Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Angles

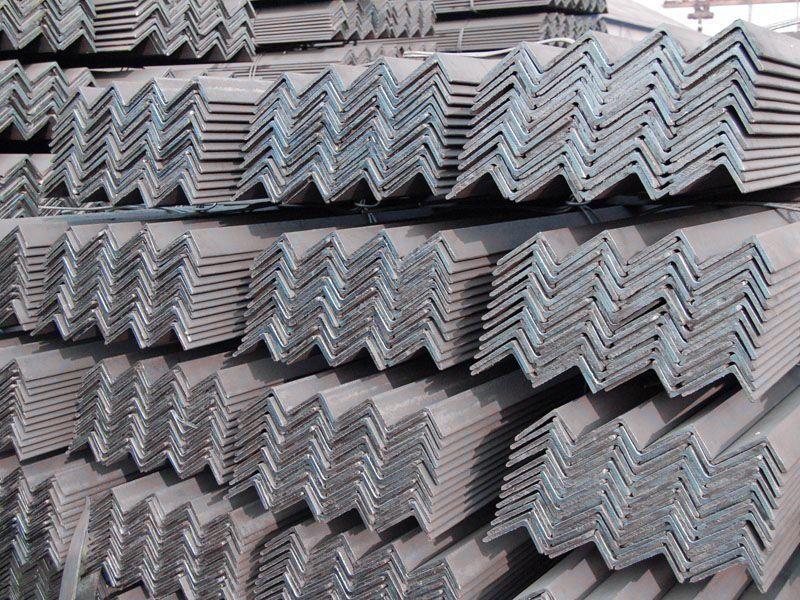

1.Grade: SS200,300,400 series

2.Size: 25×25×3 mm-100×100×10mm

3.Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package:Standard Export Packing, or put into wooden boxes according to your

requirement

10. Application: Construction, Marine, Industry and so on

|

Name |

Stainless Steel Angles | ||||||

|

Standard |

ASTM A554, A312, A249, A269 and A270 | ||||||

|

Material Grade |

304,316,201,202, 316L,430 | ||||||

|

Length |

6m or as customers' request | ||||||

|

Tolerance |

a) thickness: +/-0. 15mm | ||||||

|

| |||||||

|

b) Length:+/-4. 5mm - 0mm | |||||||

|

Surface |

180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

|

Application |

Decoration construction, upholstery, industry instruments | ||||||

|

Test |

Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

|

Chemical Composition of Material |

Composition

Material |

201 |

202 |

304 |

316L |

430 | |

|

C |

≤0.15 |

≤0.15 |

≤0.08 |

≤0.08 |

≤0.12 | ||

|

Si |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 | ||

|

Mn |

5.5-7.5 |

7.5-10 |

≤2.00 |

≤2.00 |

≤1.00 | ||

|

P |

≤0.06 |

≤0.06 |

≤0.045 |

≤0.045 |

≤0.040 | ||

|

S |

≤0.03 |

≤0.03 |

≤0.030 |

≤0.030 |

≤0.030 | ||

|

Cr |

16-18 |

17-19 |

18-20 |

16-18 |

16-18 | ||

|

Ni |

3.5-5.5 |

4-6 |

8-10.5 |

10-14 |

| ||

|

Mo |

|

|

|

2.0-3.0 |

| ||

|

Mechanical Property |

Material Item |

201 |

202 |

304 |

316L | ||

|

Tensile Strength |

≥535 |

≥520 |

≥520 |

≥520 | |||

|

Yield Strength |

≥245 |

≥205 |

≥205 |

≥205 | |||

|

Extension |

≥30% |

≥30% |

≥35% |

≥35% | |||

|

Hardness (HV) |

<253 |

<253 |

<200 |

<200 | |||

- Q: What are the different surface finishes for decorative stainless steel angles?

- Some common surface finishes for decorative stainless steel angles include brushed, polished, satin, and mirror finishes.

- Q: Can stainless steel angles be used in medical equipment?

- Indeed, medical equipment can indeed incorporate stainless steel angles. The medical industry widely embraces stainless steel owing to its exceptional resistance to corrosion, formidable strength, and enduring nature. Surgical instruments, orthopedic implants, medical devices, and hospital equipment are frequently crafted from this sought-after material. By employing stainless steel angles, medical equipment can benefit from enhanced structural support and stability, thus guaranteeing their longevity and dependability. Furthermore, stainless steel can be effortlessly cleansed and sterilized, a pivotal aspect in upholding a sanitary environment within healthcare facilities.

- Q: How do you determine the torsional strength of a stainless steel angle?

- The torsional strength of a stainless steel angle can be determined through torsion testing, which involves applying a twisting force to the angle until it reaches its maximum resistance or failure point. This test is typically conducted using a torsion testing machine that measures the torque and angle of rotation. The torsional strength can then be calculated by dividing the maximum torque applied by the maximum angle of rotation before failure.

- Q: Are stainless steel angles suitable for the production of architectural signage?

- Yes, stainless steel angles are suitable for the production of architectural signage. Stainless steel is a durable and corrosion-resistant material that can withstand outdoor conditions, making it ideal for signage that needs to be long-lasting and withstand the elements. The angles provide structural support and can be easily welded or fastened together to create customized sign designs. Additionally, stainless steel has a sleek and modern appearance that can enhance the aesthetic appeal of architectural signage.

- Q: What are the different types of stainless steel angles connections?

- There are several different types of stainless steel angle connections that are commonly used in various applications. 1. Welded Connections: This is the most common type of connection used for stainless steel angles. It involves welding the two angles together, creating a strong and durable joint. Welded connections are suitable for both structural and non-structural applications. 2. Bolted Connections: In this type of connection, stainless steel angles are secured together using bolts and nuts. This allows for easy disassembly and reassembly if needed. Bolted connections are commonly used in applications where frequent adjustments or modifications are required. 3. Riveted Connections: Riveting involves using a rivet, a permanent mechanical fastener, to join two stainless steel angles together. Riveted connections are known for their strength and reliability. They are often used in heavy-duty applications that require high load-bearing capacity. 4. Adhesive Connections: Adhesives can also be used to bond stainless steel angles together. This type of connection is typically used in applications where welding or drilling is not feasible or desired. Adhesive connections offer flexibility and can be easily applied or removed. 5. Mechanical Connections: Mechanical connections involve using connectors such as brackets, cleats, or plates to join stainless steel angles together. These connectors are typically attached using screws, bolts, or other fasteners. Mechanical connections are commonly used in applications that require quick and easy installation or disassembly. Each type of connection has its own advantages and disadvantages, and the choice depends on factors such as the application requirements, load-bearing capacity, ease of installation, and budget. It is important to consider the specific needs of the project and consult with professionals to determine the most suitable type of stainless steel angle connection.

- Q: Are stainless steel angles resistant to saltwater?

- Yes, stainless steel angles are highly resistant to saltwater due to their corrosion-resistant properties.

- Q: Can stainless steel angle be bent or formed?

- Yes, stainless steel angle can be bent or formed using specialized equipment and techniques such as bending machines or cold forming processes.

- Q: Are stainless steel angles suitable for marine environments?

- Yes, stainless steel angles are suitable for marine environments. Stainless steel is highly resistant to corrosion and rusting, making it an ideal material for use in marine environments where exposure to saltwater and moisture is common. Stainless steel angles offer excellent durability, strength, and longevity, making them a reliable choice for various marine applications.

- Q: How does stainless steel angle perform in corrosive liquids?

- Stainless steel angle is known for its exceptional corrosion resistance properties, making it highly suitable for use in corrosive liquid environments. The alloying elements present in stainless steel, such as chromium, nickel, and molybdenum, form a protective oxide layer on the surface of the material, which acts as a barrier against corrosive substances. This oxide layer, also known as the passive layer, prevents the underlying metal from coming into direct contact with corrosive liquids, effectively shielding it from damage. It is this characteristic that enables stainless steel angle to perform exceptionally well in corrosive liquid environments. Moreover, the specific grade of stainless steel used in the manufacturing of the angle also plays a crucial role in its performance. Certain grades, such as 316 stainless steel, exhibit even higher resistance to corrosion due to their higher content of alloying elements. These grades are particularly useful in highly corrosive environments where the angle may be exposed to aggressive chemicals or saltwater. In summary, stainless steel angle is highly corrosion-resistant and performs excellently in corrosive liquid environments. Its ability to form a protective oxide layer and the presence of alloying elements make it a reliable choice for applications where resistance to corrosion is paramount.

- Q: What is the resistance to fatigue of stainless steel angles?

- Stainless steel angles are widely known for their high resistance to fatigue. Their exceptional strength, durability, and corrosion resistance make them an ideal choice for various applications. Even when subjected to cyclic loading or repetitive stress, stainless steel angles can endure fatigue and maintain their structural integrity over time. Several factors contribute to the fatigue resistance of stainless steel angles. One key factor is the high percentage of chromium in stainless steel, which forms a protective oxide layer on the surface. This layer effectively prevents cracks from forming and spreading, reducing the risk of fatigue failure. In addition, specific heat treatment processes like annealing or cold working are often used during the manufacturing of stainless steel angles. These processes enhance the mechanical properties of the angles, increasing their strength, hardness, and fatigue resistance. It's worth noting that the fatigue resistance of stainless steel angles may vary depending on the grade of stainless steel used, as well as the design and manufacturing techniques employed. To ensure the appropriate selection and application of stainless steel angles for specific fatigue requirements, it is advisable to consult relevant material specifications, industry standards, and engineering guidelines.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2010 |

| Annual Output Value | above US$16 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 30000 square meter |

| No. of Production Lines | above 7 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords