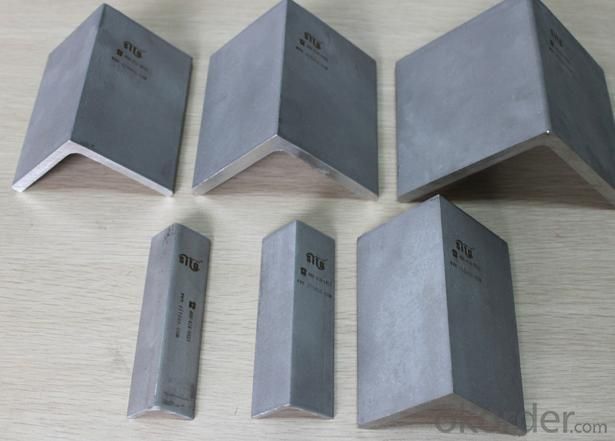

Polished Unequal Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Angles

1.Grade: SS200,300,400 series

2.Size: 25×25×3 mm-100×100×10mm

3.Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package:Standard Export Packing, or put into wooden boxes according to your

requirement

10. Application: Construction, Marine, Industry and so on

|

Name |

Stainless Steel Angles | ||||||

|

Standard |

ASTM A554, A312, A249, A269 and A270 | ||||||

|

Material Grade |

304,316,201,202, 316L,430 | ||||||

|

Length |

6m or as customers' request | ||||||

|

Tolerance |

a) thickness: +/-0. 15mm | ||||||

|

| |||||||

|

b) Length:+/-4. 5mm - 0mm | |||||||

|

Surface |

180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

|

Application |

Decoration construction, upholstery, industry instruments | ||||||

|

Test |

Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

|

Chemical Composition of Material |

Composition

Material |

201 |

202 |

304 |

316L |

430 | |

|

C |

≤0.15 |

≤0.15 |

≤0.08 |

≤0.08 |

≤0.12 | ||

|

Si |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 | ||

|

Mn |

5.5-7.5 |

7.5-10 |

≤2.00 |

≤2.00 |

≤1.00 | ||

|

P |

≤0.06 |

≤0.06 |

≤0.045 |

≤0.045 |

≤0.040 | ||

|

S |

≤0.03 |

≤0.03 |

≤0.030 |

≤0.030 |

≤0.030 | ||

|

Cr |

16-18 |

17-19 |

18-20 |

16-18 |

16-18 | ||

|

Ni |

3.5-5.5 |

4-6 |

8-10.5 |

10-14 |

| ||

|

Mo |

|

|

|

2.0-3.0 |

| ||

|

Mechanical Property |

Material Item |

201 |

202 |

304 |

316L | ||

|

Tensile Strength |

≥535 |

≥520 |

≥520 |

≥520 | |||

|

Yield Strength |

≥245 |

≥205 |

≥205 |

≥205 | |||

|

Extension |

≥30% |

≥30% |

≥35% |

≥35% | |||

|

Hardness (HV) |

<253 |

<253 |

<200 |

<200 | |||

- Q:Are stainless steel angles suitable for staircases?

- Yes, stainless steel angles are suitable for staircases. Stainless steel is a durable and corrosion-resistant material, making it an excellent choice for staircase construction. Stainless steel angles provide strength and stability to the staircase structure, ensuring safety for users. Additionally, stainless steel angles can be easily fabricated and customized to fit the specific design requirements of the staircase. With their sleek and modern appearance, stainless steel angles can also enhance the aesthetics of the staircase, adding a contemporary touch to the overall design.

- Q:Can stainless steel angles be used for balcony grilles?

- Yes, stainless steel angles can be used for balcony grilles. Stainless steel is a popular choice for balcony grilles due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel angles provide structural support and strength to the grilles, making them suitable for use in balconies. Additionally, stainless steel angles can be easily fabricated and customized to meet specific design requirements for balcony grilles. Overall, stainless steel angles are a reliable and long-lasting option for balcony grilles.

- Q:What are the load-bearing capacities of stainless steel angles?

- The load-bearing capacities of stainless steel angles can vary due to various factors including the size, shape, and grade of the angle, as well as the specific application and environmental conditions. In structural applications where strength and corrosion resistance are necessary, stainless steel angles are commonly utilized. They are frequently employed as supports or brackets in construction, industrial, and architectural projects. The cross-sectional area of a stainless steel angle determines its load-bearing capacity. This area is influenced by the angle's dimensions, such as the material thickness and leg length. Furthermore, the load-bearing capacity can be affected by the grade of stainless steel used, as different grades possess distinct mechanical properties. To accurately determine the load-bearing capacity of a particular stainless steel angle, referencing engineering resources like design manuals, technical specifications, or consulting with a structural engineer is necessary. These resources provide guidelines and formulas for calculating the safe load capacity based on the angle's specific dimensions and material properties. It is crucial to emphasize that load-bearing capacities should always be determined by a qualified professional to avoid structural failure or safety hazards caused by incorrect calculations or assumptions.

- Q:What are the different alloying elements in stainless steel angles?

- Stainless steel angles are primarily made up of iron and carbon, but they also contain alloying elements that enhance their properties. The main alloying elements found in stainless steel angles include: 1. Chromium: This is the most important alloying element in stainless steel angles. It provides corrosion resistance and increases the strength and hardness of the material. 2. Nickel: Nickel improves the corrosion resistance of stainless steel angles, especially in acidic environments. It also enhances the ductility and toughness of the material. 3. Molybdenum: Molybdenum increases the resistance to pitting and crevice corrosion in stainless steel angles. It also improves the material's strength at high temperatures. 4. Manganese: Manganese is added to enhance the workability and formability of stainless steel angles. It also contributes to their strength and hardness. 5. Titanium: Titanium is used as a stabilizing element in stainless steel angles. It prevents the formation of harmful carbides and improves the resistance to intergranular corrosion. 6. Copper: Copper is added to stainless steel angles to improve their resistance to certain acids and to enhance their heat transfer properties. 7. Nitrogen: Nitrogen is used as a strengthening agent in stainless steel angles. It improves the material's hardness and corrosion resistance. These alloying elements, along with the proper ratio of iron and carbon, contribute to the various grades and types of stainless steel angles available in the market. Each grade is designed to meet specific requirements in terms of corrosion resistance, strength, and other mechanical properties.

- Q:What is the resistance to scaling of stainless steel angles?

- Stainless steel angles have a high resistance to scaling due to the presence of chromium in their composition, which forms a protective oxide layer on the surface. This oxide layer prevents the steel from reacting with oxygen, preventing the formation of scales even at high temperatures.

- Q:Are stainless steel angles suitable for outdoor furniture?

- Yes, stainless steel angles are suitable for outdoor furniture. Stainless steel is highly resistant to corrosion and rust, making it an ideal material for outdoor applications. It can withstand exposure to various weather conditions, including rain, humidity, and sunlight, without deteriorating or losing its structural integrity. Additionally, stainless steel is known for its strength and durability, ensuring that outdoor furniture made from this material will be able to withstand heavy use and remain stable over time. Furthermore, stainless steel angles can be easily cleaned and maintained, making them a practical choice for outdoor furniture where dirt, dust, and other debris are likely to accumulate. Overall, stainless steel angles are a reliable and long-lasting option for creating durable and stylish outdoor furniture.

- Q:How do you prevent distortion when welding stainless steel angles?

- To prevent distortion when welding stainless steel angles, it is important to carefully plan and prepare the welding process. Some key steps include using the correct welding technique, properly clamping or fixturing the angles to minimize movement, controlling the heat input, and applying intermittent welding technique to avoid excessive heat buildup. Additionally, using a lower welding current and smaller weld beads can help reduce distortion.

- Q:Can stainless steel angles be used in agricultural machinery?

- Yes, stainless steel angles can be used in agricultural machinery. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for various applications in the agricultural industry. Stainless steel angles can be used in the construction of machinery frames, supports, brackets, and other structural components. The excellent strength and resistance to rust and corrosion make stainless steel angles ideal for withstanding the harsh conditions and exposure to moisture and chemicals commonly found in agricultural environments. Additionally, stainless steel is easy to clean and maintain, ensuring a longer lifespan for the machinery.

- Q:What are the common uses of 90-degree stainless steel angles?

- 90-degree stainless steel angles are commonly used in construction and structural applications. They provide stability and support in the construction of frames, brackets, and corners. These angles are also used in manufacturing for creating shelves, racks, and other storage systems. Additionally, they find applications in architectural projects for creating decorative elements such as trims, moldings, and edge protection.

- Q:What are the different surface finishes available for stainless steel angles?

- There are several different surface finishes available for stainless steel angles. Some of the most common finishes include: 1. Mill Finish: This is the basic finish that is achieved when the stainless steel angle is produced in the mill. It has a dull, gray appearance, with no additional treatment or polishing. 2. Brushed Finish: Also known as satin finish, this surface finish is achieved by brushing the stainless steel angle with a fine abrasive material. It creates a smooth, brushed appearance that hides fingerprints and scratches well. 3. Mirror Finish: This is the most reflective surface finish available for stainless steel angles. It is achieved by polishing the angle with progressively finer abrasives until a highly reflective surface is achieved. Mirror finish is commonly used in architectural applications and for decorative purposes. 4. Bead Blasted Finish: This surface finish is created by bombarding the stainless steel angle with small glass beads at high velocity. It creates a uniform, non-reflective, textured surface that can hide imperfections and is often used in industrial applications. 5. Etched Finish: In this finish, the stainless steel angle is chemically treated to create a pattern or design on the surface. It can be used to create logos, text, or decorative patterns. 6. Colored Finish: Stainless steel angles can also be colored using various techniques such as PVD (Physical Vapor Deposition) coating or electroplating. These finishes create a range of colors and can be used to enhance the aesthetic appeal of the angle. The choice of surface finish for stainless steel angles depends on the intended application, desired appearance, and level of corrosion resistance required. Each finish has its advantages and disadvantages, and it is important to consider these factors when selecting the appropriate finish for a specific project.

1. Manufacturer Overview |

|

|---|---|

| Location | Wuxi,China |

| Year Established | 2003 |

| Annual Output Value | Above US$8.3 Million |

| Main Markets | SouthEast Asia |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 30 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above21,000 square meters |

| No. of Production Lines | Above 7 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Polished Unequal Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords