks.

9.General ----springs, fasteners (bolts, nuts and washers), wire.

- Q: Can stainless steel angles be used in architectural canopies?

- Yes, stainless steel angles can be used in architectural canopies. Stainless steel is a popular material choice in architectural applications due to its durability, resistance to corrosion, and aesthetic appeal. Stainless steel angles provide structural support and can be easily incorporated into the design of canopies, ensuring stability and longevity.

- Q: What are the strength properties of stainless steel angles?

- Stainless steel angles possess several strength properties that make them highly desirable in various applications. Firstly, stainless steel angles have excellent tensile strength, which refers to their ability to withstand pulling or stretching forces without breaking or deforming. This high tensile strength makes stainless steel angles suitable for applications that require resistance to heavy loads or forces. Additionally, stainless steel angles exhibit good yield strength, which is the maximum stress a material can withstand without undergoing permanent deformation. This property is crucial in structural applications where the angles are subjected to bending or twisting forces. The high yield strength of stainless steel angles ensures their durability and structural integrity even under extreme conditions. Furthermore, stainless steel angles have exceptional corrosion resistance, thanks to their high chromium content. This property allows them to resist rust, tarnish, and other forms of corrosion, making them suitable for use in harsh environments, such as marine or chemical industries. The corrosion resistance of stainless steel angles ensures their longevity and maintains their strength properties over time. Moreover, stainless steel angles have excellent heat resistance properties. They can withstand high temperatures without losing their structural integrity or strength. This makes them suitable for applications that involve exposure to heat, such as industrial ovens, furnaces, or exhaust systems. Lastly, stainless steel angles possess good impact strength, enabling them to absorb energy without breaking or fracturing. This property is essential in applications where the angles may encounter sudden or repeated impacts, such as in construction or automotive industries. In summary, stainless steel angles exhibit high tensile and yield strength, excellent corrosion and heat resistance, as well as good impact strength. These strength properties make them a preferred choice in various industries where durability, reliability, and longevity are vital.

- Q: Can stainless steel angles be used in food processing?

- Indeed, stainless steel angles are applicable for food processing purposes. Owing to its remarkable resistance to corrosion and its hygienic attributes, stainless steel has become a favored material in the food industry. Its exceptional ability to withstand rust, staining, and chemical harm renders it appropriate for direct contact with food and cleaning agents. In the realm of constructing food processing equipment, such as conveyor systems, mixing tanks, storage tanks, and food preparation surfaces, stainless steel angles are frequently employed. The sleek and easily cleanable surface of these angles serves to hinder the proliferation of bacteria, thus making it a secure and sanitary choice for food processing applications.

- Q: 2520 stainless steel main properties

- 2520 stainless steel with 2520 stainless steel, 2520 stainless steel rods, 2520 stainless steel tube, 2520 stainless steel angle steel, 2520 stainless steel, round steel, stainless steel plate, stainless steel rods, stainless steel tube, can work for a long time under the high temperature of 1250 degrees.

- Q: Are stainless steel angles suitable for the production of street furniture?

- Stainless steel angles are indeed appropriate for the manufacturing of street furniture. Due to its remarkable durability and resistance to corrosion, stainless steel is perfect for outdoor use. Given that street furniture, including benches, bollards, and trash cans, is constantly exposed to diverse weather conditions and heavy utilization, it is prone to wear and tear. Nevertheless, stainless steel angles provide exceptional strength and endurance, guaranteeing that the street furniture can endure these challenging circumstances and uphold its structural integrity in the long run. Moreover, stainless steel possesses an appealing and contemporary appearance, which has made it a popular preference for street furniture that enhances the visual appeal of public spaces.

- Q: What are the standard lengths of stainless steel angles?

- The lengths of stainless steel angles can differ based on the supplier and project specifications. Nevertheless, stainless steel angles are commonly available in lengths ranging from 20 to 40 feet, usually in increments of 5 feet. It should be emphasized that certain suppliers may also provide customized lengths to fulfill customer requirements.

- Q: How do stainless steel angles contribute to seismic resistance?

- Stainless steel angles are versatile structural components that play a crucial role in enhancing the seismic resistance of buildings and structures. They contribute to seismic resistance in several ways. Firstly, stainless steel angles are known for their high strength and ductility, which allows them to withstand the dynamic forces generated during an earthquake. Their exceptional mechanical properties enable them to resist bending, twisting, and shearing forces, providing structural stability and integrity to the building. Moreover, stainless steel angles offer excellent corrosion resistance, which is a significant advantage in seismic regions prone to high levels of moisture and humidity. By maintaining their structural integrity over time, stainless steel angles ensure the long-term stability and performance of the building during seismic events. Additionally, stainless steel angles can be easily welded and fabricated, allowing for efficient construction processes. This versatility enables engineers to design and construct seismic-resistant systems more effectively, incorporating features such as moment-resisting frames, braced frames, or other seismic-resistant structural systems. Furthermore, stainless steel angles have a high fire resistance, which is another critical factor in seismic design. In the event of a seismic event followed by a fire, stainless steel angles can withstand high temperatures for more extended periods without losing their structural strength. This characteristic ensures that the building remains stable and safe for occupants and emergency responders. Lastly, stainless steel angles provide several design opportunities due to their aesthetic appeal and architectural versatility. Architects and designers can incorporate stainless steel angles into the building's overall design, creating visually appealing structures that also meet the required seismic resistance standards. In conclusion, stainless steel angles contribute to seismic resistance by providing high strength, ductility, corrosion resistance, fire resistance, and design flexibility. These properties allow them to withstand the dynamic forces generated during an earthquake, ensuring the structural stability and integrity of buildings in seismic regions.

- Q: Can stainless steel angles be used in chemical processing equipment?

- Yes, stainless steel angles can be used in chemical processing equipment. Stainless steel is widely used in the chemical industry due to its excellent corrosion resistance properties. Stainless steel angles are specifically designed to provide structural support and stability in various applications, including chemical processing equipment. The high resistance to corrosion, heat, and chemicals make stainless steel angles suitable for use in environments where exposure to corrosive substances is common. Additionally, stainless steel angles offer good mechanical strength, durability, and hygiene, making them ideal for chemical processing equipment that requires a high level of reliability and cleanliness.

- Q: How do you calculate the load-bearing capacity of stainless steel angles?

- The load-bearing capacity of stainless steel angles can be calculated using a formula that takes into account various factors such as the dimensions of the angle, the material properties of the stainless steel, and the applied load. One common method for calculating the load-bearing capacity is to use the Euler's formula for column buckling. This formula considers the length, moment of inertia, and modulus of elasticity of the angle to determine the critical buckling load. Another method is to calculate the maximum bending moment that the angle can withstand before it reaches its yield strength. This can be determined by considering the section modulus of the angle and the applied load. It is important to note that these calculations are based on assumptions and simplifications, and actual load-bearing capacity may be affected by other factors such as the fabrication quality, surface conditions, and the presence of any additional loads or stresses. To accurately calculate the load-bearing capacity of stainless steel angles, it is recommended to consult engineering handbooks, industry standards, or consult with a structural engineer who can consider all the relevant factors and provide a precise analysis.

- Q: What are the different types of stainless steel angle profiles?

- Some of the different types of stainless steel angle profiles include equal leg angles, unequal leg angles, rounded inside corners, and sharp inside corners. These profiles vary in their dimensions and are used for various applications in construction, manufacturing, and architectural industries.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for Stainless Steel Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2MT m.t.

- Supply Capability:

- 5000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords