Galvanized U Shaped Channel Steel Beam for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized U Shaped Channel Steel Beam for Construction

Products Information

1.Size | Size : 5#--40# | ||||

2.Length | Lengths : 6m--12m | ||||

3.Standard | Standard : GB, ASTM, JIS, DIN | ||||

4.Grade | Grades : Q235B, Q345B, SS400 | ||||

5.Application | Used or building structures, vehicle | ||||

manufacturing and other industrial structures or construction | |||||

6.Customized Requirement | Can produce special specification products | ||||

as per our customers' requirement | |||||

7.Lead time | 15-30 days after recieving the L/C or pre-paid | ||||

8.Package | Bundles, seaworthy wooden cases with or without | ||||

edge protector, steel hoop and seals, or as per | |||||

customers' requirements | |||||

9.Remark | For detail structure you may check the below drawings and data for know more | ||||

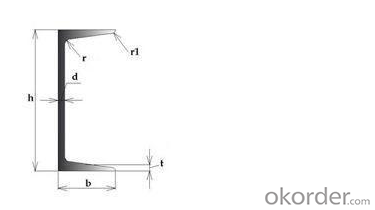

Drawings & Detail Datas

Specification

Specification | h | b | d | t | Cm2 | (kg/m) |

5 | 50 | 37 | 4.5 | 7 | 6.93 | 5.44 |

6.3 | 63 | 40 | 4.8 | 7.5 | 8.45 | 6.63 |

8 | 80 | 43 | 5 | 8 | 10.24 | 8.04 |

10 | 100 | 48 | 5.3 | 8.5 | 12.74 | 10 |

12.6 | 126 | 53 | 5.5 | 9 | 15.69 | 12.37 |

14a | 140 | 58 | 6 | 9.5 | 18.51 | 14.53 |

14b | 140 | 60 | 8 | 9.5 | 21.31 | 16.73 |

16a | 160 | 63 | 6.5 | 10 | 21.95 | 17.23 |

16 | 160 | 65 | 8.5 | 10 | 25.15 | 19.74 |

18a | 180 | 68 | 7 | 10.5 | 25.69 | 20.17 |

18 | 180 | 70 | 9 | 10.5 | 29.29 | 22.99 |

Picture

- Q: Can stainless steel angles be used in staircase construction?

- Yes, stainless steel angles can be used in staircase construction. Stainless steel is a durable and corrosion-resistant material, making it an ideal choice for stairs that are exposed to moisture or other environmental factors. Stainless steel angles can be used to construct the framework of the staircase, providing stability and support. Additionally, stainless steel angles can be easily welded or bolted together, allowing for flexibility in design and easy installation. The sleek and modern appearance of stainless steel also adds an aesthetic appeal to staircase construction. Overall, stainless steel angles are a practical and attractive option for use in staircase construction.

- Q: Now, what's the price of the 201 stainless steel angles?

- The bigger 8# costs 12 yuan a kilo, and the 10# costs 13 yuan a kilo.The price is not including tax, weighing price.

- Q: Can stainless steel angle be used in solar energy applications?

- Yes, stainless steel angle can be used in solar energy applications. Stainless steel is a popular choice for solar energy applications due to its durability, corrosion resistance, and ability to withstand extreme weather conditions. It is commonly used in the construction of solar panel frames, mounting systems, and support structures. The high strength and rigidity of stainless steel angle make it ideal for supporting the weight of solar panels and ensuring the structural integrity of the system. Additionally, stainless steel has low thermal expansion and contraction, which helps maintain the stability of the solar energy system over time. Overall, stainless steel angle is a reliable and long-lasting material for solar energy applications.

- Q: Can stainless steel angles be used for elevator shafts?

- Yes, stainless steel angles can be used for elevator shafts. Stainless steel angles are known for their strength, durability, and resistance to corrosion, making them a suitable choice for elevator shafts. Elevator shafts require materials that can withstand heavy loads and constant use over a long period of time. Stainless steel angles provide the necessary structural support and can withstand the weight and stress associated with elevator operation. Additionally, stainless steel angles are fire-resistant, which is an important safety consideration for elevator shafts. Overall, stainless steel angles are a reliable and practical option for constructing elevator shafts.

- Q: Can stainless steel angles be bent or twisted?

- Stainless steel angles possess the capability to be bent or twisted to a certain extent. Nevertheless, the extent of their flexibility hinges upon various factors including the stainless steel's thickness and grade, as well as the bending or twisting techniques and equipment employed. In general, stainless steel angles exhibit favorable formability traits, enabling them to assume diverse angles and curves. However, caution must be exercised as excessive bending or twisting can compromise their structural strength or lead to cracks. Therefore, it is advisable to seek advice from a professional or consult the manufacturer's guidelines prior to embarking on any attempts to bend or twist stainless steel angles.

- Q: Can stainless steel angles be used in the production of water treatment equipment?

- Yes, stainless steel angles can be used in the production of water treatment equipment. Stainless steel is a corrosion-resistant material that is highly durable and has excellent mechanical properties. These angles can be used to provide structural support and stability to various components of water treatment equipment, such as tanks, pipes, and filters. The corrosion-resistant nature of stainless steel ensures that the angles will not deteriorate or contaminate the water being treated. Additionally, stainless steel is hygienic, easy to clean, and resistant to high temperatures, making it an ideal choice for water treatment applications.

- Q: Can stainless steel angles be used in the production of power transmission equipment?

- Yes, stainless steel angles can be used in the production of power transmission equipment. Stainless steel is widely used in various industries, including power transmission, due to its excellent corrosion resistance, strength, and durability. Stainless steel angles provide structural support and stability in power transmission equipment, ensuring the safe and efficient transmission of power. Additionally, stainless steel angles can withstand high temperatures and harsh environments, making them suitable for use in power transmission applications.

- Q: Can stainless steel angles be used in mining industries?

- Yes, stainless steel angles can be used in mining industries. Stainless steel is known for its high strength, durability, and resistance to corrosion, making it an ideal material for various applications in mining. Stainless steel angles can be used to provide structural support in mining equipment, such as conveyors, crushers, and screens. They can also be used in the construction of processing plants, where they can be incorporated into the infrastructure for platforms, walkways, and support beams. Additionally, stainless steel angles are often utilized in the fabrication of mining tools and equipment, such as drill rods, bolts, and fittings, due to their excellent mechanical properties and resistance to wear and tear. Overall, stainless steel angles are a reliable and cost-effective choice for the demanding and harsh conditions found in mining industries.

- Q: Can stainless steel angles be used in food storage facilities?

- Yes, stainless steel angles can be used in food storage facilities. Stainless steel is known for its excellent resistance to corrosion, making it ideal for use in environments where hygiene and cleanliness are crucial, such as food storage facilities. Additionally, stainless steel has smooth and easy-to-clean surfaces, which further enhances its suitability for food storage.

- Q: How do you calculate the moment of inertia for a slotted stainless steel angle?

- To calculate the moment of inertia for a slotted stainless steel angle, you would need to consider the dimensions and shape of the angle. The moment of inertia is a measure of an object's resistance to changes in rotation and can be determined using the parallel axis theorem. This equation involves integrating the area of the angle about its centroid, which takes into account both the slotted portion and the overall shape of the angle.

Send your message to us

Galvanized U Shaped Channel Steel Beam for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords