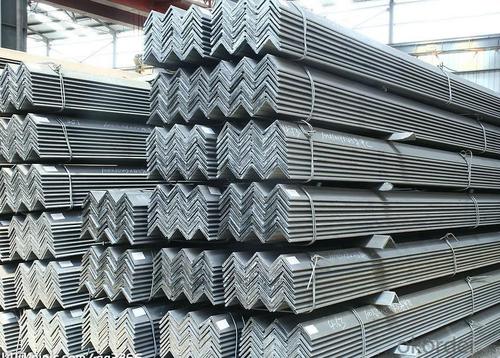

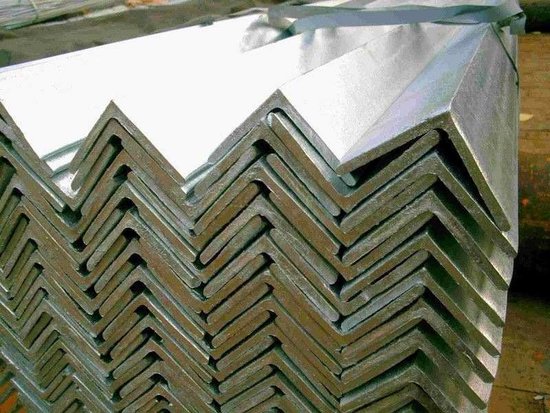

430 Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Angles

1.Grade: SS200,300,400 series

2.Size: 25×25×3 mm-100×100×10mm

3.Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package:Standard Export Packing, or put into wooden boxes according to your

requirement

10. Application: Construction, Marine, Industry and so on

|

Name |

Stainless Steel Angles | ||||||

|

Standard |

ASTM A554, A312, A249, A269 and A270 | ||||||

|

Material Grade |

304,316,201,202, 316L,430 | ||||||

|

Length |

6m or as customers' request | ||||||

|

Tolerance |

a) thickness: +/-0. 15mm | ||||||

|

| |||||||

|

b) Length:+/-4. 5mm - 0mm | |||||||

|

Surface |

180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

|

Application |

Decoration construction, upholstery, industry instruments | ||||||

|

Test |

Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

|

Chemical Composition of Material |

Composition

Material |

201 |

202 |

304 |

316L |

430 | |

|

C |

≤0.15 |

≤0.15 |

≤0.08 |

≤0.08 |

≤0.12 | ||

|

Si |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 | ||

|

Mn |

5.5-7.5 |

7.5-10 |

≤2.00 |

≤2.00 |

≤1.00 | ||

|

P |

≤0.06 |

≤0.06 |

≤0.045 |

≤0.045 |

≤0.040 | ||

|

S |

≤0.03 |

≤0.03 |

≤0.030 |

≤0.030 |

≤0.030 | ||

|

Cr |

16-18 |

17-19 |

18-20 |

16-18 |

16-18 | ||

|

Ni |

3.5-5.5 |

4-6 |

8-10.5 |

10-14 |

| ||

|

Mo |

|

|

|

2.0-3.0 |

| ||

|

Mechanical Property |

Material Item |

201 |

202 |

304 |

316L | ||

|

Tensile Strength |

≥535 |

≥520 |

≥520 |

≥520 | |||

|

Yield Strength |

≥245 |

≥205 |

≥205 |

≥205 | |||

|

Extension |

≥30% |

≥30% |

≥35% |

≥35% | |||

|

Hardness (HV) |

<253 |

<253 |

<200 |

<200 | |||

- Q: What are the common grades of stainless steel angles?

- The common grades of stainless steel angles include 304/304L, which is the most widely used grade, as well as 316/316L, which offers higher corrosion resistance.

- Q: Can stainless steel angles be used for framing?

- Yes, stainless steel angles can be used for framing. Stainless steel is known for its strength, durability, and corrosion resistance, making it a suitable material for various construction applications. Stainless steel angles, with their L-shaped profile, provide structural support and stability when used in framing projects. They can be used to create frames for doors, windows, cabinets, shelving units, and other structural elements. Stainless steel angles offer excellent load-bearing capacity and can withstand heavy weights, making them ideal for framing applications that require strength and durability. Additionally, stainless steel angles have a sleek and modern appearance, adding an aesthetic appeal to any framing project.

- Q: What are the different types of corrosion-resistant coatings for stainless steel angles?

- There are several different types of corrosion-resistant coatings available for stainless steel angles. Some common options include electroplating with materials like zinc or chromium, applying a powder coating or liquid paint, using a ceramic or porcelain enamel coating, or applying a galvanized coating. Each of these coatings provides a protective layer that helps to prevent corrosion and extend the lifespan of the stainless steel angles.

- Q: What is the difference between 316 and 316H stainless steel angles?

- The carbon content sets 316 and 316H stainless steel angles apart. While both alloys share the same levels of chromium, nickel, and molybdenum, 316H stainless steel angles have a greater amount of carbon compared to 316 stainless steel angles. The elevated carbon content in 316H stainless steel angles bestows them with heightened strength and resistance to deformation at high temperatures. Consequently, 316H is better suited for applications where elevated temperatures are of concern, such as in the petrochemical, chemical, and power generation industries. Conversely, 316 stainless steel angles find common use in general applications that prioritize high resistance against corrosion. Its exceptional corrosion and pitting resistance make it widely employed in marine environments, food processing equipment, and medical devices. To summarize, the disparity between 316 and 316H stainless steel angles lies in their carbon content. 316H possesses a greater amount of carbon, enhancing its strength and resistance to deformation at high temperatures, while 316 is favored for its extraordinary resistance to corrosion. The choice between the two hinges on the specific requirements of the intended application.

- Q: What are the surface finishes available for stainless steel angles?

- Some of the surface finishes available for stainless steel angles include mill finish, brushed finish, mirror finish, and satin finish.

- Q: How do stainless steel angles contribute to the overall versatility of a structure?

- Stainless steel angles play a crucial role in enhancing the overall versatility of a structure in several ways. Firstly, stainless steel angles provide structural support and stability to various components of a building or structure. They are commonly used to reinforce and strengthen corners, edges, and joints, ensuring the overall stability and durability of the structure. Secondly, stainless steel angles offer flexibility in design and construction. Due to their unique L-shaped profile, they can be easily shaped and customized to fit any specific requirement and architectural design. This allows architects and engineers to create intricate and complex structures with ease, while maintaining structural integrity. Moreover, stainless steel angles are highly resistant to corrosion, making them ideal for use in both indoor and outdoor environments. Their corrosion resistance properties enable them to withstand exposure to harsh weather conditions, chemicals, and other environmental factors, ensuring the longevity and durability of the structure. Additionally, stainless steel angles are fire-resistant, making them a safe choice for structural applications. In the event of a fire, stainless steel angles can maintain their structural integrity and prevent the spread of flames, ensuring the safety of occupants and minimizing damage to the structure. Furthermore, stainless steel angles are low-maintenance materials. They require minimal upkeep and are easy to clean, reducing the overall maintenance costs of a structure. This makes them a cost-effective choice for long-term usage. Lastly, stainless steel angles offer aesthetic appeal to structures. Their sleek and modern appearance adds a touch of sophistication to any design, making them a popular choice in architectural and interior applications. They can be polished, brushed, or finished in various ways to complement the overall aesthetic of the structure. In conclusion, stainless steel angles contribute significantly to the overall versatility of a structure through their structural support, flexibility in design, resistance to corrosion and fire, low-maintenance nature, and aesthetic appeal. Their inclusion in construction projects ensures the strength, durability, and longevity of the structure while providing a wide range of design possibilities.

- Q: Can stainless steel angles be used in defense industries?

- Yes, stainless steel angles can be used in defense industries. Stainless steel is known for its high strength, durability, and resistance to corrosion, making it an ideal choice for various applications in defense industries. Stainless steel angles can be used in the construction of military vehicles, aircraft, naval vessels, and other defense equipment. They can also be used in the manufacturing of weapon systems, armor plating, and structures that require high strength and reliability. Additionally, stainless steel angles offer excellent heat resistance, making them suitable for applications involving extreme temperatures or exposure to fire. Overall, stainless steel angles are widely used in defense industries due to their superior mechanical properties and ability to withstand harsh environmental conditions.

- Q: What are the weight capacities of stainless steel angles?

- The weight capacities of stainless steel angles vary depending on various factors such as the size, thickness, and grade of the stainless steel angle. Generally, stainless steel angles have high load-bearing capacities due to their inherent strength and durability. However, it is crucial to consult the manufacturer's specifications or engineering calculations to determine the exact weight capacity of a specific stainless steel angle. Additionally, factors such as the support structure and the distribution of the load also need to be considered when determining the weight capacity of stainless steel angles in practical applications.

- Q: Can stainless steel angle be used in structural applications?

- Stainless steel angle is indeed applicable in structural purposes. Renowned for its robustness, longevity, and ability to combat corrosion, stainless steel is ideal for diverse structural applications. Frequently employed for providing support, reinforcement, and stability, stainless steel angle finds its place in constructions, bridges, and other infrastructure undertakings. It proves particularly valuable in load-bearing situations where strength and stability are paramount. Moreover, stainless steel angle comes in various dimensions, grades, and finishes, granting versatility and customization to cater to particular structural needs.

- Q: Can stainless steel angles be used in the production of machinery frames?

- Yes, stainless steel angles can be used in the production of machinery frames. Stainless steel is a durable and corrosion-resistant material, making it ideal for applications where strength and longevity are required, such as machinery frames. The angular shape of stainless steel angles allows for structural support and reinforcement in machinery frames, ensuring stability and reliability in their operation.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

430 Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords