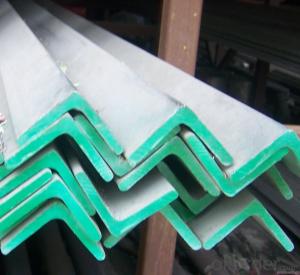

Stainless steel angle; angle steel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Informaiton of Stainless Steel Angle Bar

1. Grade: SS200, 300,400 series

2. Size: 25×25×3 mm-100×100×10mm

3. Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package: Standard Export Packing, or put into wooden boxes according to your requirement

10. Application: Construction, Marine, Industry etc.

Specification of Stainless Steel Angle Bar

Name | Stainless Steel Angles | |||||

Standard | ASTM A554, A312, A249, A269 and A270 | |||||

Material Grade | 304,316,201,202, 316L,430 | |||||

Length | 6m or as customers' request | |||||

Tolerance | a) Thickness: +/-0. 15mm | |||||

b) Length: +/-4. 5mm - 0mm | ||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | |||||

Application | Decoration construction, upholstery, industry instruments | |||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | |||||

Chemical Composition of Material | Composition Material | 201 | 202 | 304 | 316 | 430 |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | |

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | |

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | |

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | |

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | |

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | ||

Mo | 2.0-3.0 | |||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316 | |

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | ||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | ||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | ||

Hardness (HV) | <253 | <253 | <200 | <200 | ||

- Q: Are stainless steel angles resistant to chemicals?

- Yes, stainless steel angles are highly resistant to chemicals. This is due to the unique properties of stainless steel, such as its high chromium content, which forms a protective layer on the surface of the metal. This protective layer, known as the passive film, prevents the metal from reacting with chemicals and corrosive substances. Stainless steel angles are therefore widely used in industries where they come into contact with various chemicals, such as petrochemical, pharmaceutical, and food processing industries. Additionally, stainless steel angles are also resistant to oxidation, making them suitable for use in a wide range of environments, including those with high humidity or extreme temperatures.

- Q: What are the corrosion resistance properties of stainless steel angles?

- Stainless steel angles have excellent corrosion resistance properties due to the presence of chromium, which forms a passive oxide layer on the surface, protecting the steel from oxidation and corrosion in various environments. Additionally, the alloying elements in stainless steel, such as nickel and molybdenum, further enhance its resistance to corrosion, making stainless steel angles highly durable and suitable for applications in corrosive environments.

- Q: Can stainless steel angles be used for framing?

- Yes, stainless steel angles can be used for framing. Stainless steel is known for its strength, durability, and corrosion resistance, making it a suitable material for various construction applications. Stainless steel angles, with their L-shaped profile, provide structural support and stability when used in framing projects. They can be used to create frames for doors, windows, cabinets, shelving units, and other structural elements. Stainless steel angles offer excellent load-bearing capacity and can withstand heavy weights, making them ideal for framing applications that require strength and durability. Additionally, stainless steel angles have a sleek and modern appearance, adding an aesthetic appeal to any framing project.

- Q: What is the difference between 316 and 316H stainless steel angles?

- The carbon content sets 316 and 316H stainless steel angles apart. While both alloys share the same levels of chromium, nickel, and molybdenum, 316H stainless steel angles have a greater amount of carbon compared to 316 stainless steel angles. The elevated carbon content in 316H stainless steel angles bestows them with heightened strength and resistance to deformation at high temperatures. Consequently, 316H is better suited for applications where elevated temperatures are of concern, such as in the petrochemical, chemical, and power generation industries. Conversely, 316 stainless steel angles find common use in general applications that prioritize high resistance against corrosion. Its exceptional corrosion and pitting resistance make it widely employed in marine environments, food processing equipment, and medical devices. To summarize, the disparity between 316 and 316H stainless steel angles lies in their carbon content. 316H possesses a greater amount of carbon, enhancing its strength and resistance to deformation at high temperatures, while 316 is favored for its extraordinary resistance to corrosion. The choice between the two hinges on the specific requirements of the intended application.

- Q: Are stainless steel angles available in different colors?

- No, stainless steel angles are not available in different colors. Stainless steel is a material known for its silver or grayish color, which is a result of the steel alloy used in its composition. While stainless steel can be polished or brushed to achieve different finishes or textures, the base color remains the same. However, if you are looking for angles in different colors, there are other materials such as aluminum or plastic that can be coated or painted to match your desired color scheme.

- Q: Are stainless steel angles suitable for the production of handrails?

- Yes, stainless steel angles are suitable for the production of handrails. Stainless steel is a highly durable and corrosion-resistant material, making it ideal for outdoor applications such as handrails. The angles provide structural support and stability to the handrails, ensuring they can withstand the necessary loads and provide a safe grip for users. Additionally, stainless steel angles can be easily fabricated and customized to meet specific design requirements, allowing for a wide range of handrail styles and configurations. Overall, stainless steel angles offer a reliable and visually appealing option for the production of handrails.

- Q: What are the maximum load capacities of stainless steel angles?

- The maximum load capacities of stainless steel angles vary depending on several factors such as the grade and thickness of the stainless steel, the length of the angle, and the specific application. It is best to consult engineering and technical specifications or consult a structural engineer for accurate load capacity information.

- Q: How do you calculate the shear strength of a rounded corner stainless steel angle?

- To calculate the shear strength of a rounded corner stainless steel angle, you would need to consider the material properties and dimensions of the angle. The shear strength can be determined using the formula: Shear Strength = 0.6 * Yield Strength, where the yield strength is the maximum stress that the material can withstand without permanent deformation. Additionally, the dimensions of the angle, such as the thickness and length, will also affect the shear strength calculation.

- Q: What are the different types of fasteners used with stainless steel angles?

- There are several types of fasteners commonly used with stainless steel angles. Some of the most popular options include screws, bolts, nuts, and washers. These fasteners are typically made from stainless steel as well, ensuring compatibility with the angles and providing resistance to corrosion. Screws are a versatile choice, available in various sizes and lengths, and can be used to secure stainless steel angles to other materials or to join multiple angles together. They typically feature a threaded shaft that allows for easy installation and removal. Bolts are similar to screws but generally have a larger size and a more robust construction. They are commonly used in heavy-duty applications where additional strength and stability are required. Bolts often require nuts and washers to secure them in place. Nuts are used in conjunction with bolts and screws to secure the fastener in place. They come in different shapes and sizes, including hexagonal, square, and wing nuts. Stainless steel nuts are designed to provide a secure and reliable connection, ensuring the angles remain firmly in position. Washers are flat, thin pieces of metal that are placed between the fastener and the surface of the stainless steel angle. Their primary purpose is to distribute the load and prevent damage to the angle by providing a larger surface area for the fastener to bear against. Washers also help to improve the fastener's grip and prevent loosening over time. When choosing the type of fastener to use with stainless steel angles, it is crucial to consider the specific application, load requirements, and environmental conditions. It is recommended to consult with a professional or refer to the manufacturer's guidelines to ensure the correct type and size of fastener are selected for optimal performance and durability.

- Q: How are stainless steel angles used in construction?

- Stainless steel angles are widely used in construction for various purposes. One of the primary applications of stainless steel angles in construction is for structural support. These angles are commonly used as beams, lintels, and columns to provide strength and stability to buildings and infrastructure. Stainless steel angles are preferred in construction due to their excellent corrosion resistance and high durability. They are capable of withstanding harsh environmental conditions, making them suitable for both indoor and outdoor applications. The corrosion resistance of stainless steel angles ensures that they maintain their structural integrity over time, even in highly corrosive environments such as coastal regions or chemical plants. In addition to structural support, stainless steel angles also find applications in architectural designs. They are often used as decorative elements in building facades, handrails, and staircases, adding an aesthetic appeal to the overall design. The versatility of stainless steel angles allows architects and designers to create unique shapes and structures that can enhance the visual appeal of a construction project. Furthermore, stainless steel angles are utilized in construction for their ease of fabrication and installation. They can be easily cut, drilled, welded, and shaped to meet the specific requirements of a project. This flexibility not only simplifies the construction process but also allows for cost-effective customization. Overall, stainless steel angles play a vital role in construction by providing structural support, architectural design elements, and durability. Their corrosion resistance, versatility, and ease of fabrication make them a preferred choice in various construction projects, ranging from residential buildings to commercial complexes and industrial facilities.

Send your message to us

Stainless steel angle; angle steel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords